A method for surface treatment of artificial tooth implant

A technology for surface treatment and implants, which is applied in dentistry, dental implants, dental restorations, etc., can solve the problems of high failure rate, poor stability, and low usage rate, and achieve the effect of good stability, convenient manufacture, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

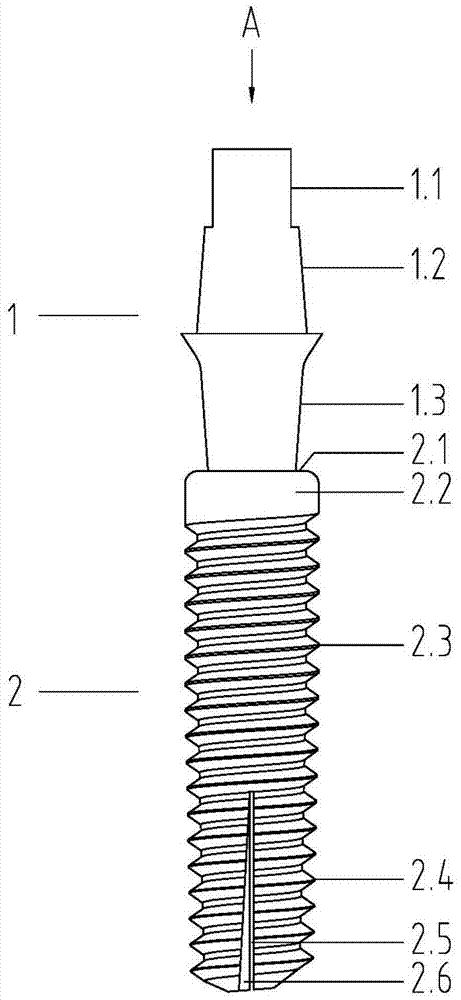

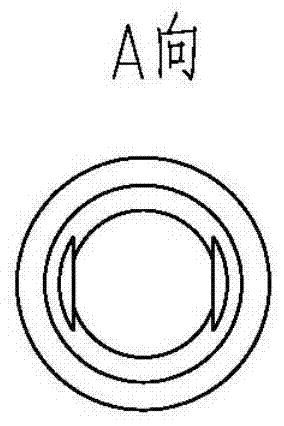

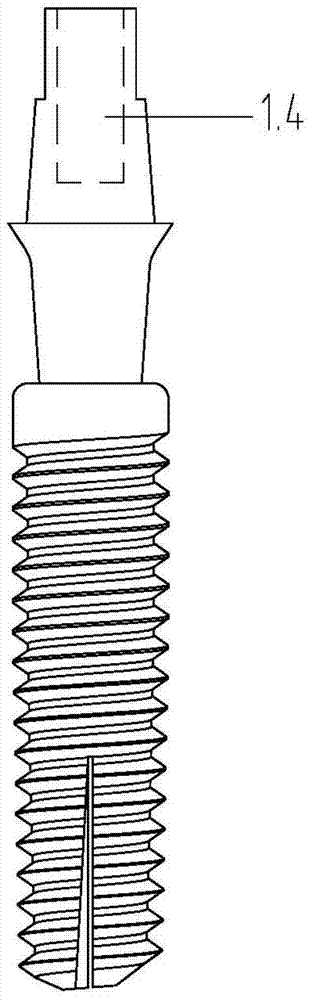

[0029] Such as Figure 1-3 As shown, the artificial tooth implant of the present invention adopts a one-stage structure, that is, the abutment 1 and the implant 2 are integrated, and the upper part of the abutment 1 is the abutment rod 1.2, which is responsible for connecting with the crown 3, and the abutment rod 1.2 is The upper part is small and the lower part is large, with a taper of 3° and a length of 6 mm. The connection between the abutment 1 and the crown 3 can be fixed by plug-in bonding or screw 4. When screw 4 is required, the abutment rod 1.2 Corresponding threaded holes 1.4 can be set at its top, such as image 3shown. Screw-in bayonets 1.1 are provided on both sides of the upper part of the abutment rod 1.2 to facilitate screwing the implant into the alveolar bone during planting. The lower part of the abutment 1 is a foundation pile 1.3, the foundati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com