Aluminum alloy casting mechanical performance prediction method

A technology for aluminum alloy castings and performance prediction, applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

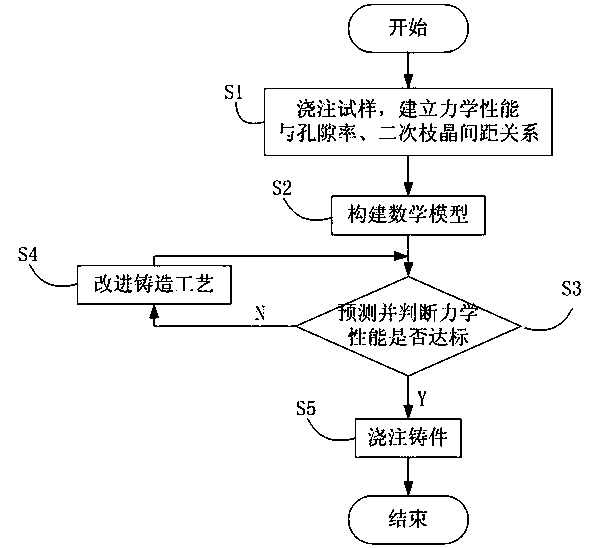

[0040] A method for predicting the mechanical properties of aluminum alloy castings, such as figure 1 shown, including the following steps:

[0041] S1: Pouring the sample to establish the relationship between mechanical properties, porosity and secondary dendrite spacing;

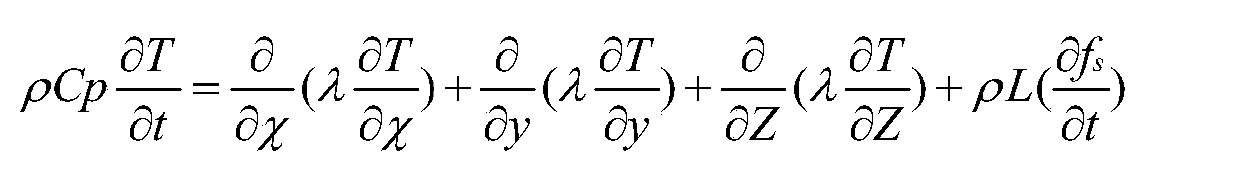

[0042] S2: Construct a mathematical model for the formation of micropores and secondary dendrites during the solidification of castings;

[0043] S3: Predict the values of micropores and secondary dendrites by computer, and predict the mechanical properties of aluminum alloy castings according to the relationship between porosity, secondary dendrite spacing and mechanical properties: tensile strength UTS and elongation δ, if mechanical If the performance is not up to standard, then enter step S4, if the mechanical property is up to standard, then enter step S5;

[0044] S4: Jump to step S3 after improving the casting process;

[0045] S5: Pouring the casting.

[0046] This method studies the influenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com