Method for preparing graphene fibers by cutting graphite oxide film and heating

A technology of graphene fiber and graphite fiber, which is applied in the direction of fiber processing, fiber chemical characteristics, continuous winding spinning machine, etc., can solve the problems of complex process, large drying energy consumption, etc., and achieve uniform structure, good flexibility, Effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

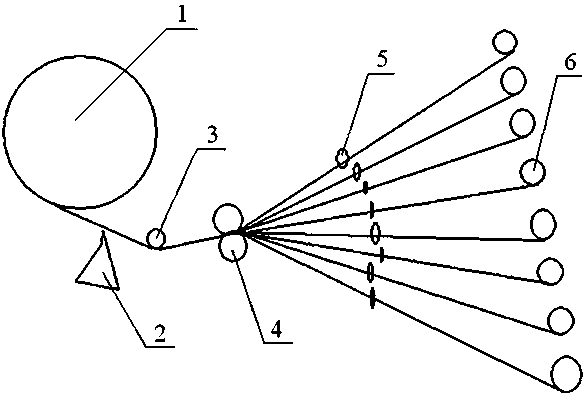

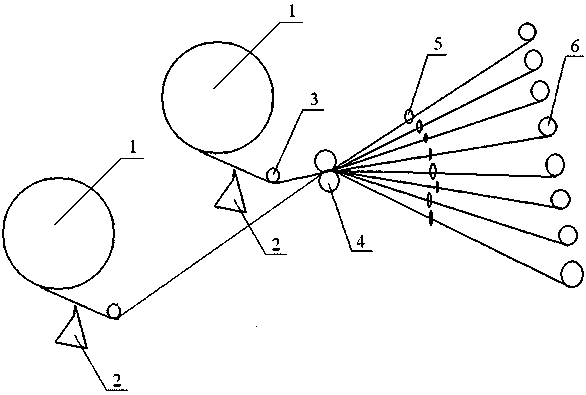

[0024] like figure 1 As shown, an ultra-thin graphite oxide film 1 with a diameter of 60 cm, a height of 10 cm, and a thickness of 30 μm (width 100 mm) is rolled. During the unwinding process, a layer of 5 μm is coated on the surface of the graphene film by the slit coating head 2. Thick titanium oxide nanotube aqueous emulsion (solid content 1%), then, through the guide roller 3, use the ultrasonic blade module film slitting machine 4 to cut into 200 pieces with a width of 0.5mm at a speed of 80m / s Continuous graphite oxide fiber; each one is a group of jetting air through the fluid nozzle for twisting, and then the high-frequency electromagnetic heating tube 5 heats each twisted graphene oxide yarn at a position 10 cm away from the nozzle, and the graphite oxide fiber transformed into graphene fibers. The above graphene fibers are output to the winding forming device, and directly made into a graphene fiber bobbin 6 with a certain winding capacity and twist, and the twistin...

Embodiment 2

[0026] Cut the ultra-thin graphite oxide film with a diameter of 60cm, a height of 10cm, and a thickness of 30μm (width 100mm) into 1000 pieces with a width of 0.1mm at a speed of 80m / s by an ultrasonic blade module film slitting machine. The continuous graphite oxide fiber; every 2 is a group of twisted by spraying air through the fluid nozzle, and then the high-frequency electromagnetic heating tube heats each twisted graphene oxide yarn at a position 10 cm away from the nozzle, and the graphite oxide fiber transformed into graphene fibers. The above graphene fibers are output to the winding forming device, and directly made into a graphene fiber bobbin with a certain volume capacity and twist. Twisting synchronously increases the bonding fastness of graphene sheets, which solves the problem of little improvement in the strength of graphene fibers prepared by other methods; the obtained graphene fibers have a diameter of 0.18 mm, twist, and a breaking strength greater than 2...

Embodiment 3

[0028] Cut the ultra-thin graphite oxide film with a diameter of 60cm, a height of 10cm, and a thickness of 30μm (width 100mm) into 6250 pieces with a mechanical rotary circular blade module film slitting machine at a speed of 80m / s. 0.015mm continuous graphite oxide fiber; each group of 10 is twisted by spraying air through the fluid nozzle, and then the high-frequency electromagnetic heating tube heats each twisted graphene oxide fiber at a position 10 cm away from the nozzle to oxidize The graphite fiber is converted into graphene fiber, and the above graphene fiber is output to the winding forming device, and directly made into a graphene fiber bobbin with a certain winding capacity and twist. Twisting synchronously increases the bonding fastness of graphene sheets, which solves the problem that the strength of graphene fibers prepared by other methods is not greatly improved; the obtained graphene fibers have a diameter of 0.15mm, twist, and a breaking strength greater tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com