Self-vibration type continuous casting system

A casting system and self-vibration technology, applied in ingot workshops, foundry workshops, casting equipment, etc., can solve the problem of metal ingots falling off and not clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

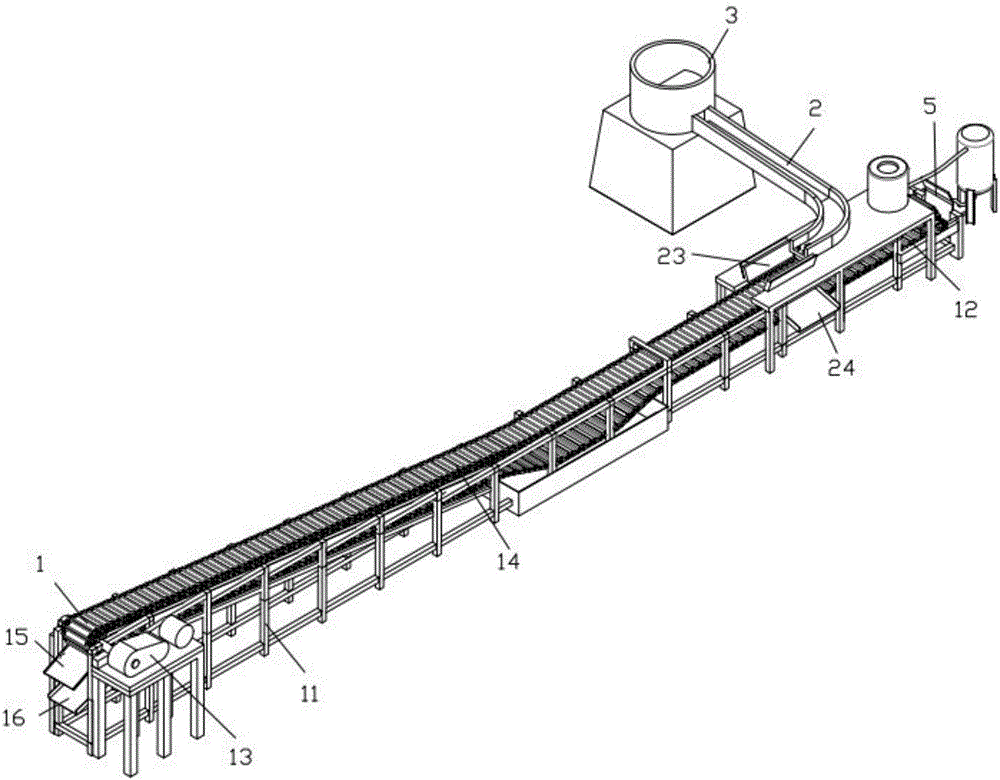

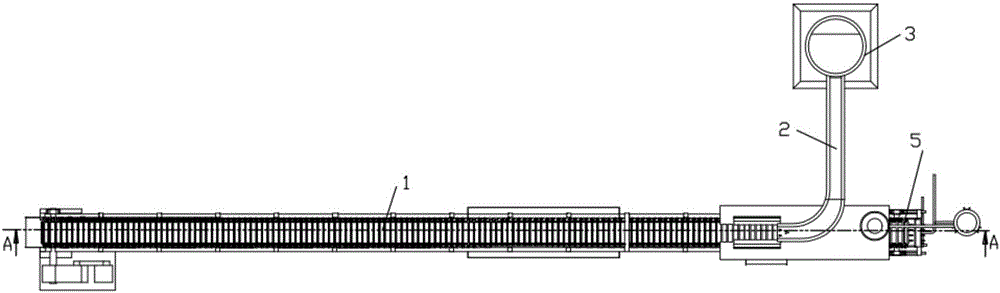

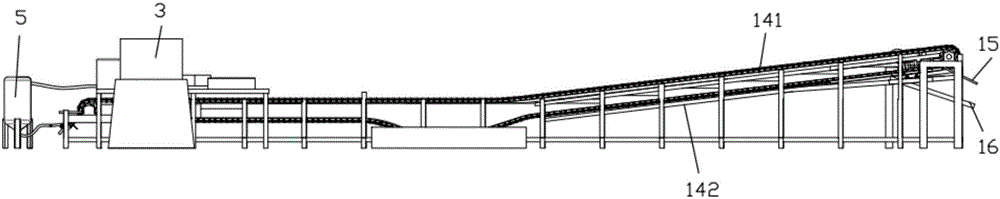

[0028] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

[0029] see figure 1 , figure 2 , the embodiment of the present invention provides a self-vibrating continuous casting system, including a casting machine 1, a flow diversion device 2, a molten pool 3, and a self-vibration device 4, one end of the flow diversion device 2 is connected to the molten pool 3, and the other end of the flow diversion device 2 One end is connected with the casting machine 1. The casting machine 1 includes a support frame 11, a machine head 12 fixed on the support frame 11, a machine tail 13, and a casting par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com