Apparatus and method for liquid metals treatment

一种液体金属、熔体的技术,应用在金属加工设备、铸造设备、照明和加热设备等方向,能够解决液体金属处理有效性和效率折衷等问题,达到促进动力学条件、提高均匀性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

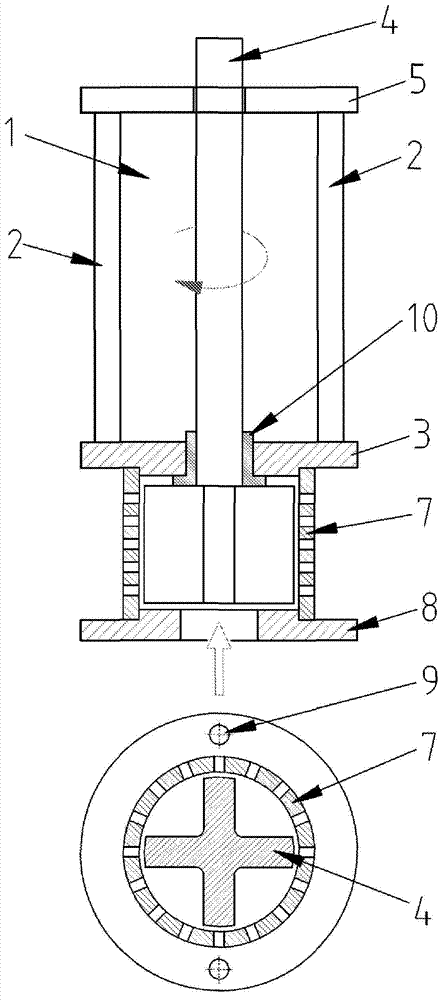

[0126] The AZ91D magnesium alloy was melted at 680°C and then passed with reference image 3 Methods and apparatus for performing intense melt shear with conditioning at temperatures below liquidus. The conditioned AZ91D semi-solid slurry was fed to a standard cold chamber high pressure die casting machine to cast tensile test specimens. Figure 8 The uniform and fine microstructure of AZ91D samples prepared by semi-solid processing according to the present invention is shown.

Embodiment 2

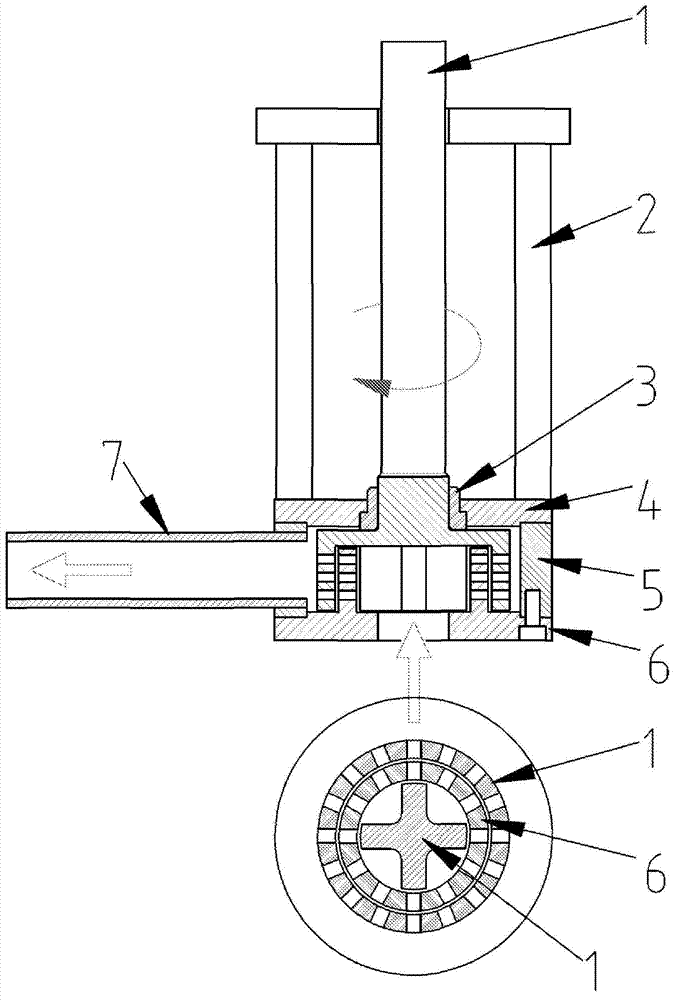

[0128] LM24 cast aluminum alloy and AA7075 wrought aluminum alloy were melted at 700°C and then treated with the Image 6 The method and equipment implemented in Degassing. The gas content in liquid aluminum alloys was evaluated by the reduced pressure test (RPT) using the density index as an indication of the gas content in the melt (the higher the density index, the higher the gas content). For recycled LM24 alloy, in use Image 6 The density index decreased from 13.60% to 2.66% after 1 minute of degassing with the method and apparatus of the embodiment shown in . For fresh AA7075 alloy, the density index decreases from 9.32% to 0.69%.

Embodiment 3

[0130] at 630°C according to the invention according to reference Image 6 Method and Apparatus for Fabrication of MMCs Based on AZ91D Magnesium Alloy Using Strong Melt Shearing. The AZ91D magnesium alloy was melted at 650°C. refer to Image 6 , preheated silicon carbide particles were added to the melt via the feed tube (26) by means of strong melt shear, and the melt and silicon carbide particles were then strongly sheared for an additional 5 minutes. The prepared Mg / SiC slurry was then fed to a standard cold chamber high pressure die casting machine to cast the MMC samples. Figure 9 Shows a fine and uniform structure and well-distributed silicon carbide particles in the Mg matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com