A kind of conductive sponge and its preparation method and application

A technology of conductive sponge and thermal initiator, applied in the field of pressure-sensitive adhesives, can solve the problems of stripping, large thickness, poor adhesion of pressure-sensitive adhesives, etc., and achieve the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

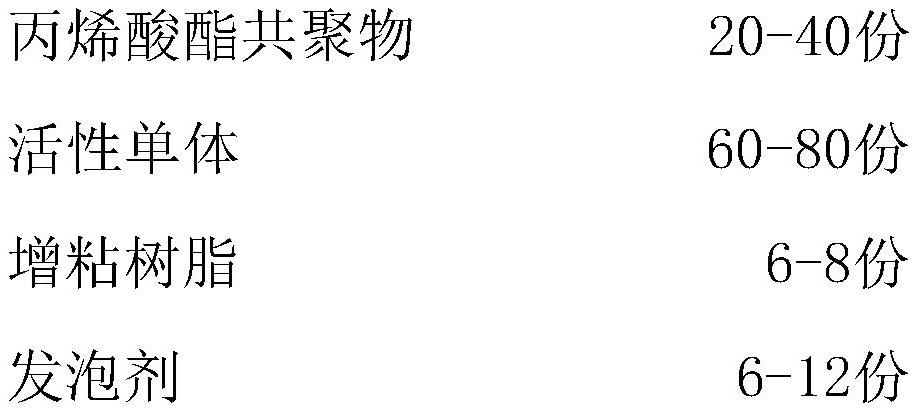

[0026] A conductive sponge, comprising the following raw materials in parts by weight:

[0027]

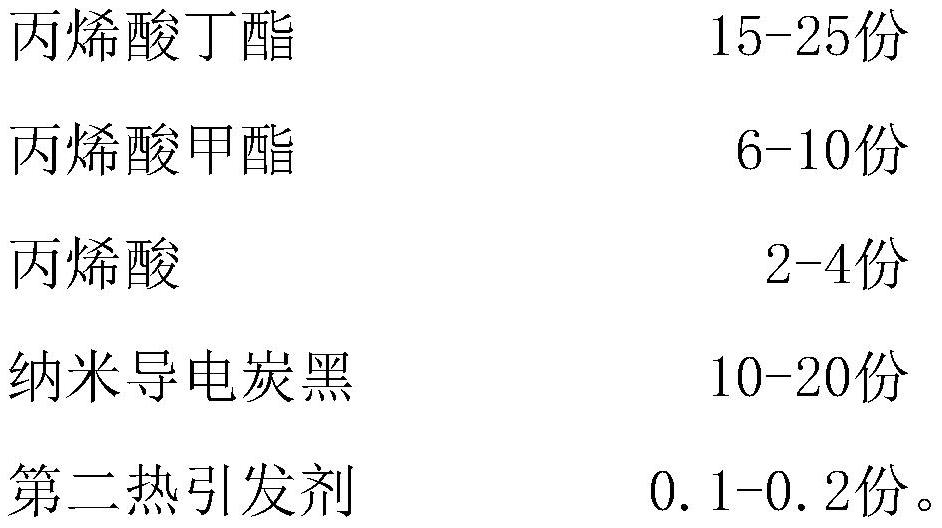

[0028] Described acrylate copolymer is made by following raw material:

[0029]

[0030] Wherein, the active monomer is composed of isooctyl acrylate, glycidyl methacrylate and butyl acrylate in a weight ratio of 15:25:60.

[0031] Wherein, the tackifying resin is terpene-phenolic resin.

[0032] Wherein, the blowing agent is sodium bicarbonate.

[0033] Wherein, the photoinitiator is composed of 907 photoinitiator, 1173 photoinitiator and TPO photoinitiator in a weight ratio of 1:1:1.

[0034] Wherein, the second thermal initiator is BPO; the first thermal initiator is composed of BPO and LPO in a weight ratio of 3:1.

[0035] Wherein, the particle diameter of the nano conductive carbon black is 25nm.

[0036] Wherein, the preparation method of described acrylate copolymer is: the butyl acrylate of 10 weight parts, the methyl acrylate of 4 weight parts, the nanometer co...

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 is:

[0040] The first thermal initiator is composed of BPO and LPO in a ratio of 1:1 by weight.

Embodiment 3

[0042] The difference between this embodiment and embodiment 1 is:

[0043] The first thermal initiator is BPO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com