Semi-independent suspension frame for rear torsion beam of automobile

A torsion beam, semi-independent technology, applied in the direction of suspension, elastic suspension, vehicle parts, etc., can solve the problems of limited increase effect, broken reinforcement, large stress value at the connection between beam and trailing arm, etc., to avoid cracks. Produce, prevent the effect of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

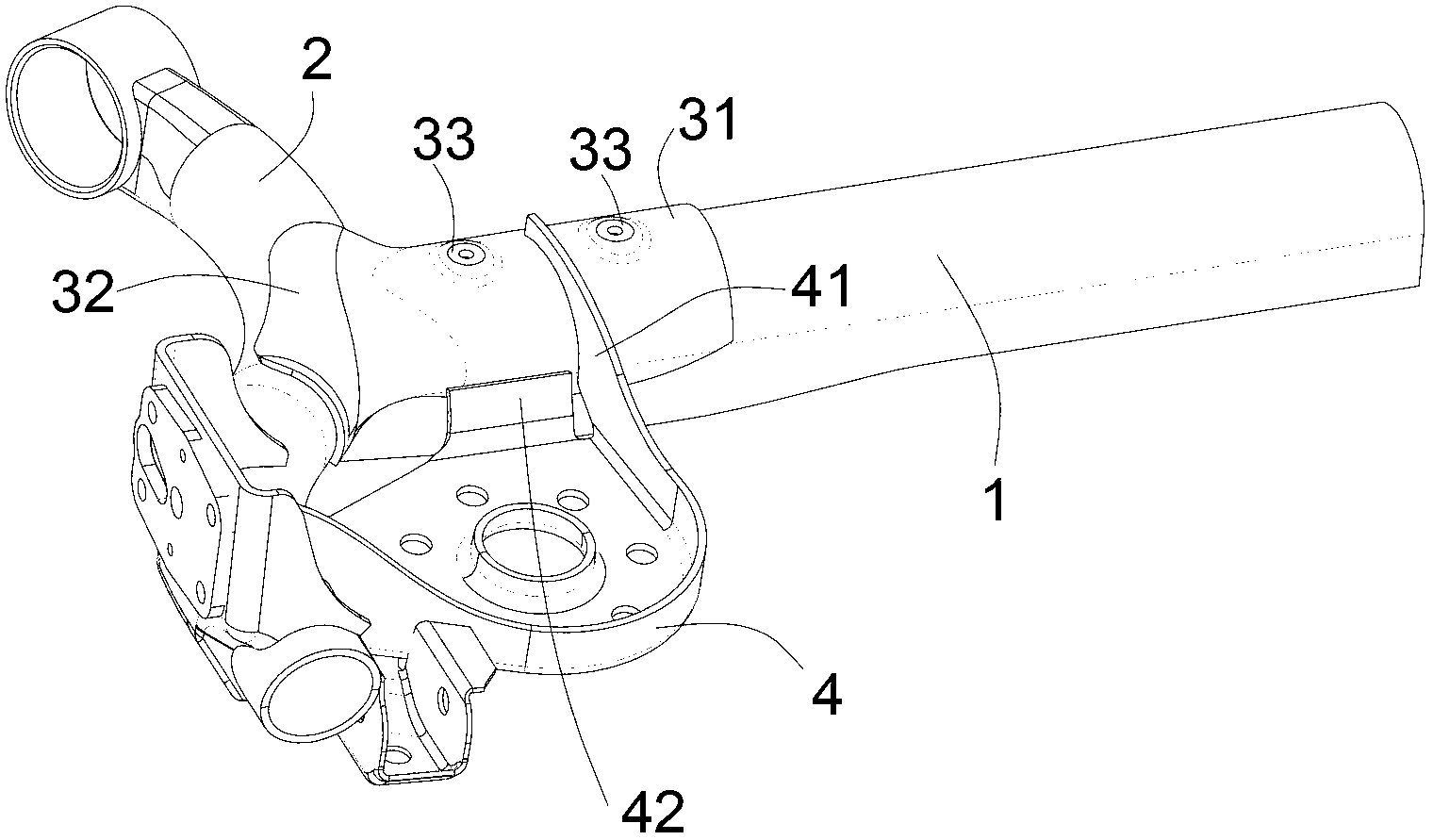

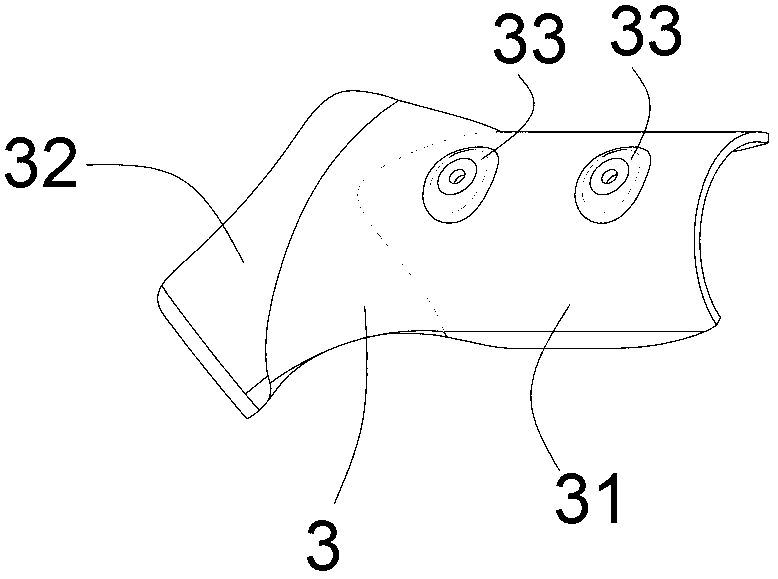

[0015] Such as figure 1 and figure 2 As shown, the rear torsion beam semi-independent suspension of an automobile includes a cross-section of a V-shaped or U-shaped cross beam 1, and a longitudinal arm 2 connected to both ends of the cross beam 1, and a spring seat 4 is arranged on the longitudinal arm 2. A reinforcement 3 is provided at the connection between the beam 1 and the longitudinal arm 2, and the reinforcement 3 includes a beam connection part 31 connected to the upper surface of the beam 1 with a cross-sectional shape matching the cross-sectional shape of the beam and connected with the longitudinal arm 2. The cross-sectional shape of the trailing arm connecting portion 32 matches the cross-sectional shape of the trailing arm. The upper surface of beam 1 is as figure 1 As shown, that is, the convex surface of the beam 1. The cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com