Method for preparing high-strength high-conductivity copper alloy plate and strip

A copper alloy plate, high conductivity technology, applied in the field of copper alloy, can solve the problems of poor fatigue resistance, poor plasticity, low strength, etc., and achieve the effects of eliminating work hardening, increasing strength, and improving casting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preparation method of TKB copper alloy strip includes the following steps:

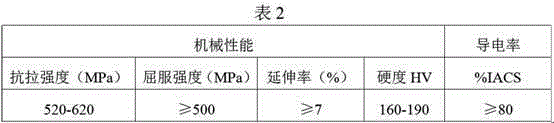

[0021] (1) According to the effective volume of the power frequency cored induction furnace, the mass ratio is copper: chromium: silver: iron: silicon: titanium = 99.23: 0.55: 0.08: 0.06: 0.03: 0.05 for batching; the copper and iron The copper master alloy and silver are put into the furnace body of the power frequency cored induction furnace, and the surface of the melt is covered with a 50-100mm thick mixture of borax and glass powder (the mass ratio of borax to glass powder is 2:1). Melt at 1280-1300°C (1280°C, 1290°C, 1300°C). After smelting, add silicon and chromium to the furnace and raise the temperature to 1350°C for smelting. After smelting, add the titanium-copper master alloy to the furnace and keep it warm for 30 minutes. , Then lower the temperature to 1260-1280℃ (1260℃, 1270℃, 1280℃);

[0022] (2) The temperature of the above copper water is 1260℃-1280℃ (1280℃, 1270℃, 1260℃), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com