Method for casting piston blank with inner cooling path by liquid state extruding casting process

A squeeze casting and process technology, which is used in the field of piston blank manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

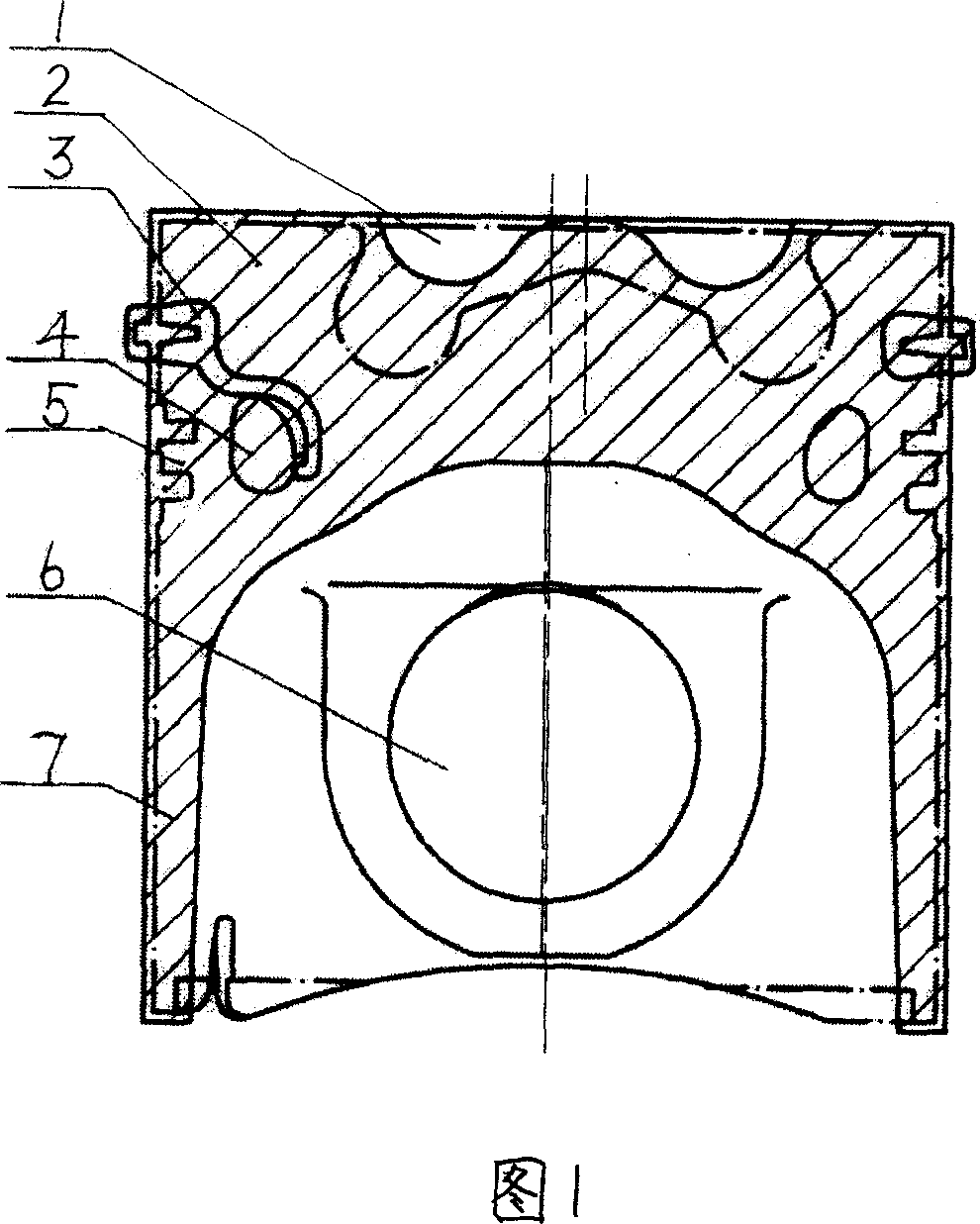

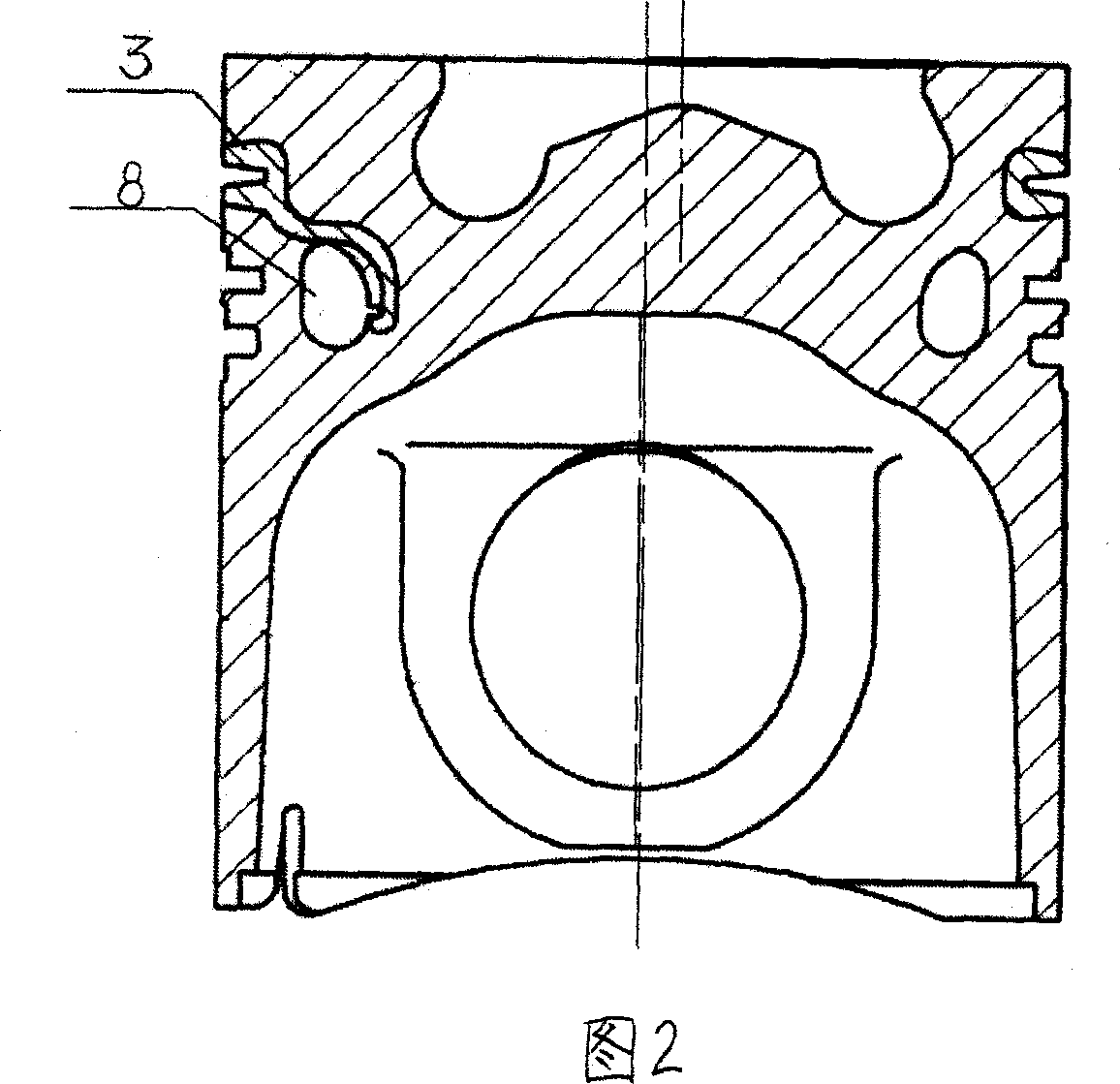

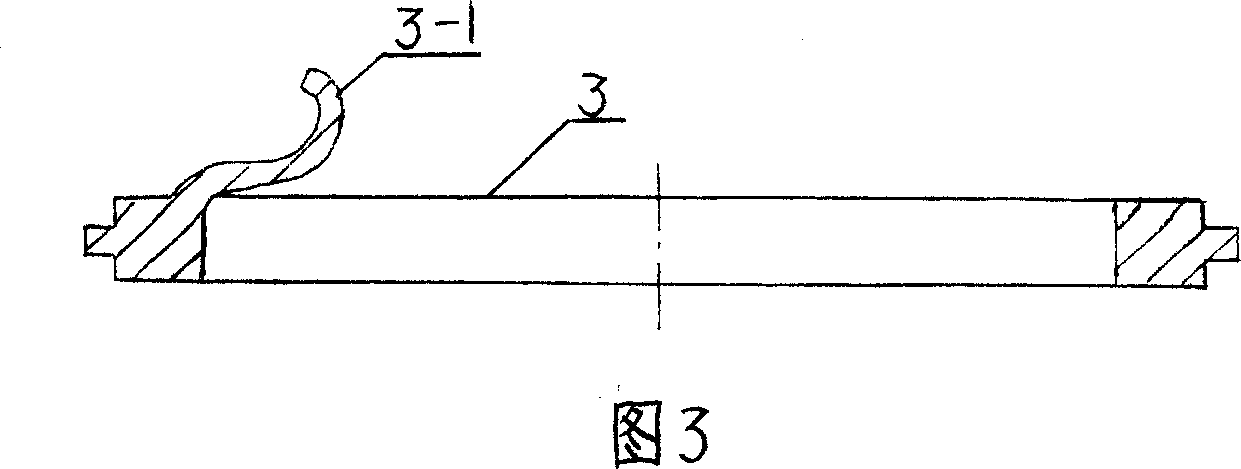

[0019] Further illustrate the present invention below in conjunction with accompanying drawing.

[0020] Described dissolvable core (4) is made by following method:

[0021] a. Grind table salt and corundum until they pass through a 80-120 mesh sieve, then heat to 450-550°C to remove water and other volatile impurities contained therein;

[0022] b. According to the ratio of 20-40 parts by weight of corundum and 60-80 parts by weight of table salt, mix them evenly;

[0023] c. Put the uniformly mixed raw materials into the mold and extrude them;

[0024] d. Carry out turning processing on the shape of the formed soluble core;

[0025] e. Send the processed soluble core into the roasting furnace for firing, and then take it out.

[0026] Through the above method, a soluble core with salt as a binder and corundum particles as a matrix can be prepared. After the piston blank is made, the oil inlet and outlet holes connected to the inner cavity of the piston are drilled at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com