Walking type multipoint pushing construction method and walking type multipoint pushing construction system for steel box girder

A technology of jacking construction and construction method, which is applied in the directions of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as the complex structure of temporary pier tops, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

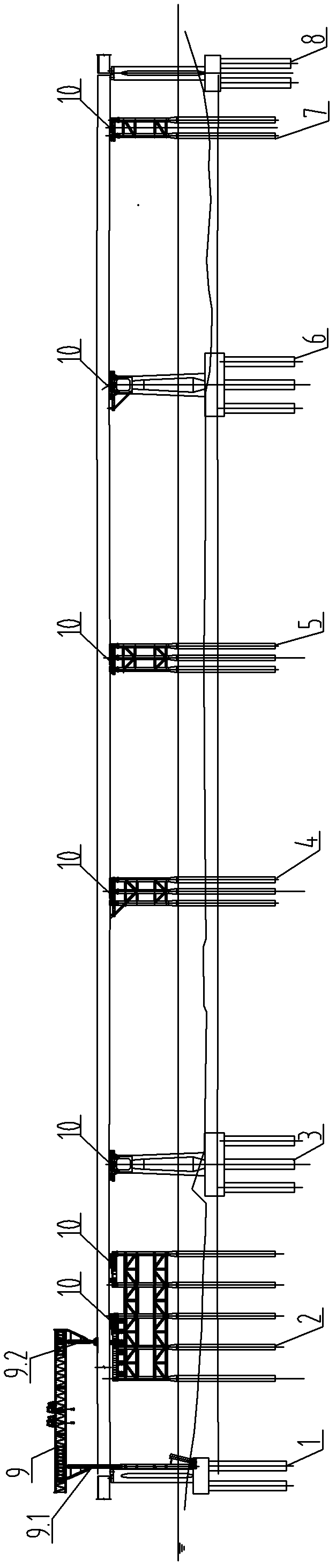

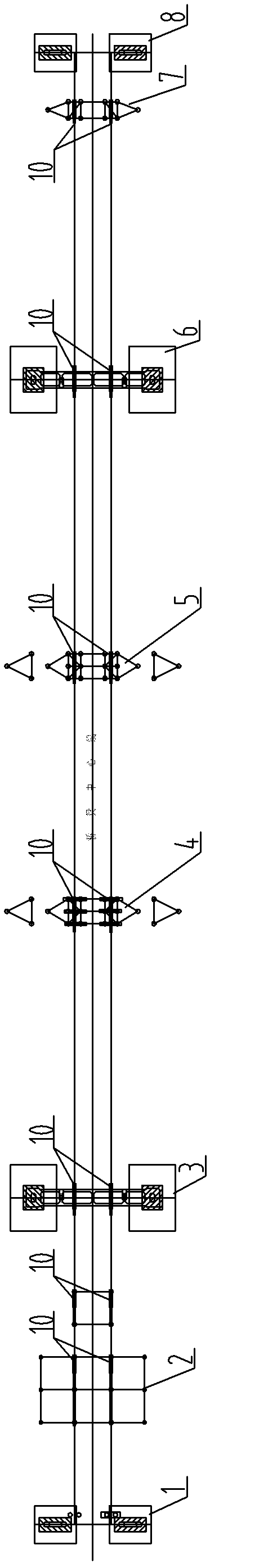

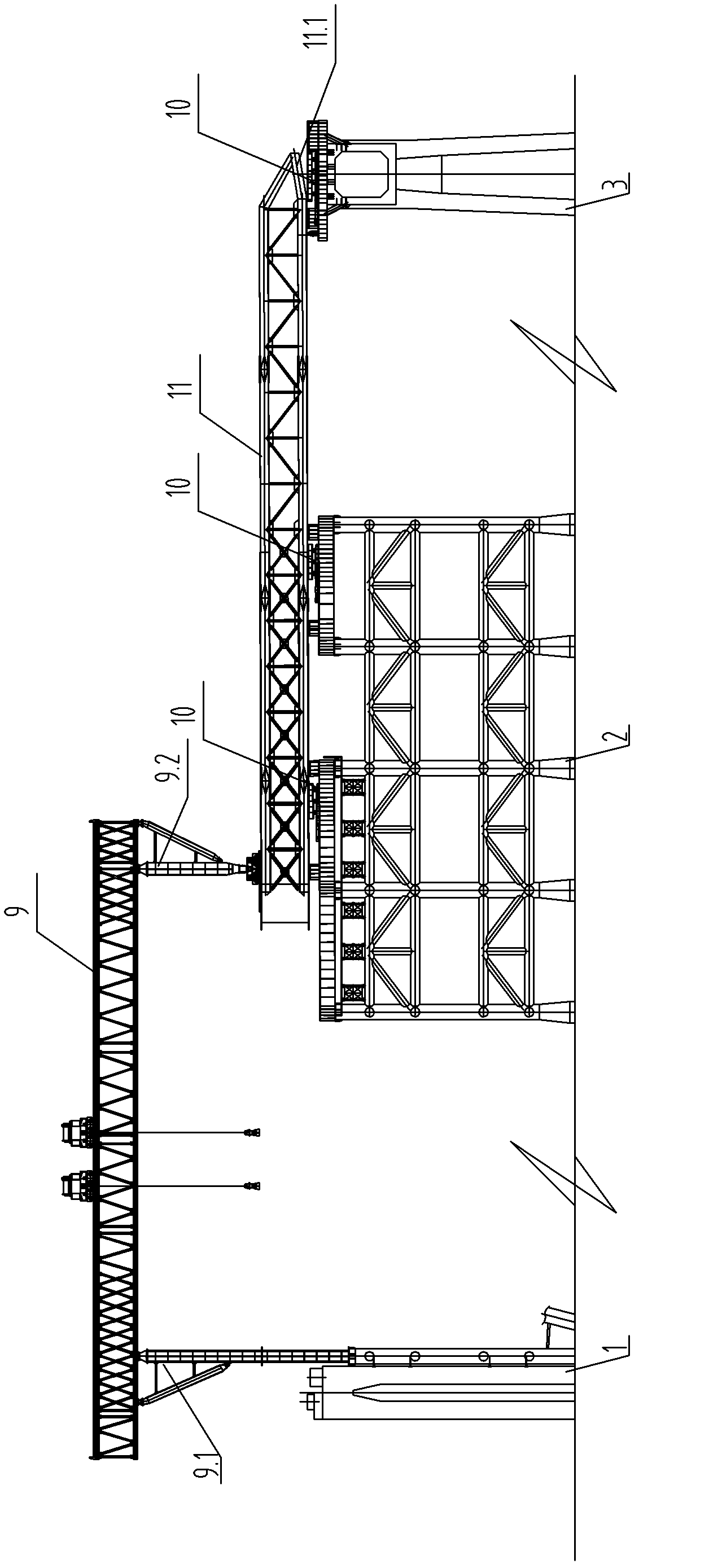

[0048] Such as figure 1 As shown, according to the steel box girder jacking process requirements and site conditions, at the design position of the main girder, along the direction of the longitudinal bridge, arrange in sequence: transition pier 1, assembly platform 2, main pier 3, temporary pier 4, temporary pier 5, Main pier 6, temporary pier 7 and transition pier 8 and other supporting structures. Set up anti-collision piers on the upstream and downstream sides of the temporary piers 4 and 5. Between the transition pier 1 and the assembly platform 2, a steel box girder lifting and fixing hanger 9 for hoisting, assembling and welding of the steel box girder is arranged. Pushing devices 10 are set on the assembly platform 2, each main pier and temporary pier.

[0049] in,

[0050] Such as image 3 As shown, the assembly platform 2 is an important construction site for steel box girder matching, welding and pushing, and adopts a plane T-shaped structure. Considering cost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com