Linear compressor of plate spring supporting system adopting two different types of lines

A linear compressor and support system technology, applied in mechanical equipment, machines/engines, liquid variable capacity machines, etc., can solve problems such as being difficult to overcome, and achieve the effect of avoiding natural frequency values, compact structure, and increased resonance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

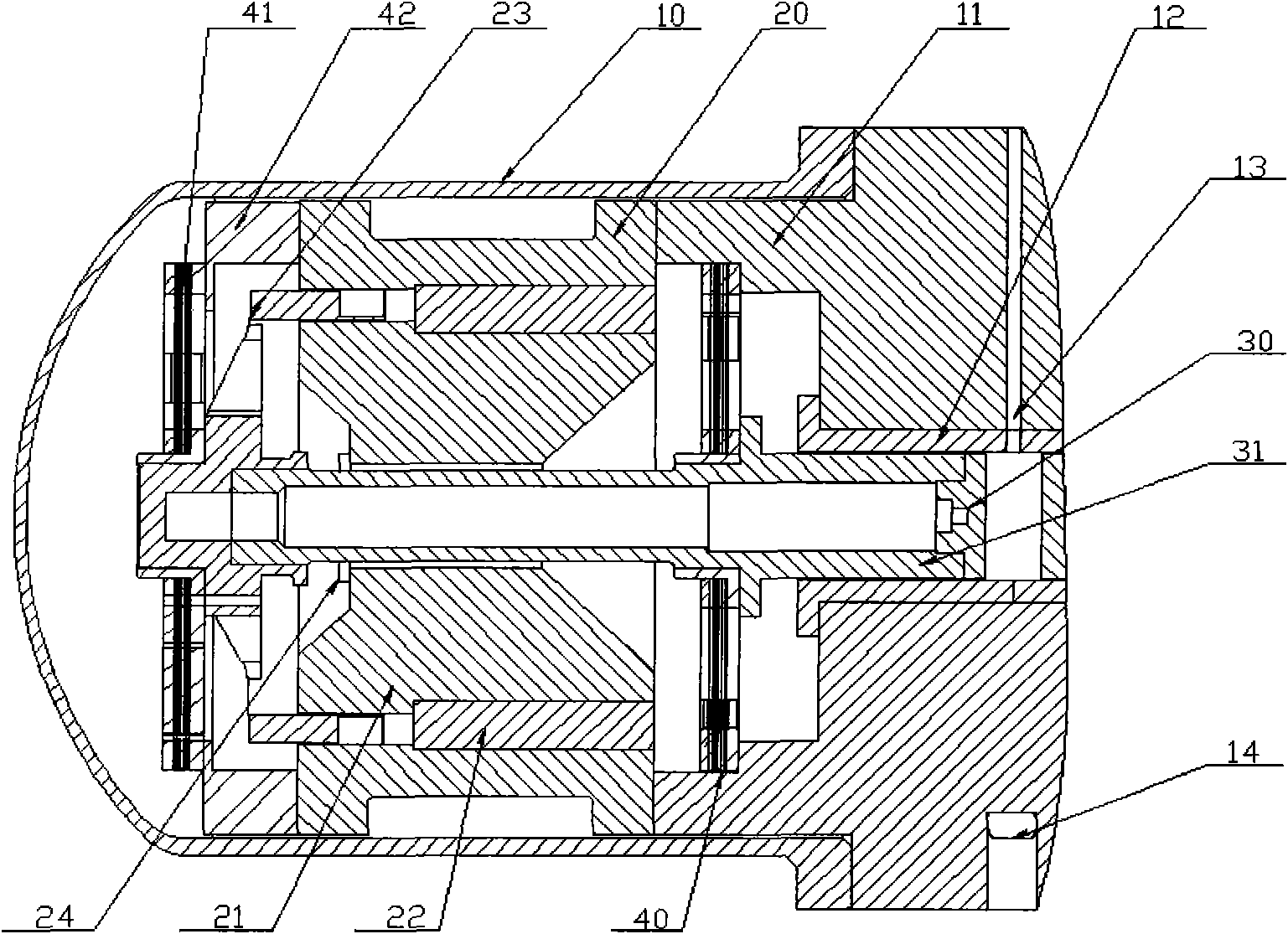

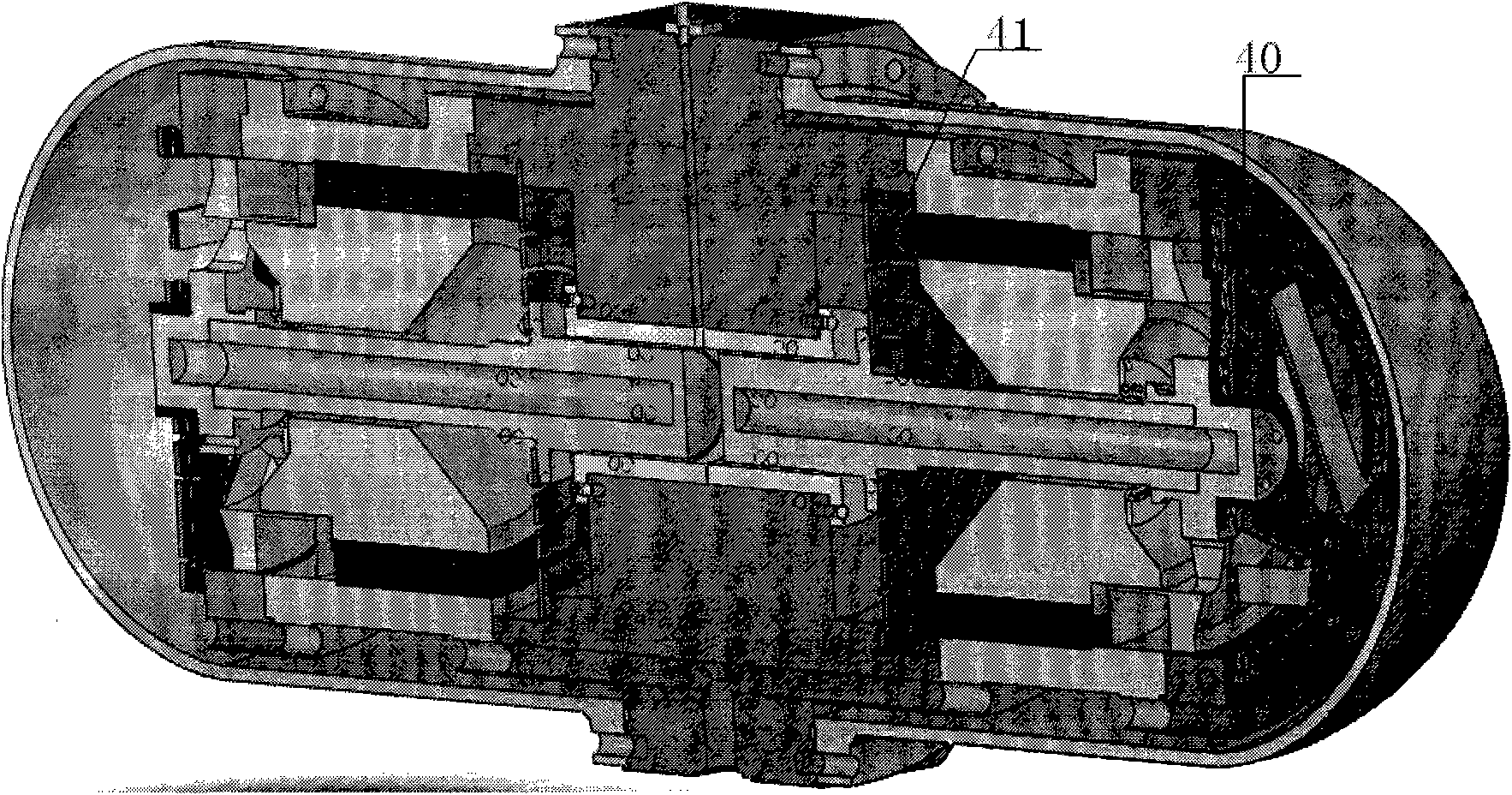

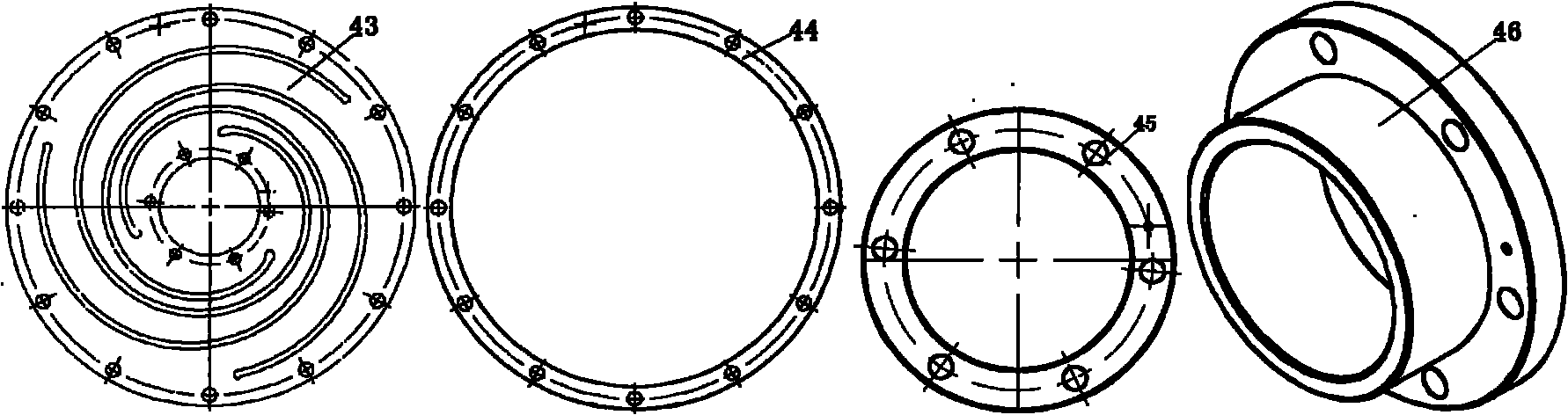

[0026] The following is based on Figure 1-Figure 8 A better example of the present invention is given and described in detail so as to better illustrate the structural and functional features of the present invention, rather than to limit the protection scope of the present invention.

[0027] refer to figure 1 and figure 2, the linear compressor using two different types of linear leaf spring support systems includes a compressor assembly 1, a linear motor assembly 2, a piston assembly 3 and a support system assembly 4; the compressor assembly 1 includes a compressor housing 10, a frame 11, Cylinder 12, exhaust orifice 13 and inflation orifice 14, compressor housing 10 are connected on the compressor frame 11 by screws, and rubber rings are used to seal between the contact surfaces to ensure the pressure on the back pressure side of the compressor; cylinder 12 It is fixed on the frame 11 by screws, and the double cylinders are symmetrically arranged. The exhaust port 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com