Cast steel member detection method based on BIM technology

A detection method and technology for steel castings, applied in measuring devices, instruments, optical devices, etc., can solve the problems of slow efficiency, low precision of steel casting size detection, unclear expression of detection results, etc., to improve measurement efficiency, Avoid waste of construction resources and improve the overall level of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

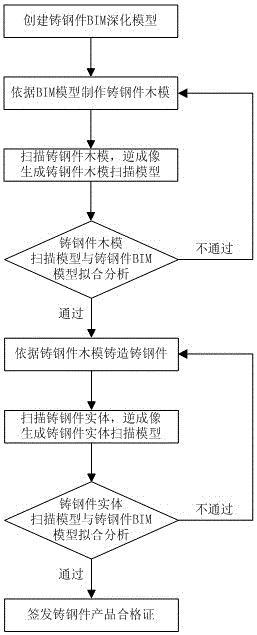

[0027] Such as figure 1 Shown, the present invention will be further described below in conjunction with accompanying drawing.

[0028] Step 1: Create a BIM deepening model of steel castings, the model depth reaches LOD300, and output the detailed design drawings of steel castings through the BIM model for use by the processing plant.

[0029] Step 2: Make wooden molds for steel castings based on the BIM model of steel castings and the detailed design drawings.

[0030] Step 3: Use a handheld 3D laser scanner to scan the wooden mold model. The handheld 3D laser scanner can scan the real object and then inversely image it to generate a spatial 3D surface model with an accuracy of 0.1mm, that is, the scanned model of the wooden mold of the cast steel.

[0031] Step 4: Fit and analyze the scanned inverse imaging model of the wooden mold of the steel casting and the BIM model of the steel casting. The system performs calculation and analysis on the spatial three-dimensional mask ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com