Rail road tank car traction and bolster device with beam structure

A beam and tank car technology, applied in the field of railway tank car pulling pillow device, can solve the problems of insufficient strength, high stress at the welding part of the tank plate and the tail of the drawing beam, etc., and achieve convenient manufacturing process, economical, practical and reliable, saving maintenance car cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the pillow device of the present invention is described in further detail:

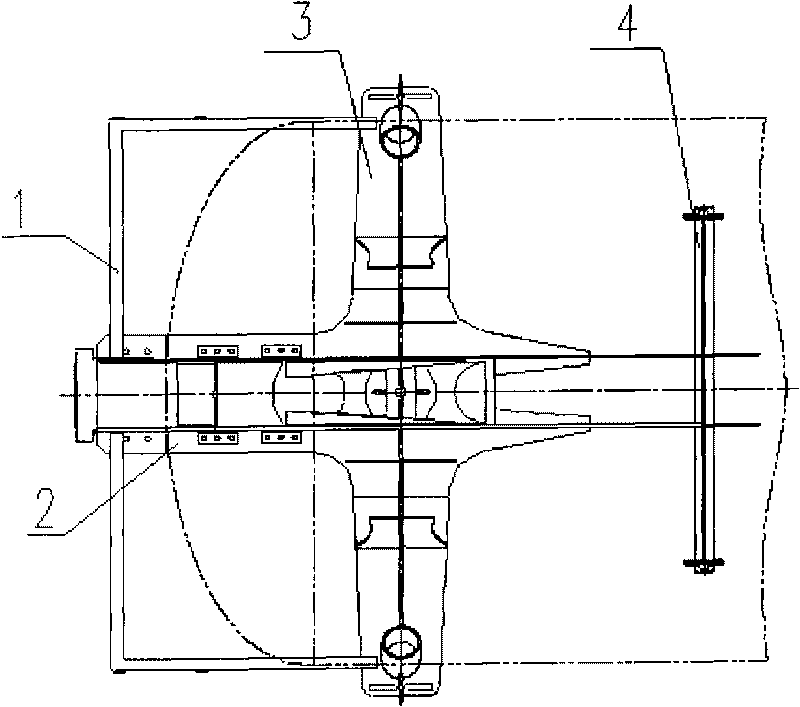

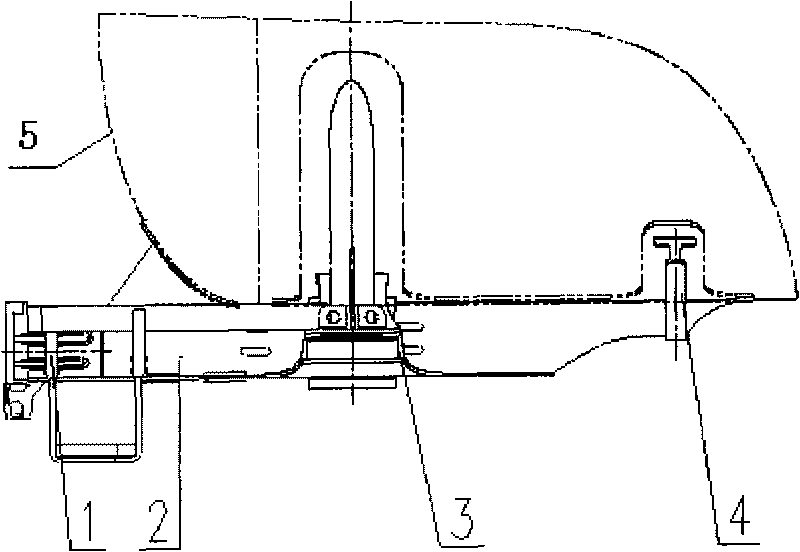

[0014] like figure 1 , figure 2 Middle: 1-end beam 2-drawing beam assembly 3-bolster beam assembly 4-beam assembly, 5 is the tank body.

[0015] The utility model pulling pillow device is mainly composed of drawing beam assembly 2, bolster assembly 3, crossbeam assembly 4 and the like.

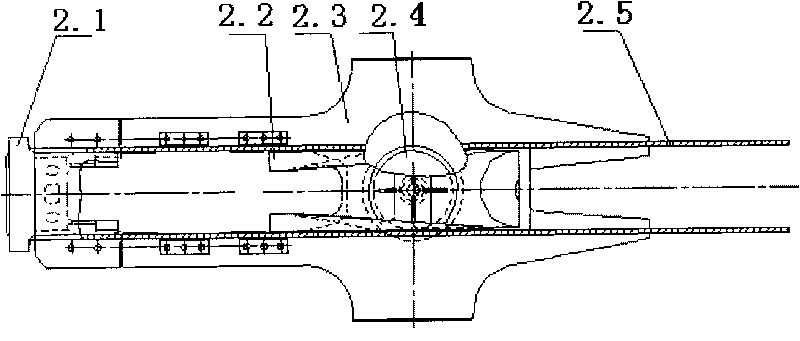

[0016] image 3 Composition diagram for drawing beam assembly: 2.1-impact seat, 2.2-center disk seat, 2.3-drawing beam lower cover, 2.4-upper center plate, 2.5-drawing beam web.

[0017] The traction beam assembly is welded by two webs and one lower cover plate, and the impact seat, integrated center plate seat and upper center plate are made of C-grade steel castings. Put the impact seat 2.1, center plate seat 2.2, traction beam lower cover plate 2.3, upper center plate 2.4, and traction beam web plate 2.5 on the positioning assembly welding platform, positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com