High specific surface area of silicon oxide hybridized graphene aerogel and production method thereof

A technology of graphene airgel and high specific surface area, which is applied in the field of graphene airgel, can solve the problem of reducing specific surface area, and achieve the effect of high specific surface area, small silicon oxide particles, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

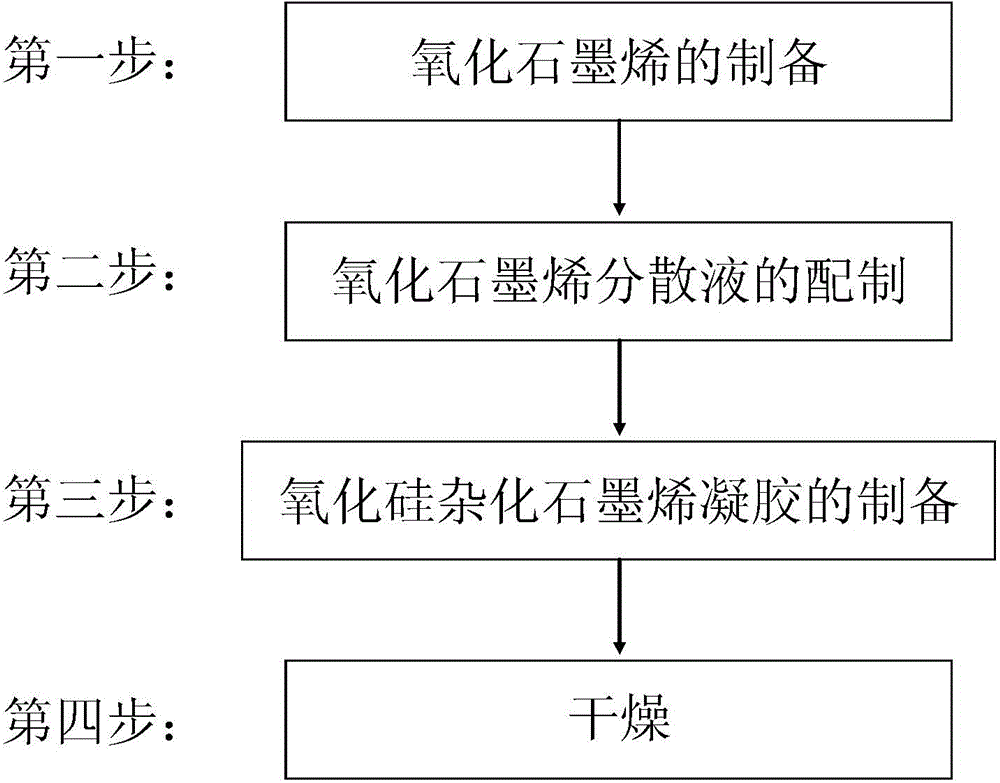

Method used

Image

Examples

Embodiment 1

[0034](1) 3g graphite powder is mixed with 18g potassium permanganate, 40ml concentrated phosphoric acid is mixed with 360ml concentrated sulfuric acid to obtain mixed acid, and gained mixed acid is added to gained graphite powder / In the potassium permanganate mixture, heat up to 50°C and react for 12 hours under a mechanical stirring condition of 300r / min, add the reaction mixture to 400ml of ice water containing 10ml of 30% hydrogen peroxide, and centrifuge at a speed of 2000r / min to obtain For the extract, dissolve the extract in 200ml of deionized water and centrifuge at a speed of 2000r / min for 1h, then dissolve the extract in 200ml of 30% hydrochloric acid and centrifuge for 1h at a speed of 2000r / min, and finally Dissolve the extract in 200ml of ethanol and centrifuge at a speed of 2000r / min for 1h, repeat the process of dissolving the extract in 200ml of ethanol and centrifuge at a speed of 2000r / min for 3 times, take the extract and dry it in vacuum at 50°C to obtain ...

Embodiment 2~36

[0046] The process parameters used in Examples 2 to 36 are shown in Table 1, and the process is the same as in Example 1, except that the type of siloxane, the ratio of deionized water to graphene oxide, the ratio of siloxane to oxidized The ratio of the number of graphene dispersions and other three parameters that have a greater impact on the performance of the high specific surface area silicon oxide hybrid graphene airgel, except for the process parameters written in the table, the rest of the process parameters are the same as in Example 1.

[0047] Table 1 Preparation process parameters and properties of high specific surface area silicon oxide hybrid graphene aerogels prepared in Examples 2-36

[0048]

[0049]

Embodiment 37

[0051] The difference between embodiment 37 and embodiment 1 lies in the fourth step, and the rest of the process parameters are the same as embodiment 1. The fourth step in Example 37 is: replace the hybrid graphene gel obtained in step (3) with 10 times the volume of deionized water and ethanol for 10 times, each replacement time is 6h, to obtain the silicon oxide after solvent replacement hybrid graphene gel, and then put the silica hybrid graphene gel after solvent replacement into CO 2 In the drying kettle of the supercritical drying device, then the supercritical CO 2 , replaced for 5 hours, and finally release the pressure at a rate of 100KPa / min, and cool down with the furnace to obtain silicon oxide hybrid graphene airgel with high specific surface area.

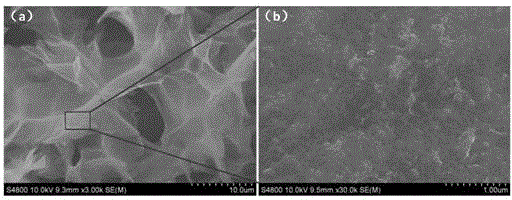

[0052] The SEM photo of the high specific surface area silicon oxide hybrid graphene airgel that embodiment 37 obtains is as follows Figure 4 As shown, the particles are silicon oxide particles, and the transluce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com