Coinage-used golden yellow copper alloy material and preparation method thereof

A copper alloy and golden yellow technology is applied in the fields of gold-yellow copper alloy materials for coinage, coinage blanks and various decorative materials, which can solve the problems of high raw material cost, increased difficulty in casting and high Al content, and achieves low raw material, Low manufacturing cost and good ingot quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

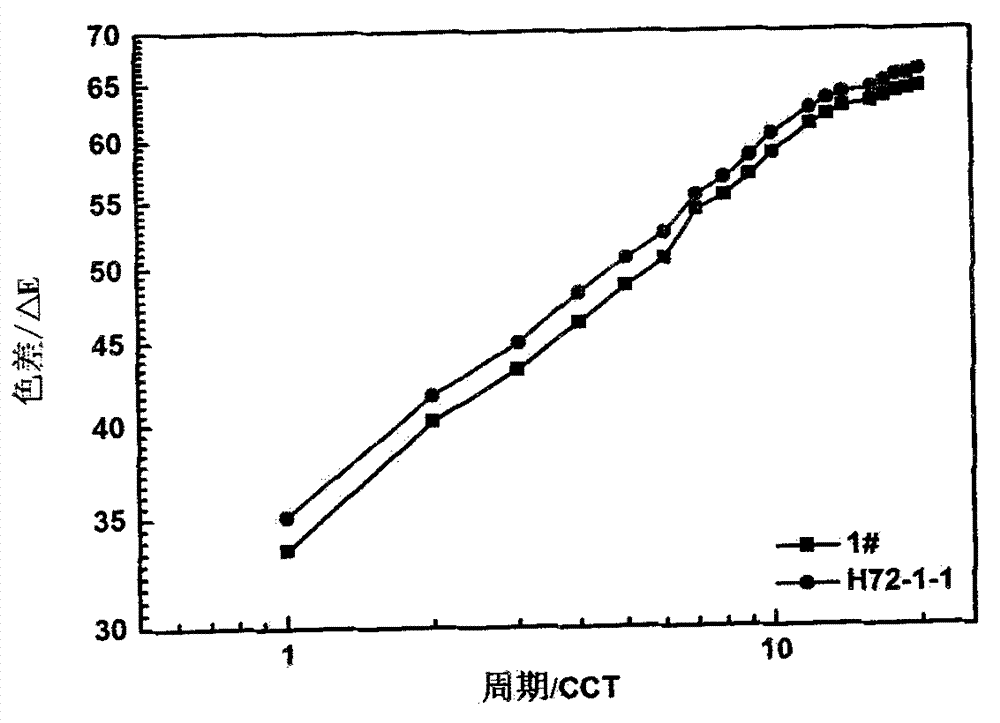

[0033] Example 1: The components are respectively: Cu: 76.0wt%, Al: 1.8wt%, Ni: 0.4wt%, B: 0.005wt%, Ce: 0.05wt%, Si: 0.1wt%, Fe: 0.06wt% , Pb: 0.01wt%, the balance is Zn 1# alloy and Cu: 75.0wt%, Al 2.0wt%, Ni: 0.5wt%, B: 0.003wt%, Ce: 0.08wt%, Si: 0.2wt% , Fe: 0.02wt%, Pb: 0.05wt%, and the 2# alloy whose balance is Zn is smelted and cast according to the above-mentioned preparation method step a to obtain the alloy ingot of the above two components, and then according to step b to obtain the surface-free The ingot with defects was directly cold-rolled, and the deformation amount of one cold-rolling was 60%. The macroscopic appearance of the rolled slab showed no cracks on the surface and edge of the two-component alloy, indicating that the above-mentioned alloy ingot Tissue cold working performance is good. The base cake processed from the two alloys in this example and the existing coinage HSn72-1-1 plate is polished and then tested for gold color with a color difference m...

Embodiment 2

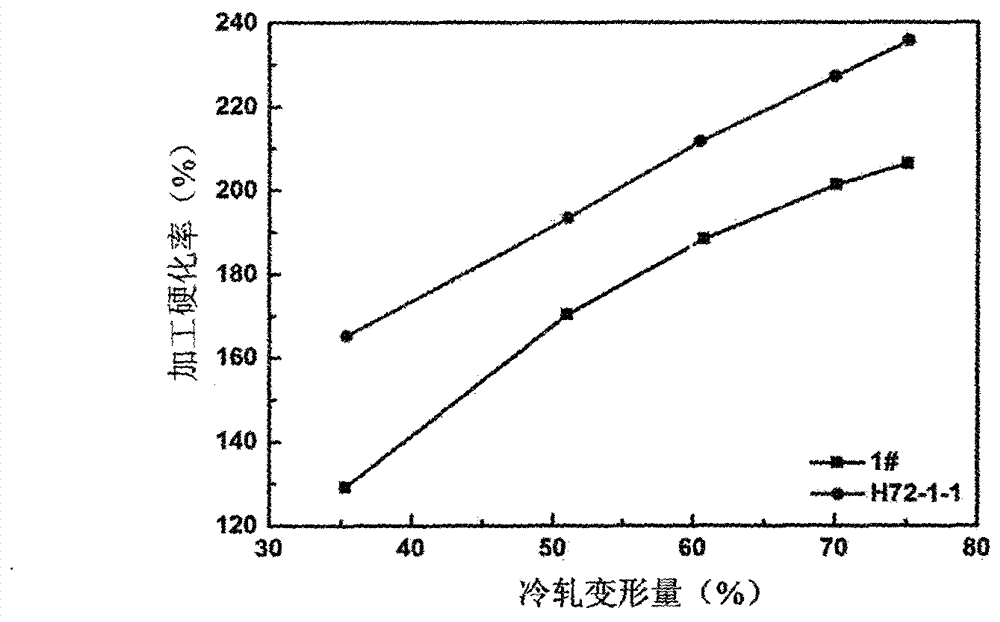

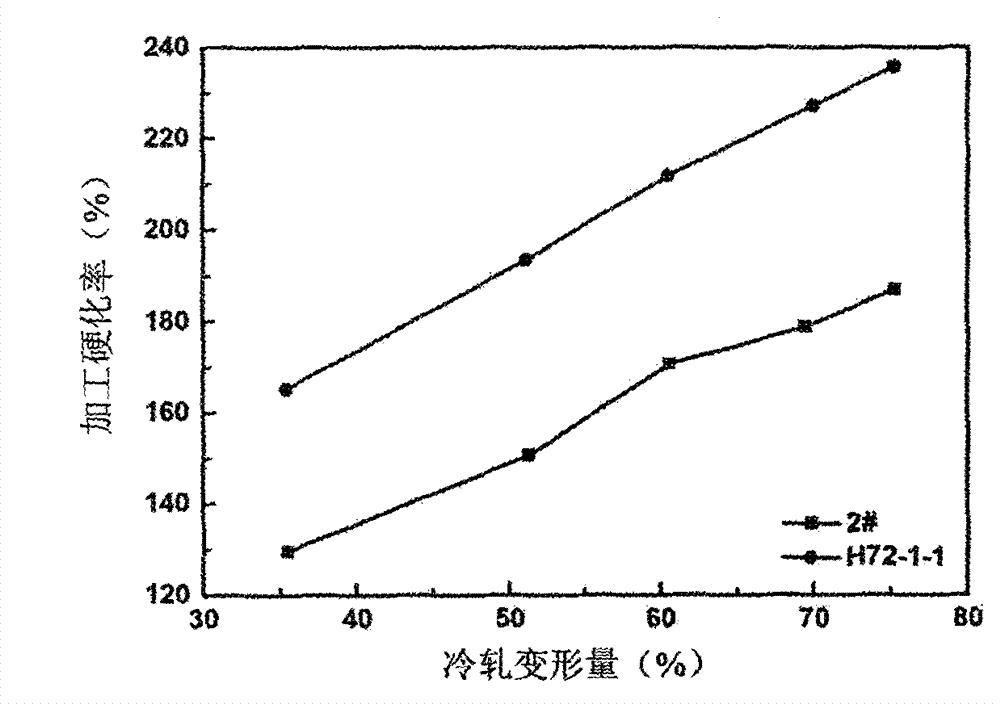

[0037] Example 2: The components are respectively: Cu: 76.0wt%, Al: 1.8wt%, Ni: 0.8wt%, B: 0.005wt%, Ce: 0.003wt%, Si: 0.1wt%, Fe: 0.02wt% , Pb: 0.03wt%, the balance is Zn and unavoidable impurities 1# alloy and Cu: 75.0wt%, Al 2.4wt%, Ni: 0.2wt%, B: 0.01wt%, Ce: 0.1wt%, 2# alloy of Si: 0.2wt%, Fe: 0.01wt%, Pb: 0.01, and the balance is Zn, respectively, according to the above steps a-i to make plates with a thickness of 2mm. The above two kinds of plates and the existing coinage HSn72-1-1 plates are wire-cut into small rectangular pieces with a length of 50 mm and a width of 20 mm, and then processed according to the following process: cold rolling 40% → measuring Vickers hardness (HV) → cold Rolling 20% → measuring Vickers hardness (HV) → cold rolling 20% → measuring Vickers hardness (HV), until about 0.5mm.

[0038] Two kinds of alloys in this embodiment and the base cake processed from the HSn72-1-1 sheet material used for coinage in the present embodiment are processe...

Embodiment 3

[0043] Example 3: The components are respectively: Cu: 76.0wt%, Al: 1.9wt%, Ni: 0.3wt%, B: 0.007wt%, Ce: 0.02wt%, Si: 0.15wt%, Fe: 0.001wt% , Pb: 0.003wt%, the balance is Zn 1# alloy and Cu: 77.0wt%, Al 2.0wt%, Ni: 0.5wt%, B: 0.009wt%, Ce: 0.008wt%, Si: 0.18wt% %, Fe: 0.04wt%, Pb: 0.03wt%, and the balance is Zn 2# alloy, respectively according to the steps a-i in the above preparation method to make a plate with a thickness of 2mm. The above-mentioned two kinds of 1# alloy plate and 2# alloy plate, and the existing HSn72-1-1 plate for coinage are processed into blank cakes, and after polishing, the color difference measuring instrument (model: 6801) produced by Germany BYK-GARDNER GMBH company is used. Carry out gold degree test, obtain three kinds of alloy gold degree test comparison data, test result is shown in Table 3.

[0044] table 3:

[0045]

[0046] It can be seen from Table 3 that the color difference dE between HSn72-1-1 alloy and gold * =25.65, while the colo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com