Manganese steel fork core steel rail split type frog

An assembly-type, steel rail technology, which is applied in the direction of tracks, switches, roads, etc., can solve the problems of traffic safety threats, non-welding repair and maintenance, etc., and achieve the effects of improving safety assurance, improving compactness, and ensuring casting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

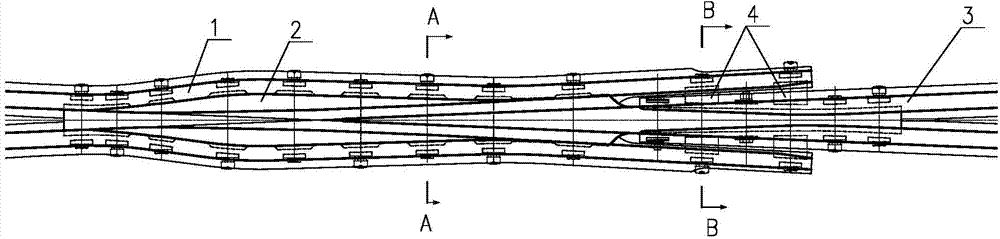

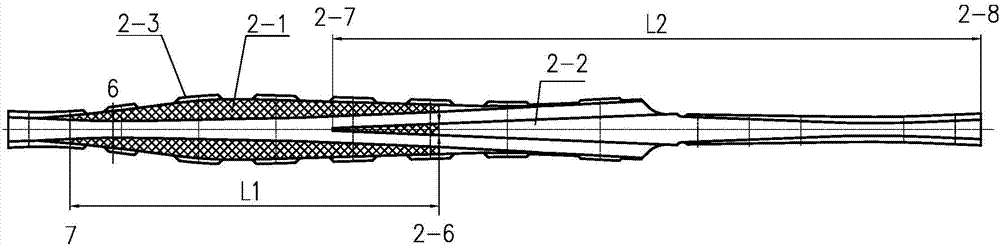

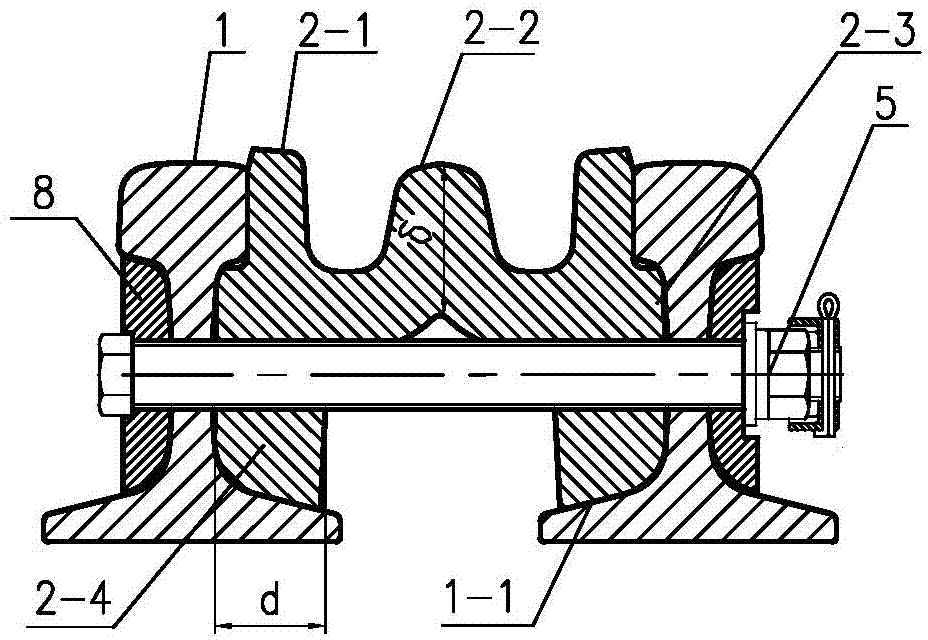

[0035] The present invention will be further described below in conjunction with the accompanying drawings. The basic innovation of the present invention is to use manganese steel (ZG100Mn13) fork center 2 as the core to assemble standard rail wing rail 1 and standard rail fork and heel rail 3 with high-strength bolt pairs 5, such as figure 1 shown. The shape design of the bottom surface of the fork center core rail is fitted on the upper surface 1-1 of the standard rail wing rail 1 rail bottom, and the vertical force on the center rail is directly transmitted to the standard rail wing rail bottom. The fork core matrix made of high manganese steel has good crack delay and can avoid the occurrence of brittle fracture; it can also use the mature online welding repair technology to repair the damaged wheel-rail action surface, greatly improving the service life of frogs, making The security of the equipment is highly guaranteed.

[0036] The main innovations of the manganese ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com