Steel-concrete composite beam adopting elastic concrete

A kind of elastic concrete and concrete technology, which is applied in the direction of load-bearing elongated structural members, climate sustainability, structural elements, etc., can solve the problems of fatigue damage, bearing capacity and durability reduction, etc., and achieve the reduction of repair rate, Effects of improved thermal conductivity and improved fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

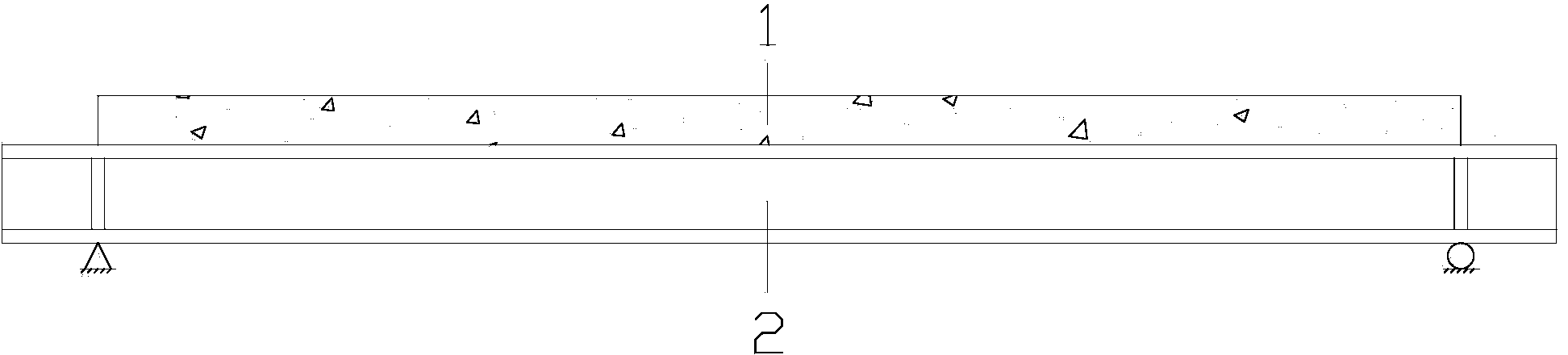

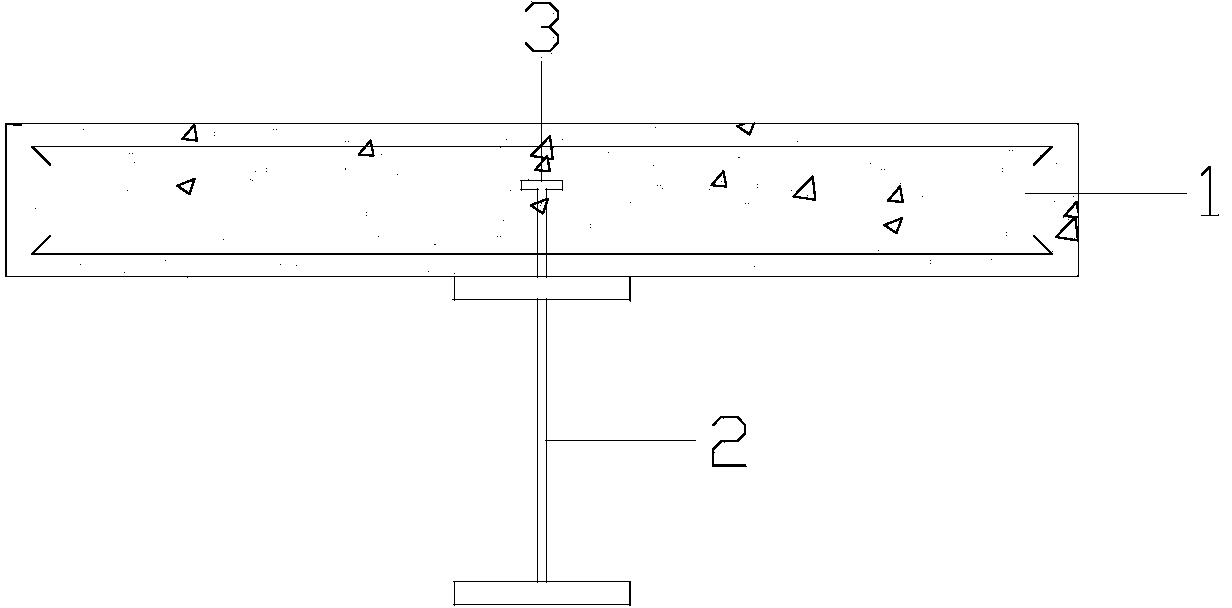

[0026] Such as figure 1 and figure 2 As shown, the steel-concrete composite beam using elastic concrete is mainly composed of three parts, namely elastic concrete slab 1, steel beam 2 and shear connector 3. The shear connector 3 is welded on the steel beam 2, and elastic concrete is poured on the steel beam 2 to form an elastic concrete slab 1, so that the shear connector 3 is placed in the elastic concrete to ensure that the elastic concrete and the steel beam 2 work together.

[0027] The steel-concrete composite beam is designed in accordance with the design method in the section of steel and concrete composite beams in the "Code for Design of Steel Structures" (GB50017-2003). The crack check calculation and structural measures must meet the current national standards "Code for Design of Steel Structures" (GB50017-2003) and "Code for Design of Concrete Structures" (GB50010-2010).

[0028] The elastic concrete slab 1 is poured on the steel beam 2 with the formwork support...

Embodiment 2

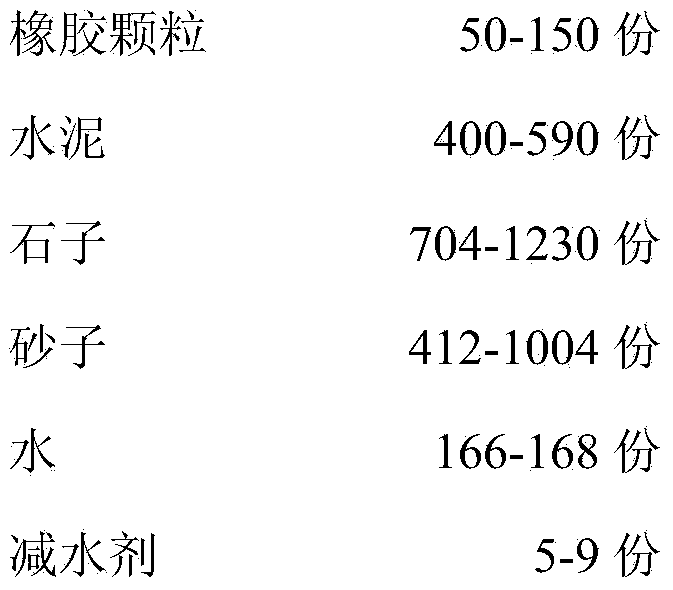

[0034] The only difference between Example 2 and Example 1 is that the elastic concrete used consists of 50 parts by weight of rubber particles, 400 parts of cement, 704 parts of stones, 708 parts of sand, 167 parts of water, and 5 parts of water reducing agent.

[0035] Through testing, it is found that the cubic compressive strength of the elastic concrete used in this embodiment can reach 45.1MPa, the modulus of elasticity is 2.790E+4, and the slump exceeds 100mm, which is suitable for engineering applications.

[0036] At the same time, through composite beam tests and finite element verification, it is found that in the steel-concrete composite beam of this embodiment, the slippage between steel and elastic concrete is 1.2 times the slippage between steel and ordinary concrete, that is, the combination of the former Stronger capability and greater flexibility. At the same time, the fatigue test found that after using the elastic concrete, the fatigue life of the steel-concr...

Embodiment 3

[0038] The only difference between Example 3 and Example 1 is that the elastic concrete used consists of 150 parts by weight of rubber particles, 495 parts of cement, 967 parts of stones, 1004 parts of sand, 166 parts of water, and 9 parts of water reducing agent.

[0039] The cubic compressive strength of the elastic concrete used in this embodiment can reach 38.5MPa, the modulus of elasticity is 1.445E+4, and the slump is 90mm, which is still suitable for engineering application.

[0040] At the same time, through composite beam tests and finite element verification, it is found that the steel-concrete composite beam of this embodiment has a slippage between steel and elastic concrete that is 1.4 times the slippage between steel and ordinary concrete, that is, the combination of the former Stronger capability and greater flexibility. At the same time, the fatigue test found that after adopting the elastic concrete, the fatigue life of the steel-concrete composite beam is 1.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com