Manufacturing method for molybdenum-niobium target blank

A manufacturing method and target blank technology, which are applied in the field of target sputtering, can solve the problem that the performance of molybdenum niobium target blank needs to be improved, and achieve the effect of improving process performance and mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

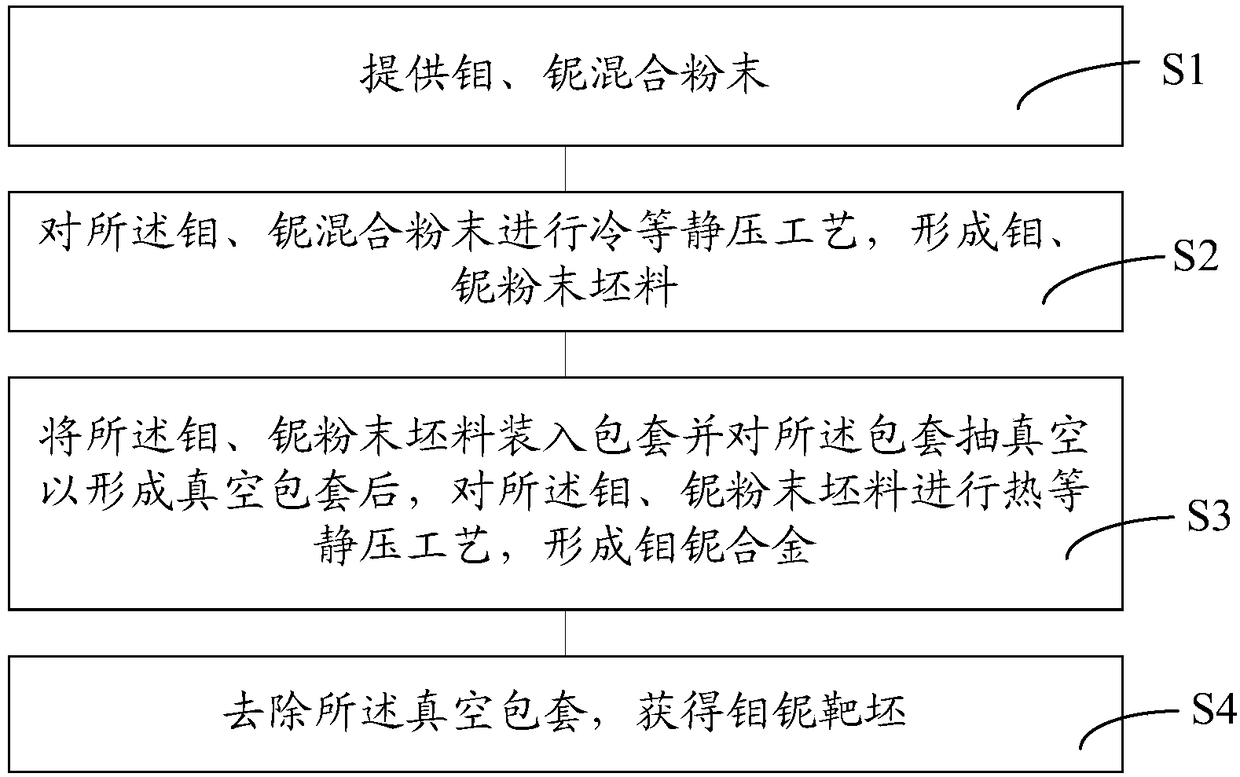

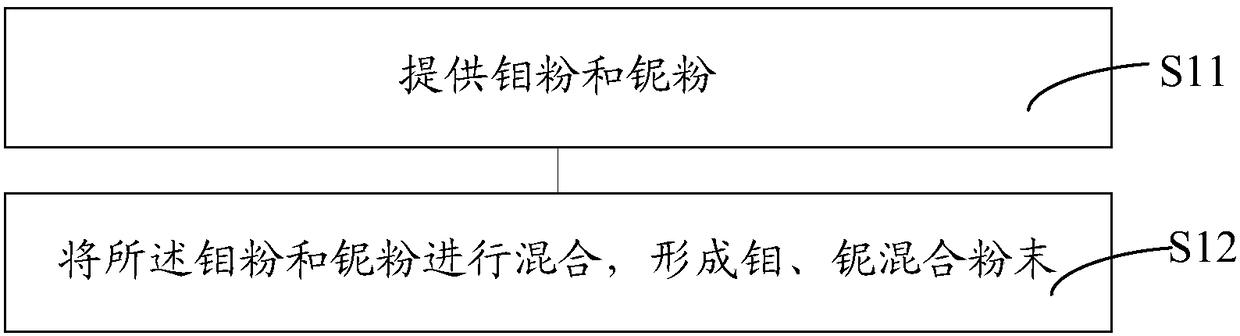

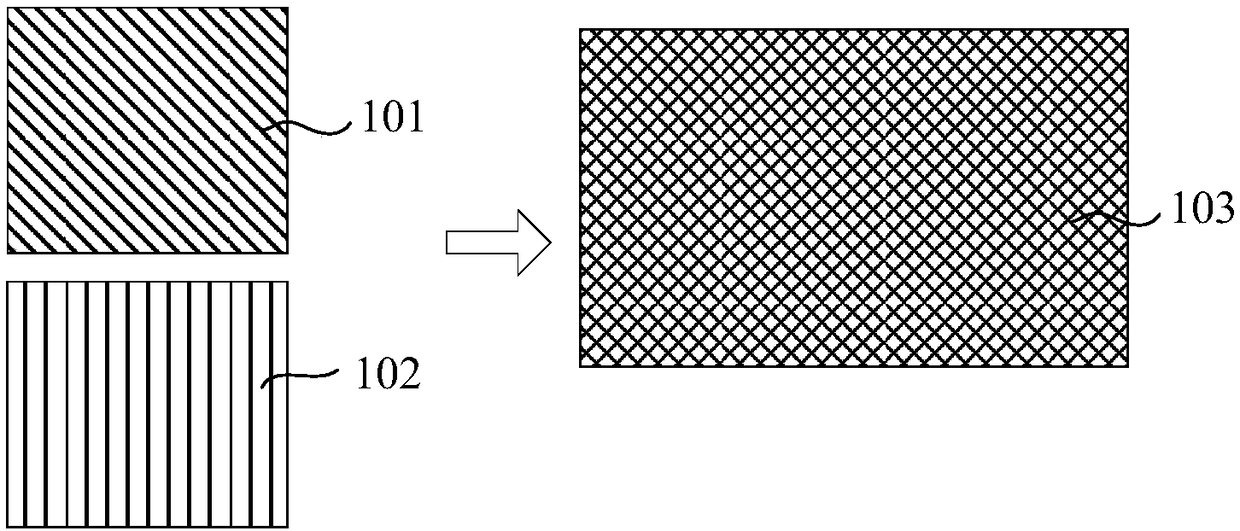

Method used

Image

Examples

Embodiment Construction

[0029] There are many manufacturing methods for the target blank. At present, the manufacturing method of the molybdenum-niobium target blank mainly adopts the method of hot pressing and sintering. Specifically, the prepared metal powder is packed in a specific mold, and then placed in a vacuum hot-press furnace. Under vacuum or inert gas conditions, using a press, the upper and lower pressure heads act on the mold. Pressurize until the pressure and temperature reach the set value, then keep it under the set pressure and temperature for a period of time, then cool down with the furnace, and then come out of the furnace to form the required target blank.

[0030] The method needs to design a matching mold according to the size of the molybdenum-niobium target blank. Correspondingly, the size of the molybdenum-niobium target blank is also limited by the size and strength of the mold, which is relatively expensive and easy to wear and tear. In addition, during the hot-press sinte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com