Anchored liner plate

An anchor plate and bearing plate technology, applied in structural elements, building components, building reinforcements, etc., can solve the problems of large volume, high material consumption and high production cost, achieve structural optimization, reduce the number of steel bars cut, and facilitate irrigation dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

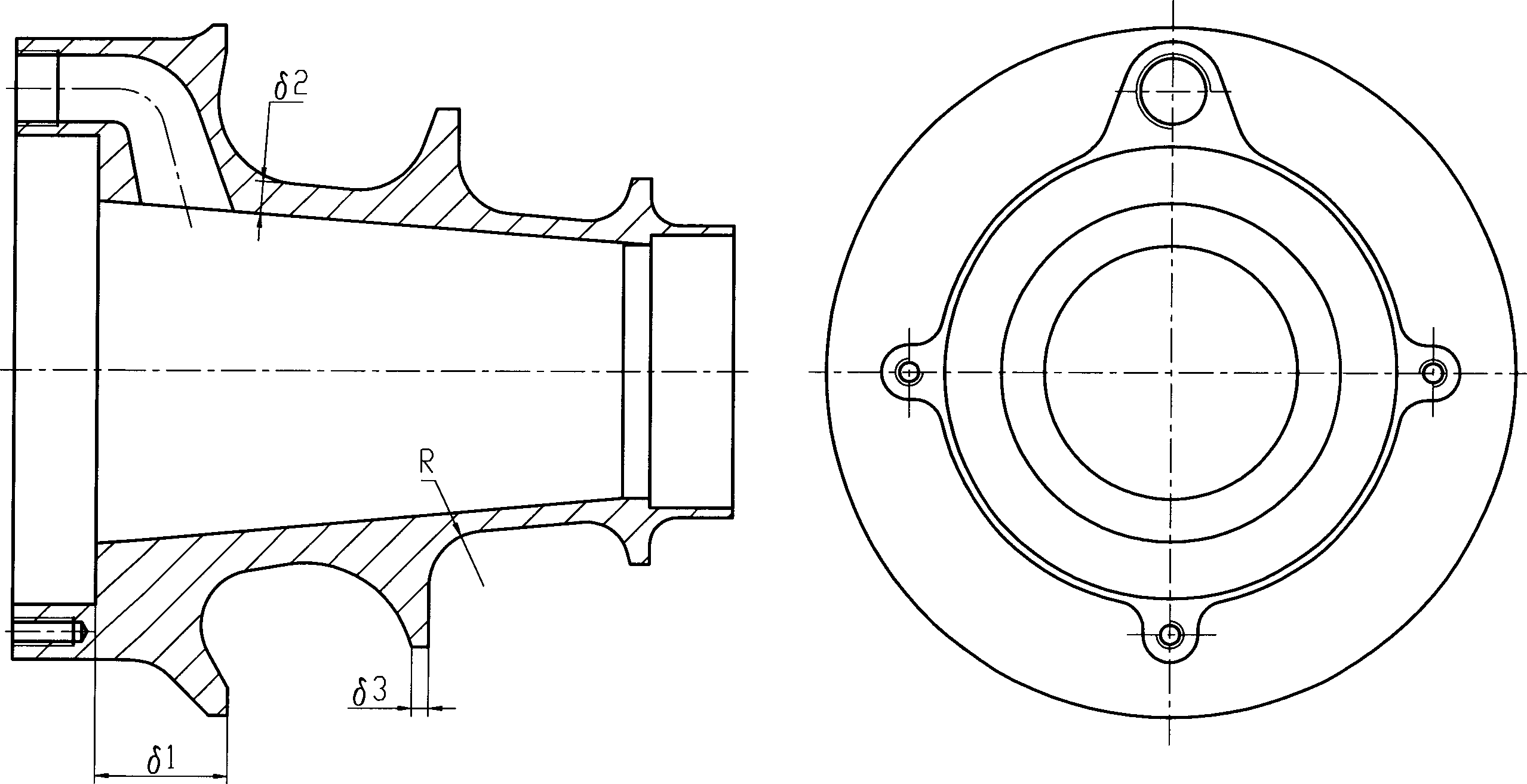

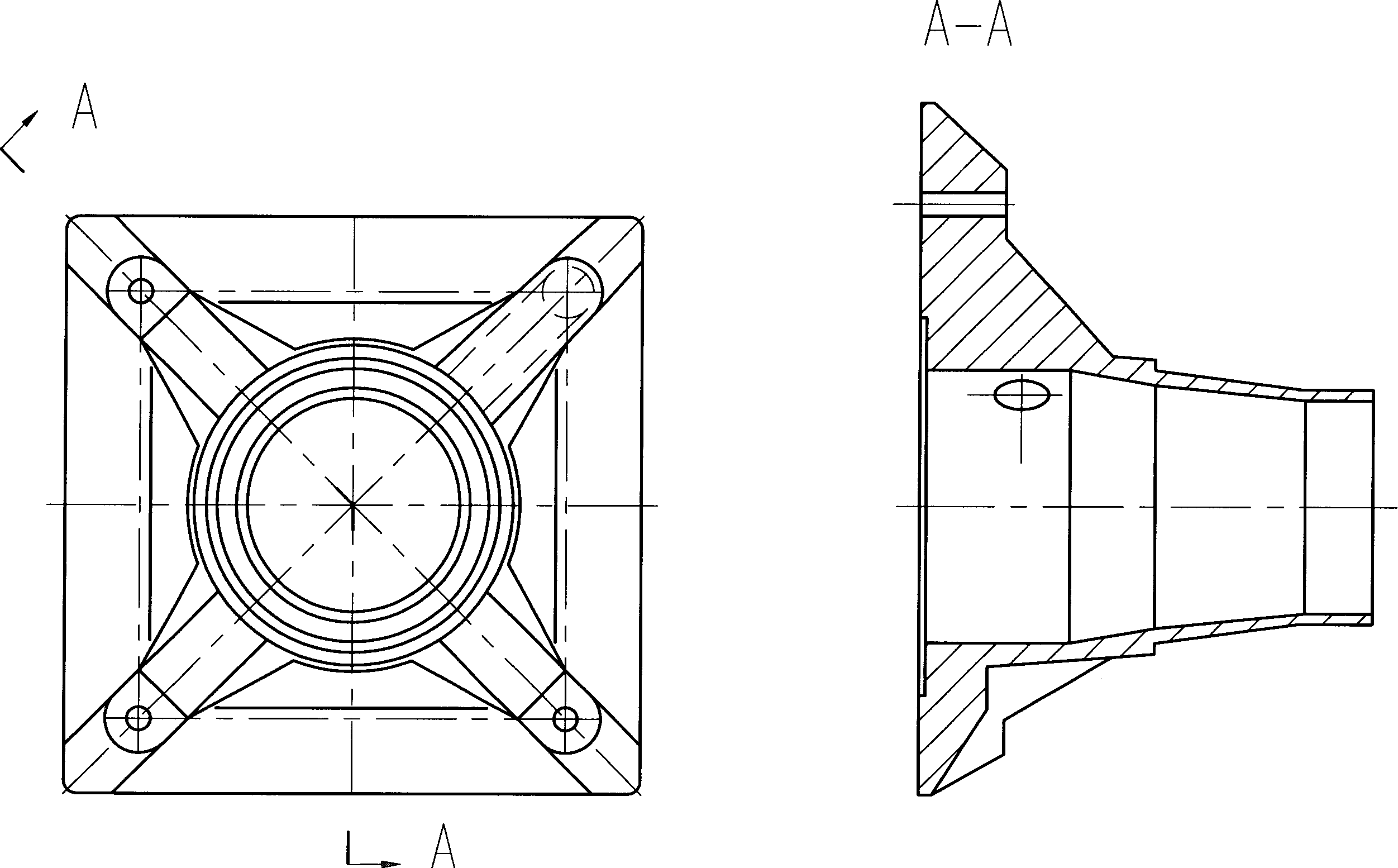

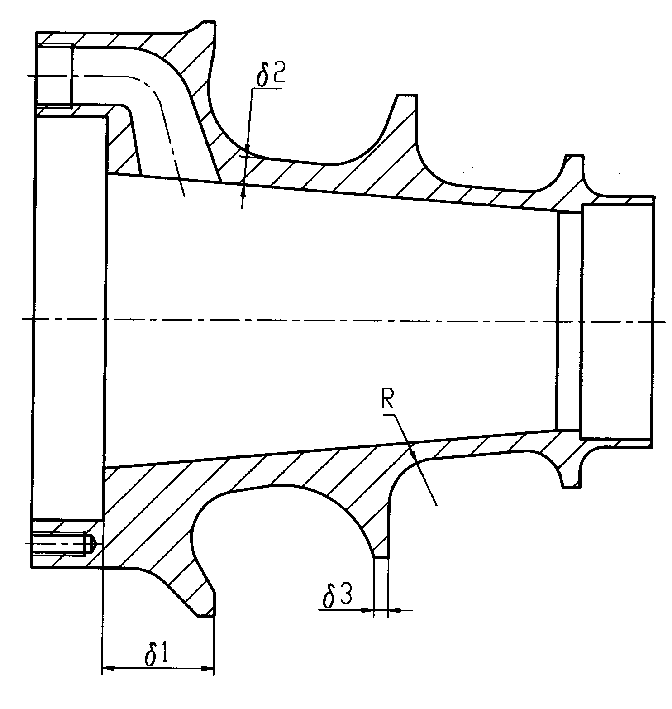

[0013] An anchor pad such as figure 1 Shown: The anchor plate is a round tower-shaped structure with a hollow interior and 2-4 steps in shape. The steps between each step and the tower body are arc-shaped, R=15-50mm, and the tower foot is for sinking anchors. The cylindrical part of the plate, the taper of the hollow tapered hole γ = 2 ~ 5 °, the thickness of the bearing plate δ 1 30-70mm, tower wall thickness δ 2 7 ~ 15mm, step thickness δ 3 7 ~ 12mm, the overall casting shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com