Method for preparing graphene fiber by casting method

A technology of graphene fiber and casting method, which is applied in the direction of fiber chemical characteristics, continuous winding spinning machine, textile and papermaking, etc., which can solve the problems of large drying energy consumption and complicated process, and achieve uniform structure and easy operation. Simple process and tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

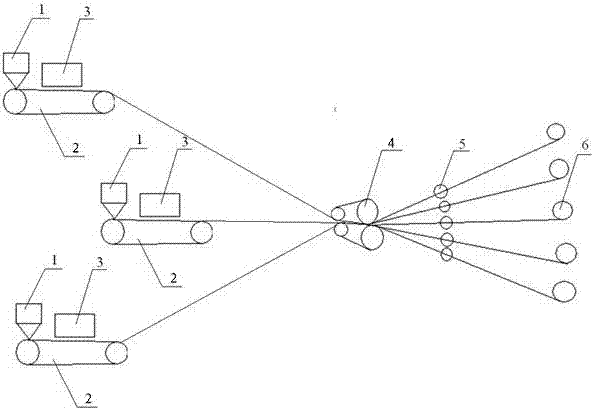

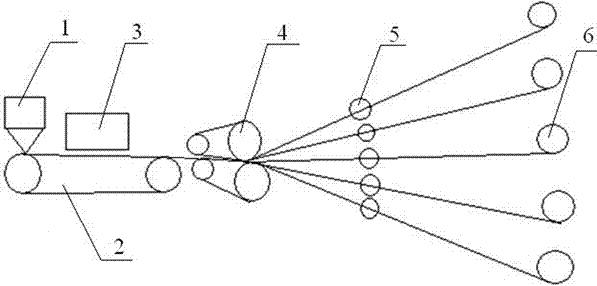

[0025] The invention relates to a device and method for casting graphene fibers and yarns, and belongs to the technical field of graphene oxide and graphene material preparation. The method is as follows: the mixed solution of 3 parts of worm-like expanded graphite, 100 parts of distilled water and 0.01 part of surfactant (sodium dodecylbenzenesulfonate) is passed through a liquid stirring pulverizer (emulsifier) with a rotation speed of 50,000 rpm. ) to obtain graphite oxide colloidal liquid, which was concentrated to obtain 25 mg·mL -1 Graphite oxide colloid liquid, the colloid is extruded by casting equipment 1 and cast onto the surface of grooved PTFE conductive belt 2, dried by dryer 3 at 60°C, and then the strip is clamped by stainless steel belt Continuous output, during which the 5-ton pressure roller 4 is compacted to obtain a graphene oxide strip with a thickness of 16 μm and a width of 0.5mm. 5. After spraying through the hole at the end of the nozzle to the corr...

Embodiment 2

[0027] The invention relates to a device and method for casting graphene fibers and yarns, and belongs to the technical field of graphene oxide and graphene material preparation. The method is as follows: the mixed solution of 1-3 parts of worm-like expanded graphite, 100 parts of distilled water and 0.2 parts of surfactant (betaine) is processed by a liquid stirring pulverizer (emulsifier) with a rotation speed of 10,000 rpm to obtain Graphite oxide colloidal solution, obtained after concentration 20 mg·mL -1 Graphite oxide colloid liquid, the colloid is extruded and cast onto the surface of the grooved PTFE conductive tape through the casting equipment, and dried at 80°C by the dryer, and then the strip is clamped and output by the stainless steel belt, during which it passes through 2 Tons of pressure rollers were compacted to obtain graphene oxide strips with a thickness of 50 μm and a width of 0.5 mm. The strip is twisted by spraying air through the fluid nozzle, and a...

Embodiment 3

[0029] The invention relates to a device and method for casting graphene fibers and yarns, and belongs to the technical field of graphene oxide and graphene material preparation. The method is as follows: the mixed solution of 1 part of worm-like expanded graphite, 100 parts of distilled water and 0.03 part of surfactant (dodecyltrimethylammonium chloride) is passed through a liquid stirring pulverizer with a rotating speed of 20,000 rpm ( emulsifying machine) to obtain graphite oxide colloidal liquid, which was concentrated to obtain 25mg·mL -1Graphite oxide colloid liquid, the colloid is extruded by casting equipment and cast onto the surface of the grooved PTFE conductive tape, dried by a dryer at 60-80°C, and then the strip is clamped and output by a stainless steel belt. After being compacted by a 1-ton pressure roller, a graphene oxide strip with a thickness of 16 μm and a width of 0.5 mm is obtained. The graphene oxide strip is twisted by jetting air through a fluid noz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com