Metallic materials for rheocasting or thixoforming and method for manufacturing the same

A metal raw material, thixoforming technology, applied in rheological casting or thixoforming metal raw material and its manufacturing field, can solve the problems of reducing cooling rate, increasing process time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

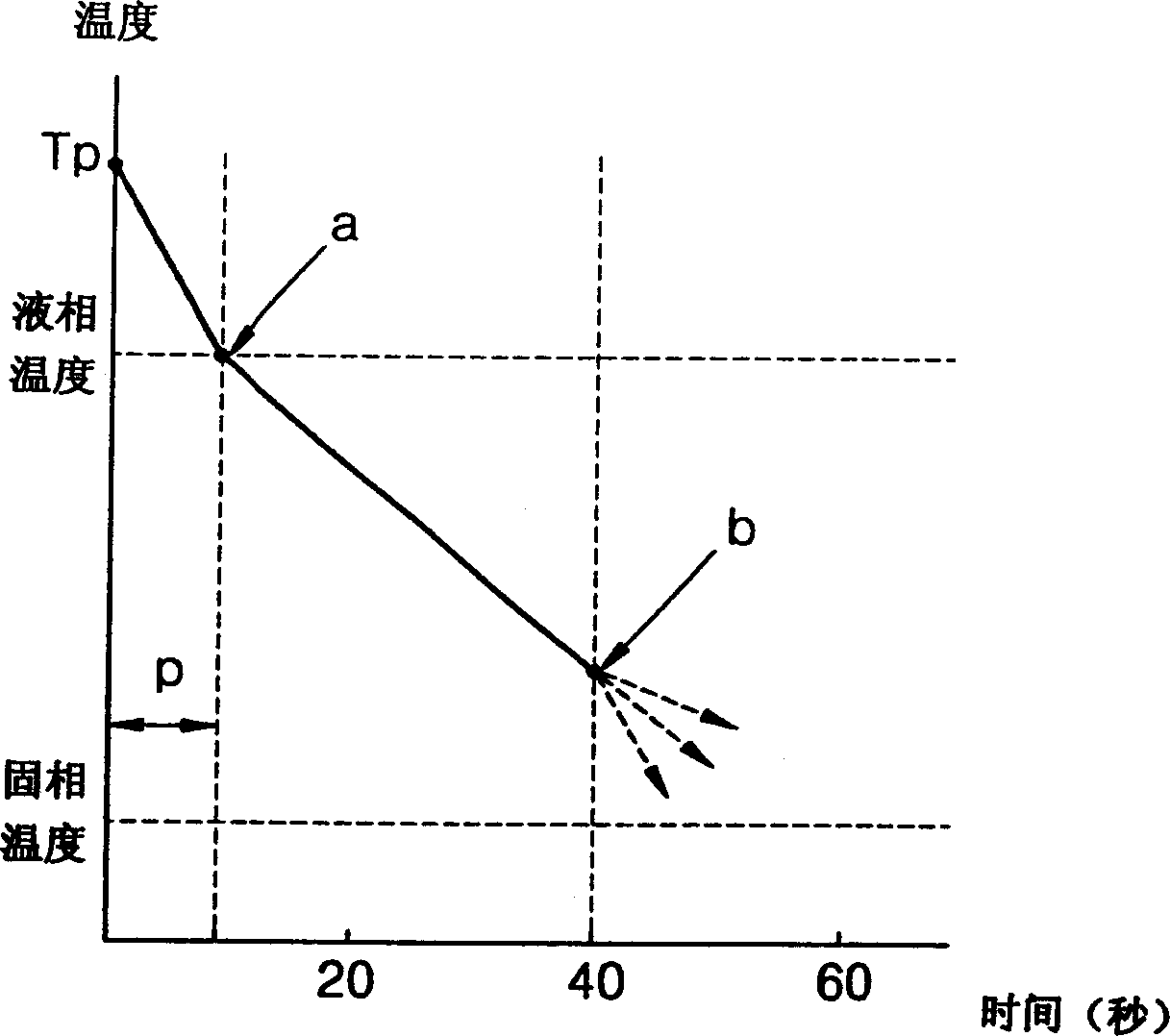

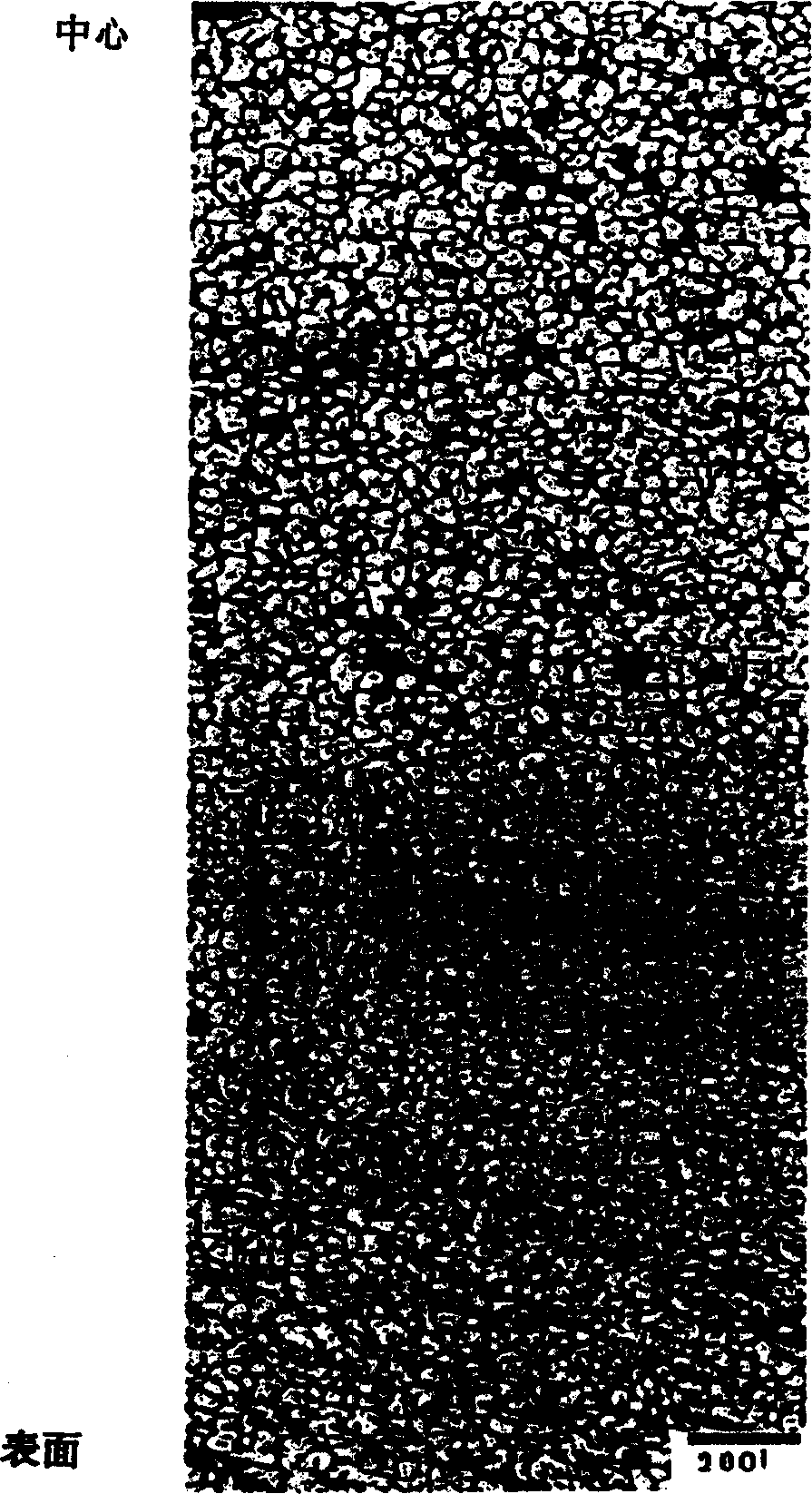

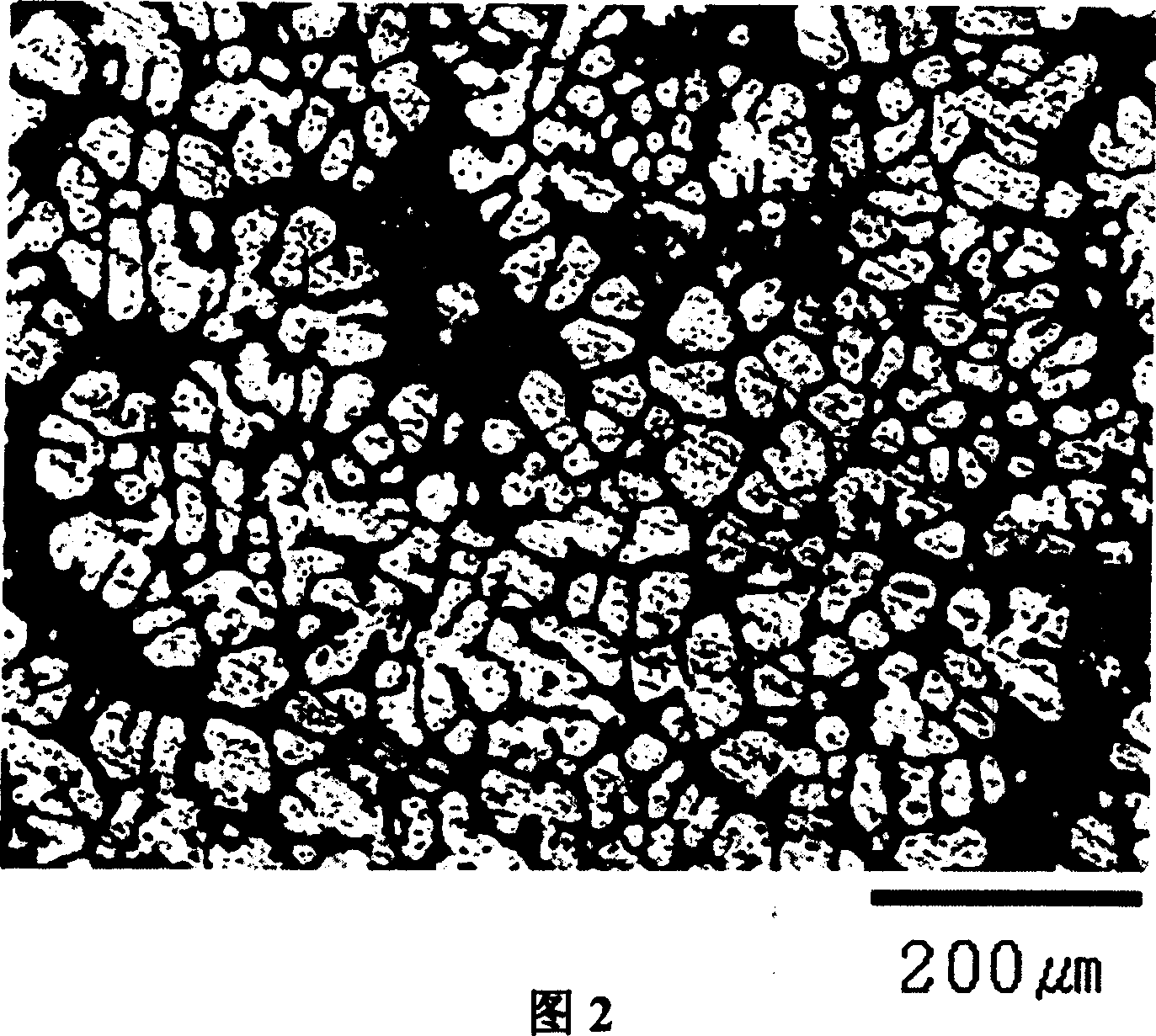

[0032]In a method of manufacturing metal feedstock for rheocasting or thixoforming according to the present invention, a molten metal in a vessel has the same temperature. Moreover, since the temperature of the entire vessel containing the molten metal is the same, including the center, inner walls, upper and lower regions of the vessel, latent heat caused by solidification behavior in specific regions at the beginning of cooling will not be affected. It will be produced so that the molten metal can be cooled rapidly in a short time. Therefore, the density of crystal nuclei in the molten metal will increase significantly, thereby forming micro, spherical particles.

[0033] Afterwards, the present invention will be described in detail.

[0034] According to the present invention, before the filling of a molten metal into a vessel is completed, an electromagnetic field is supplied to the vessel; that is, before, simultaneously with, or during filling of the molten metal into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com