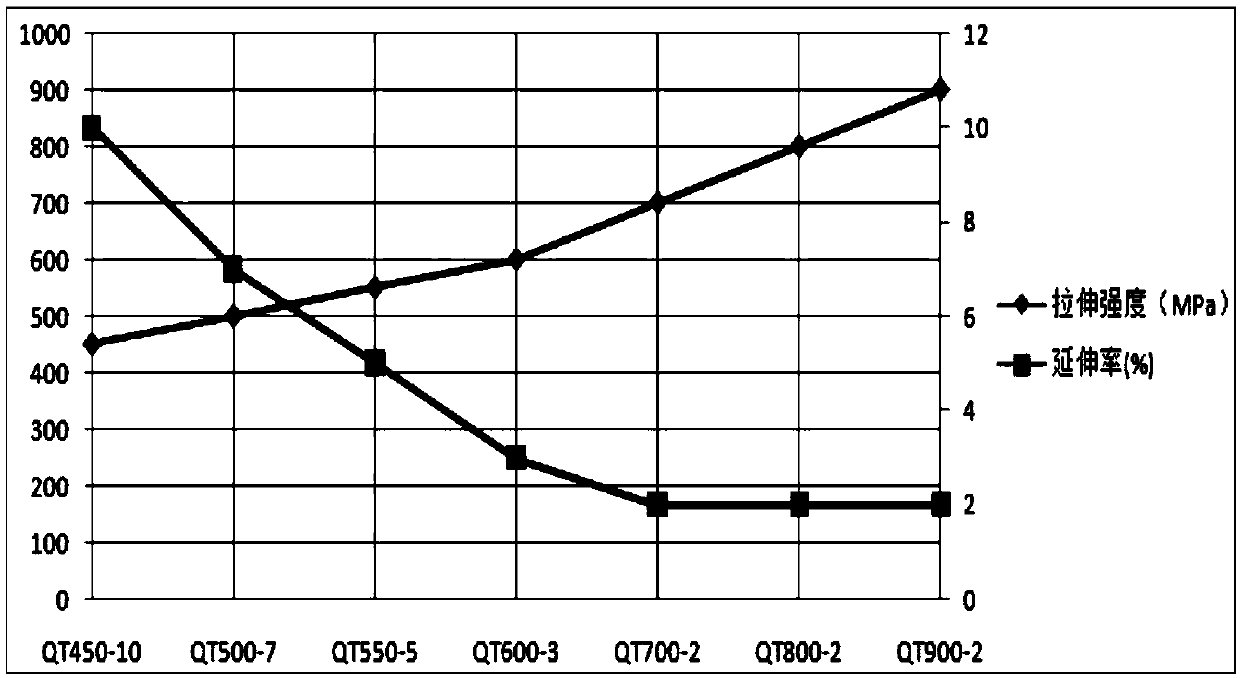

Production method of nodular cast iron with high strength and high elongation

A nodular cast iron and production method technology, applied in the field of casting technology, can solve problems such as complex process, long production cycle, cold shut, and pore defects, and achieve the effects of widening the application field, simple casting process, and obvious reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1: Production of 80T mine dump truck balance suspension bracket

[0054] The weight of the part is 74Kg, the basic wall thickness is 25mm, and the external dimension is 800*600*300mm.

[0055] The process used is:

[0056] 1. Use Linzhou Q10 low-sulfur and low-titanium pig iron, ordinary carbon steel and self-produced returned iron as the main charge, and use a 3-ton intermediate frequency furnace for smelting. The mass ratio of the main charge is: pig iron 602Kg, accounting for 20%, scrap steel 1808Kg, The proportion is 60%, the returned iron is 598Kg, accounting for 20%, and the error is less than ±0.8%. Add 21.3Kg of 75 ferrosilicon (containing 75% of silicon), 0.71% of the mass of the main charge; add 5.1Kg of 65 high-carbon ferromanganese (containing 65% of manganese), 0.17% of the mass of the main charge; add 5.7Kg of electrolytic copper (low lead, purity 99.99%), 0.19% of the mass of the main charge; add 69.9Kg of graphite type recarburizer, 2.33% of th...

Embodiment 2

[0065] Embodiment 2 Production of 50T muck truck balance suspension bracket

[0066] The weight of the part is 60Kg, the basic wall thickness is 25mm, and the external dimension is 750*550*290mm.

[0067] 1. Using Linzhou Q10 low-sulfur and low-titanium pig iron, ordinary carbon steel and self-produced returned iron as the main charge, using a 3-ton intermediate frequency furnace for smelting, the main charge is: pig iron 600Kg, scrap steel 1802Kg, and returned iron 602Kg. Add 21.3Kg of 75 ferrosilicon, 5.1Kg of 65 high carbon ferromanganese, 5.7Kg of electrolytic copper, and 69.9Kg of graphite recarburizer. After smelting, raw molten iron with components C 3.82%, Si 1.64%, Mn 0.27%, Cu 0.24%, and S≤0.03% is obtained.

[0068] 2. Weigh 5.38Kg of 2-6 nodulizer and 1.34Kg of 3-7 nodulizer and mix to prepare special nodulizer. Put the above-mentioned nodulizer into the nodulizer bag, and the proportion is 1.12% based on 600Kg of iron out of each pouring bag;

[0069] 3. Accord...

Embodiment 380

[0076] Example 3 80T Mine Dump Truck Air Chamber Bracket

[0077] The weight of the part is 27Kg, the basic wall thickness is 20mm, and the outer dimension is 300*250*200mm.

[0078] 1. Use Linzhou Q10 low-sulfur and low-titanium pig iron, ordinary carbon steel and self-produced recycled iron as the main charge, and use a 3-ton intermediate frequency furnace for smelting. The main charge is 598Kg of pig iron, 1796Kg of scrap steel, 604Kg of returned furnace iron, and then add 75% of ferrosilicon 21.3 Kg, 5.1Kg of 65 high-carbon ferromanganese, 5.7Kg of electrolytic copper, and 69.9Kg of graphite-type recarburizer. After smelting, raw molten iron with components C 3.79%, Si 1.69%, Mn 0.27%, Cu 0.21%, and S≤0.03% is obtained.

[0079] 2. Weigh 5.32Kg of 2-6 nodulizer and 1.33Kg of 3-7 nodulizer and mix to prepare special nodulizer. Put the above-mentioned spheroidizing agent into the spheroidizing bag;

[0080] 3. According to Figure 7 Packed in the same way, add 2.52Kg of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com