Method for preparing graphene fiber through graphene film twisting forming method

A graphene fiber and graphene film technology, applied in the chemical characteristics of fibers, textiles, papermaking, yarns, etc., can solve the problems of high drying energy consumption and complicated processes, and achieve good flexibility, easy operation and tight integration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

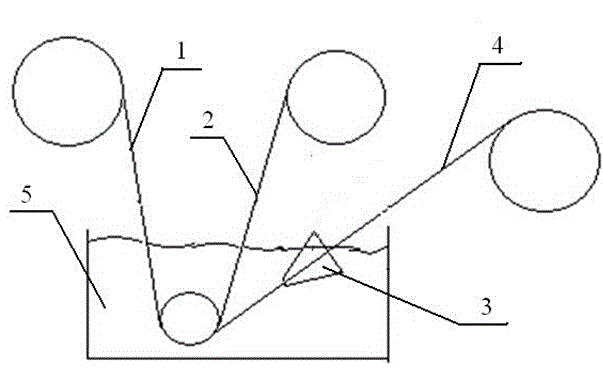

Image

Examples

Embodiment 1

[0020] Copper foil-loaded graphene film roll 1 is prepared on the surface of copper foil with a width of 50 cm by CVD method, and the copper foil roll is introduced into a pool 5 with a temperature of 90 ° C. The graphene film will be separated from the copper foil, and the Copper foil is rewound at a speed of 0.1 m / min. 2. The graphene film is gathered and twisted. 3. Twisted into a graphene fiber with a twist of 1000 twists / 10 cm and a diameter of 70 μm. 4. The graphene sheet is simultaneously increased by twisting. The combination fastness solves the problem that the strength of graphene fibers prepared by other methods is not greatly improved. At the same time, it is output to a winding forming device to directly make a twisted graphene fiber bobbin with a certain volume capacity.

Embodiment 2

[0022] Use CVD equipment to heat the copper foil to 1060 degrees to prepare copper foil-loaded graphene film coils on the surface of copper foil with a width of 100 cm, and introduce the copper foil coils into water at a temperature of 80 ° C. The foil is separated, and the copper foil is rewound at a speed of 0.01 m / min. The graphene film is twisted by a ring spinning gathering and twisting device into a wire with a twist of 2000 twists / 10 cm and a diameter of 120 μm. Twisting synchronously increases the bonding fastness of graphene sheets, which solves the problem that the strength of graphene fibers prepared by other methods is not greatly improved; at the same time, it is output to the winding forming device to directly make graphene fibers with a certain winding capacity and twist bobbin.

Embodiment 3

[0024] Prepare a copper foil-loaded graphene film coil on the surface of a copper foil with a width of 120 cm by vacuum heating the copper foil to 1060 degrees, and introduce the copper foil coil into water at a temperature of 90 ° C. Separation occurs, and the copper foil is rewound at a speed of 0.01 m / min. The graphene film is twisted by an air-jet spinning gathering and twisting device into a wire with a twist of 2000 twists / 10 cm and a diameter of 150 μm. Three wires are twisted together to form a wire of 210 μm line. Twisting synchronously increases the bonding fastness of graphene sheets, which solves the problem that the strength of graphene fibers prepared by other methods is not greatly improved; at the same time, it is output to the winding forming device to directly make graphene fibers with a certain winding capacity and twist bobbin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com