Automatic sprayer and control method thereof

A sprayer, automatic technology, applied in spraying devices, manufacturing tools, casting and molding equipment, etc., can solve the problems of low work efficiency, high price, unable to spray amount and spraying time control and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0187] It will be described in conjunction with FIG. 10 .

[0188] First, the power supply circuit will be described. AC 380V / 50Hz is a three-phase AC power grid with a line voltage of 380 volts, a frequency of 50 Hz, and a phase voltage of 220 volts. U, V, W are the three phase wires, N is the neutral wire, PE is the safety ground wire, and K1 is the main switch of the AC power supply.

[0189] ZL is a direct current power supply, and DC24V is a direct current of 24 volts.

[0190] The 220V AC mains is sent to the input terminal of the DC power supply, and the output terminal of the DC power supply outputs a 24-volt DC power, and the DC power is sent to the signal circuit, control circuit, conversion circuit, executive components, and man-machine interface device through the line.

[0191] Second, the control circuit and its related circuits will be described. In this embodiment, the intelligent controller used by the control circuit is PCL. PCL is a programmable controll...

Embodiment 2

[0198] It will be described with reference to FIG. 11 .

[0199] The labels in the figure will be explained first. 2 is cylinder, 21 is blowing valve, 24 is atomizer, 25 is air control valve, 26 is spray block, 27 is nozzle, DXF is one-way valve, GLQ is filter, JYF-1 is pressure reducing valve, JYF-2 is a pressure reducing valve, JXQ is a shut-off muffler, KYJ is an air compressor, KGQ is an air filter, TDCF is a release agent solenoid valve, RQ is a container, TJF is a water volume adjustment switch, WDCF is an atomization solenoid valve, XZD is a rotary solenoid valve and YLB is a pressure gauge.

[0200] Figure 11 is used to illustrate the basic principle of the gas circuit. When implementing the present invention, the atomizer 24 and various solenoid valves and the like are not limited to two sets, and more can also be used.

Embodiment 3

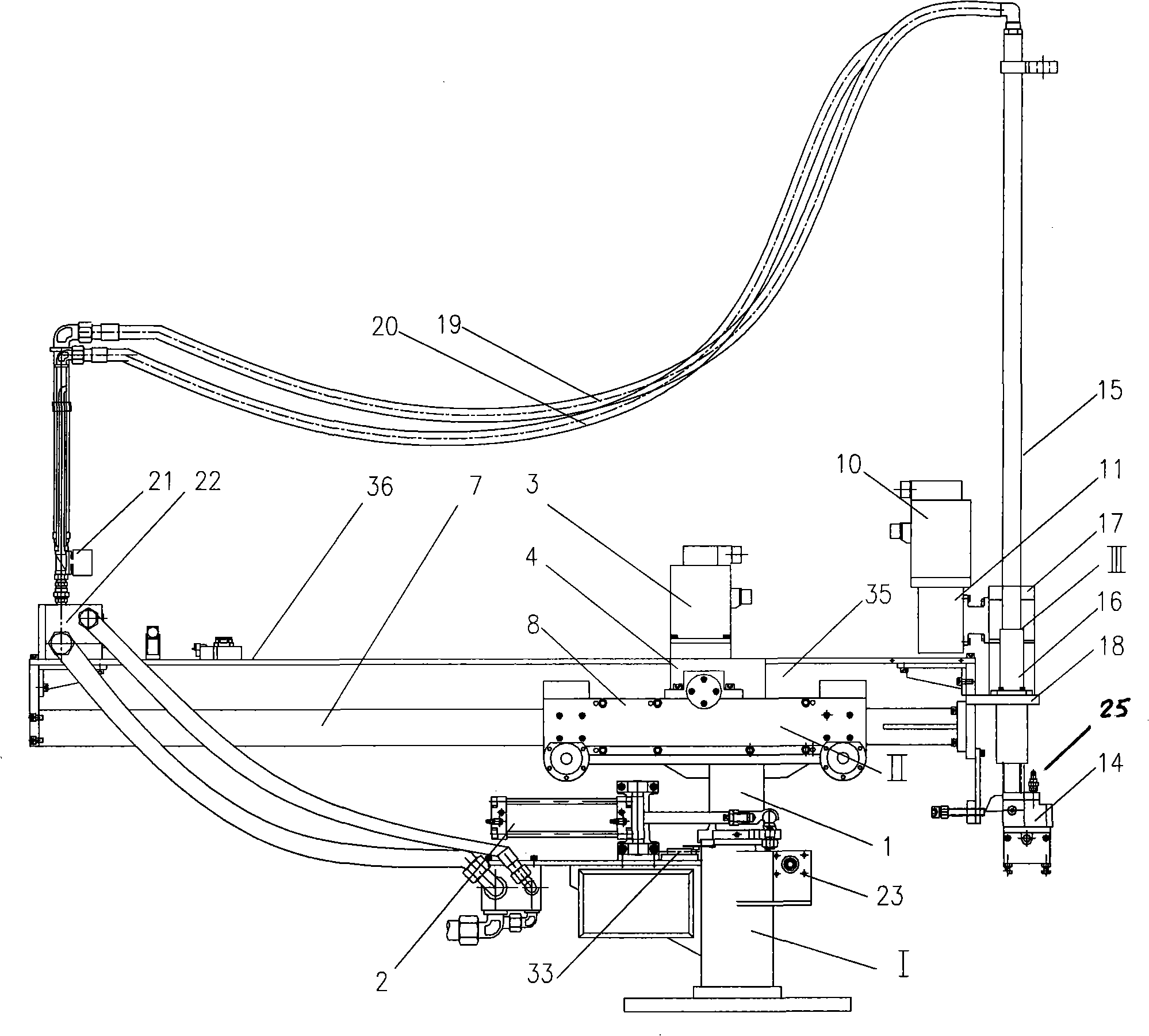

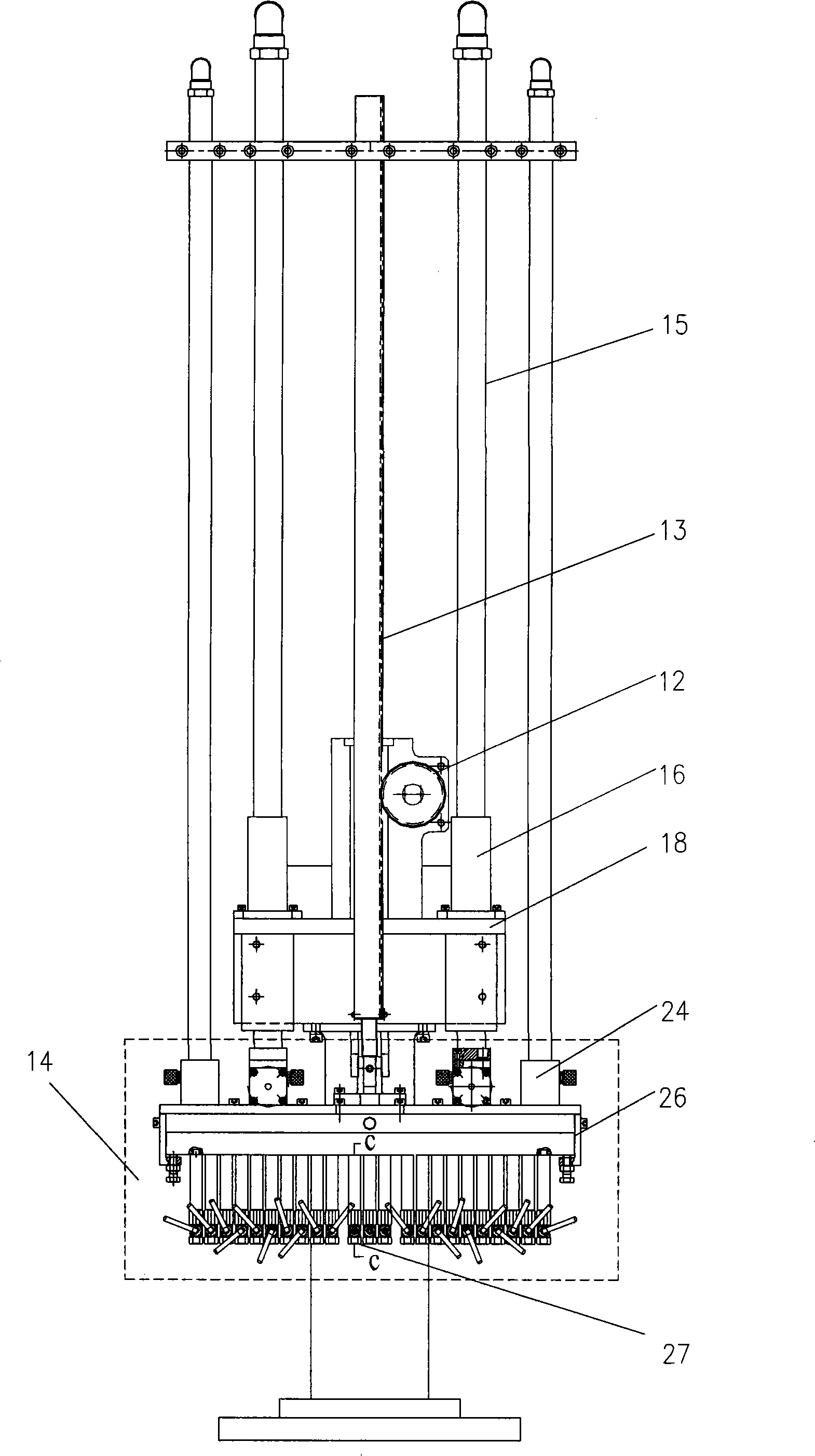

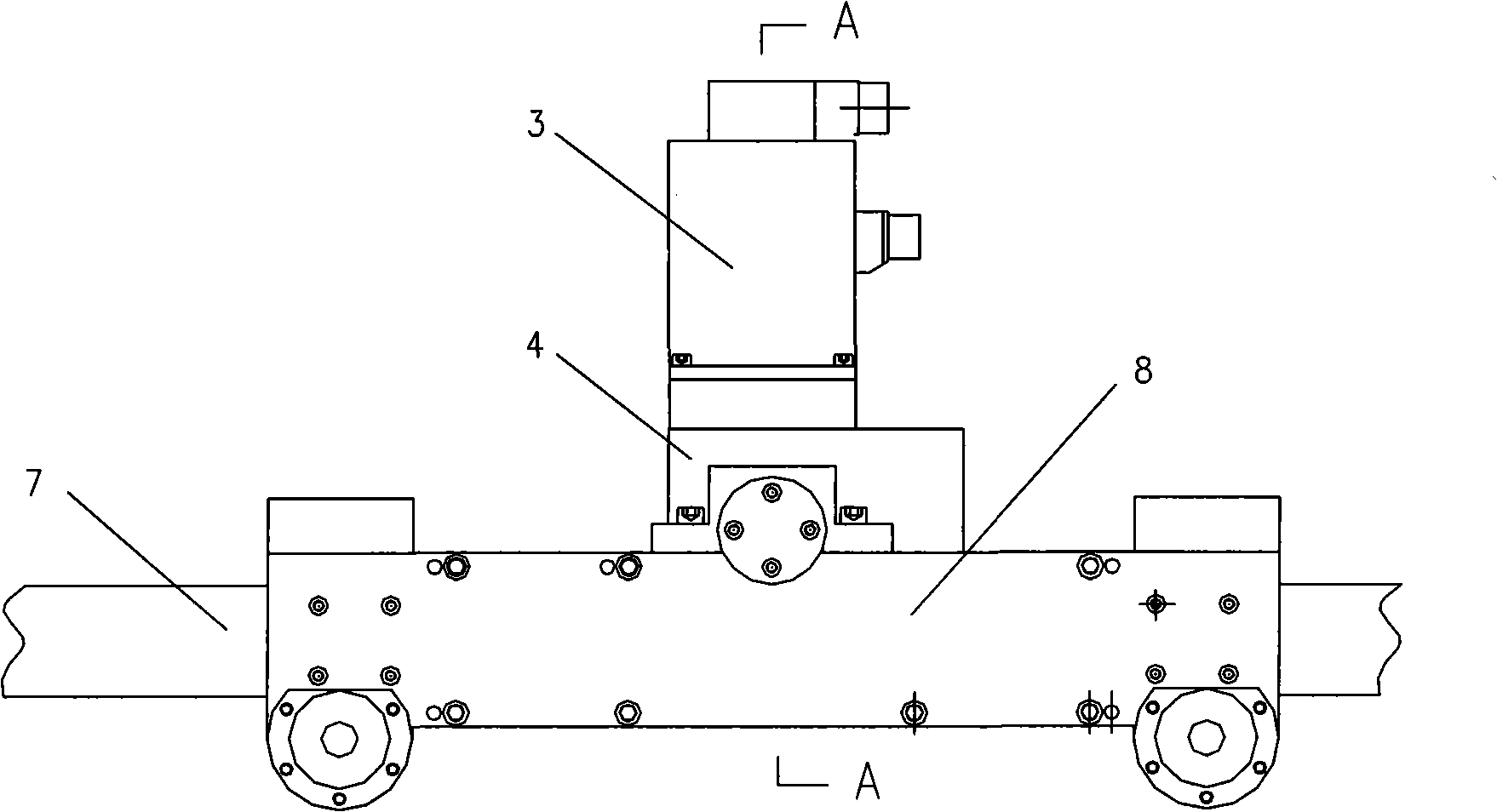

[0202] combine Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 ,Be explained. The above 6 figures are schematic diagrams in the top view direction.

[0203] The labels in the figure will be explained first. 14 is a spraying part; 38 is a static mold in a die-casting mold; 39 is a moving mold in a die-casting mold.

[0204] There are two rows of nozzles on the spraying part 14, one row is dedicated to blowing and spraying the static mold, and the other row is dedicated to blowing and spraying the moving mold.

[0205] Die casting machine mold is divided into two parts: static mold and dynamic mold. When die-casting products, the static mold and the dynamic mold are combined, such as Figure 12 shown. After the die-casting of the product is completed, the static mold does not move and the movable mold moves separately, such as Figure 13 As shown, at this time, the product can be unloaded from the gap between the static mold and the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com