Hafnium-containing high-tungsten-nickel-based isometric crystal alloy and application thereof

An equiaxed crystal, high tungsten technology, applied in blade support elements, engine elements, machines/engines, etc., can solve the problem that the temperature bearing capacity of the blade cannot meet the requirements, and achieves good thermal stability, high temperature oxidation resistance and resistance. The effect of good hot corrosion performance and long-lasting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The 500Kg vacuum induction furnace made in Germany is used to smelt the experimental master alloy. The smelting crucible is alumina crucible. The temperature measurement system is W-Re galvanic couple and JH-5 infrared photoconductive temperature / vacuum tester. The temperature measurement protection sleeve is Coated with ZrO 2 (CeO stabilized) and Mo-Al of BN 2 o 3 Metal-ceramic tube, the vacuum degree should be kept ≤10 -1 Pa order of magnitude. The operation process is as follows: put carbon, nickel-boron intermediate alloy, chromium, tungsten, niobium, hafnium, cobalt, zirconium and other alloy elements into the crucible; vacuumize the crucible to remove the adhesion Gas, when the vacuum reaches 10 -3 When a, increase the power to melt the alloy; ensure sufficient carbon-oxygen reaction at the initial stage of the material, and then refine at high temperature after melting to ensure uniform alloy composition. Refining at 1600°C for 5-7 minutes, cooling down after...

Embodiment 2

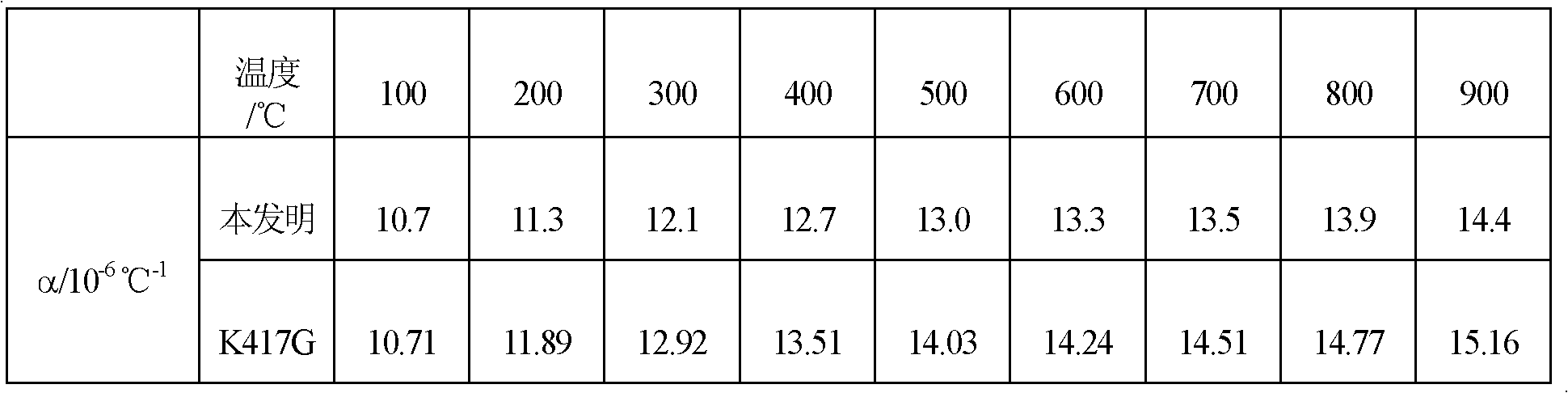

[0038] The present invention mainly adds more aluminum and titanium elements (Al+Ti<8wt.%) to form the gamma ' phase of high volume fraction to improve its intensity; Keep the content of chromium greater than 4.5wt.% and the ratio of Al / Ti greater than 2.5:1 can make the alloy reach the complete anti-oxidation level at high temperature; by adding niobium and hafnium, the number of γ′ phase can be further increased, the lattice mismatch degree of γ-γ′ can be improved, and the strengthening effect of γ′ phase can be enhanced. Form γ″ phase to enhance its mechanical properties at room temperature and medium temperature; add a certain amount of carbon, on the one hand, to strengthen the grain boundary, on the other hand, form more carbides with hafnium, niobium, chromium, etc. to strengthen the alloy; tungsten, cobalt and other alloys Elements mainly play an important role in solid solution strengthening alloys. The content of W+Hf+Nb is an important parameter to increase the creep...

Embodiment 3

[0046] The difference from Example 2 is that the alloy composition of this example is shown in Table 6, and the alloy durability performance corresponding to the alloy is shown in Table 7:

[0047] Table 6 Alloy element composition (wt.%)

[0048] C

Cr

co

Nb

Al

W

Ti

f

B

Zr

Ce

La

Ni

0.14

4.6

6.0

2.1

6.2

16.5

0.7

0.7

0.005

0.03

0.02

0.005

margin

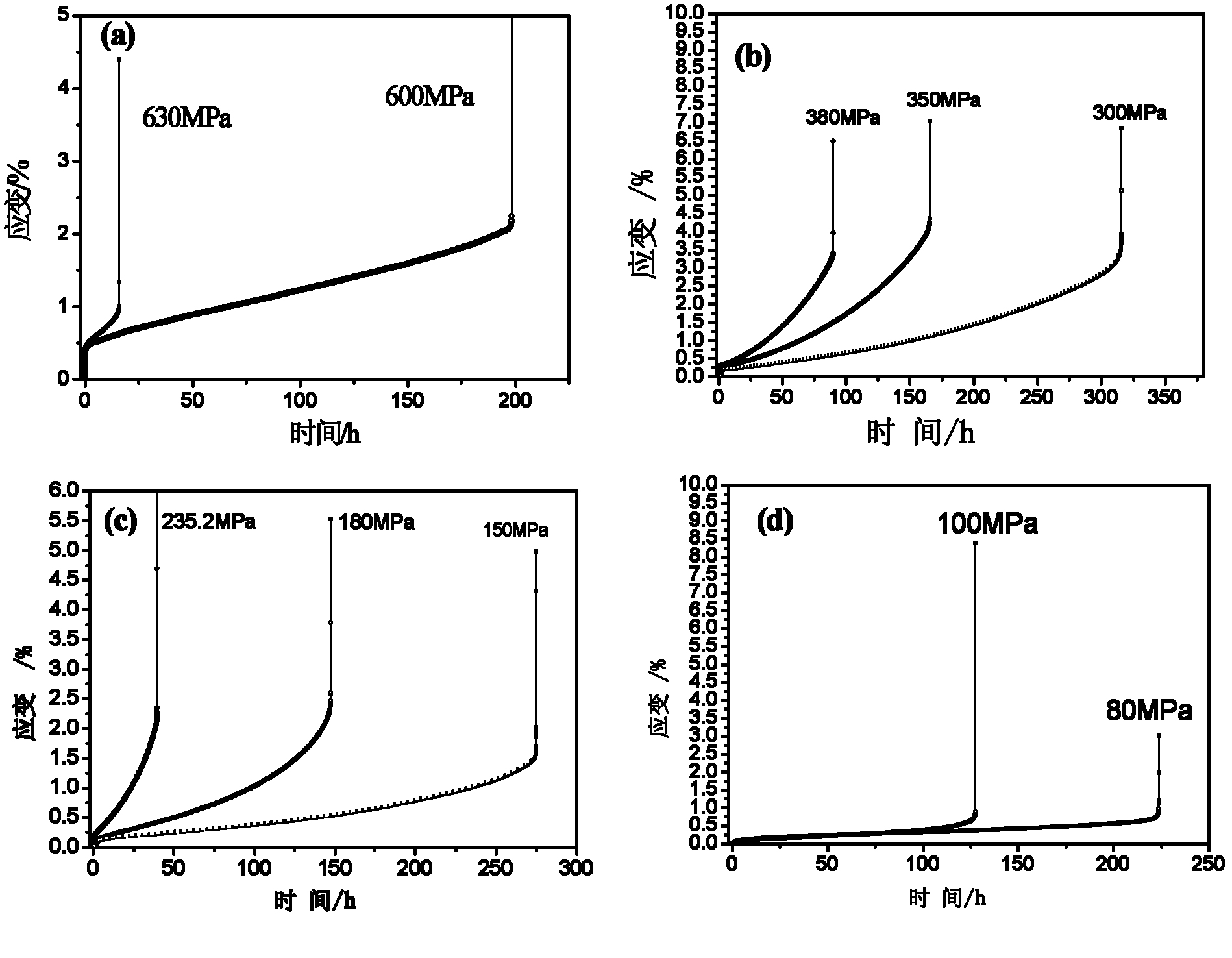

[0049] Table 7 Typical Temperature Durability of Alloys

[0050]

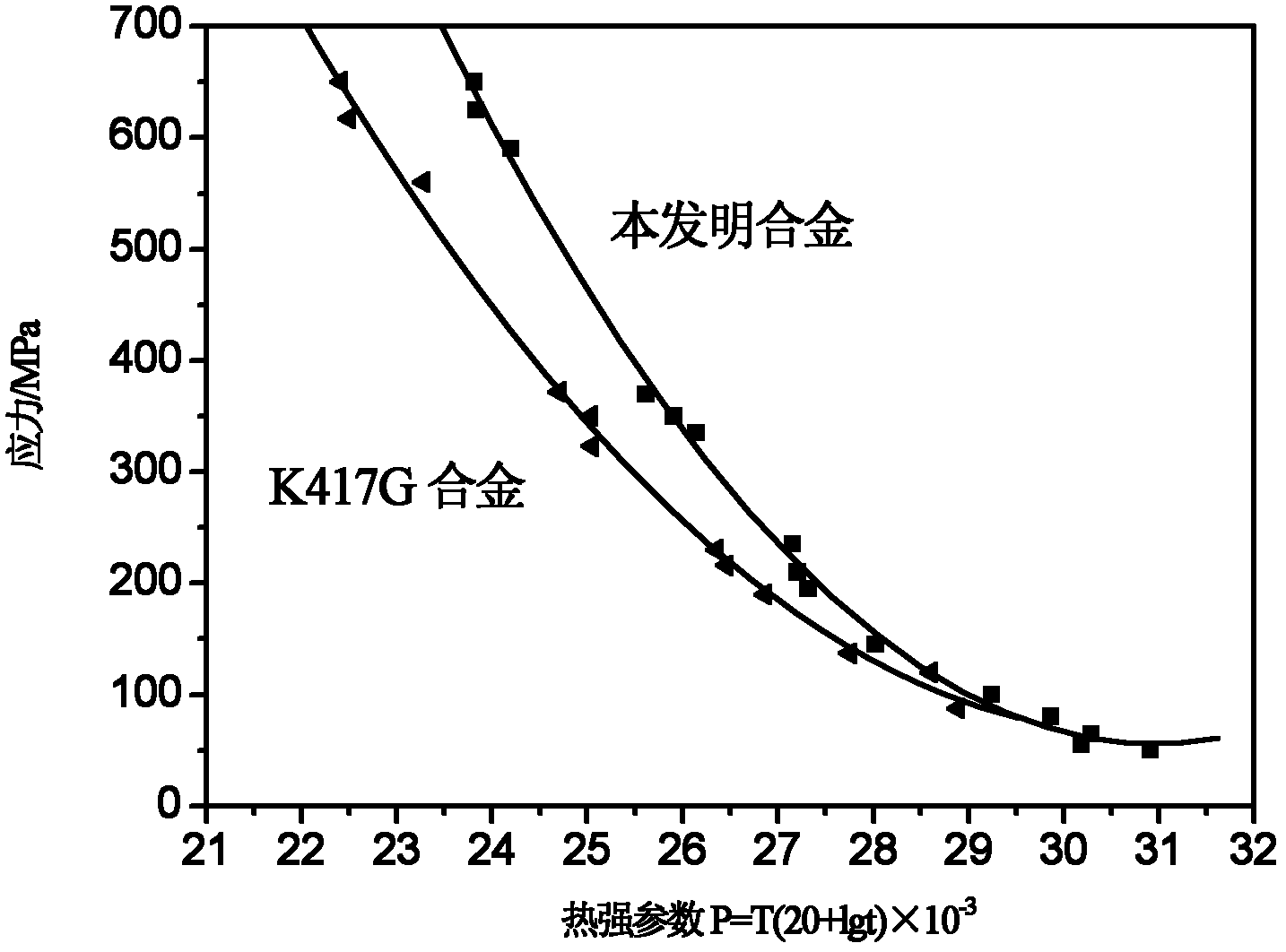

[0051] Such as figure 1 As shown, it can be seen from the composite curves of the thermal strength parameters of the alloy of the present invention and the comparison alloy that the durable stress of the alloy of the present invention gradually decreases with the increase of the thermal strength parameter; especially after the thermal strength parameter P=26, the persistent stress The drop is huge. The compariso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com