Preparation method for metal matrix composite material sample suitable for EBSD (Electron Backscattered Diffraction) detection

A composite material, metal-based technology, applied in the preparation of test samples, material analysis using wave/particle radiation, analyzing materials, etc., to achieve low stress values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

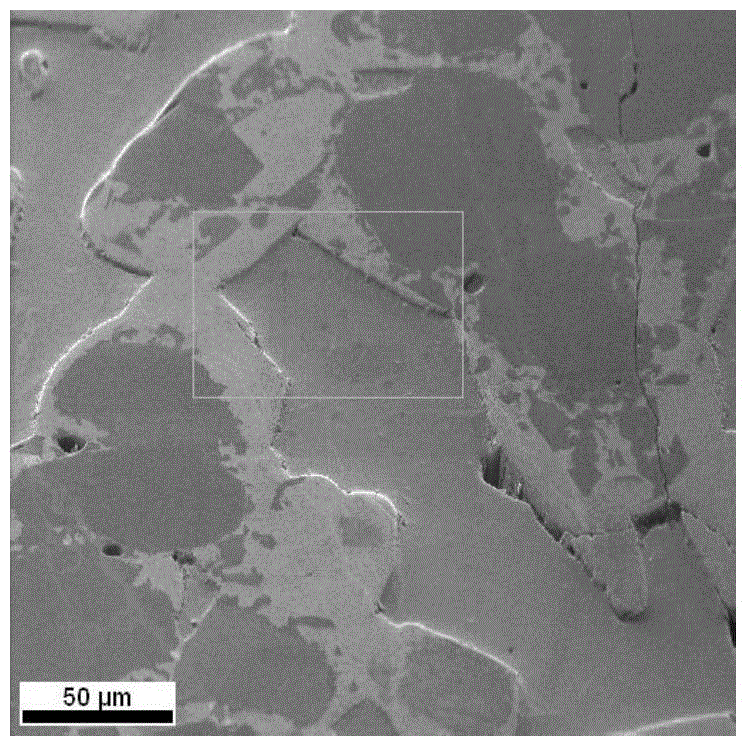

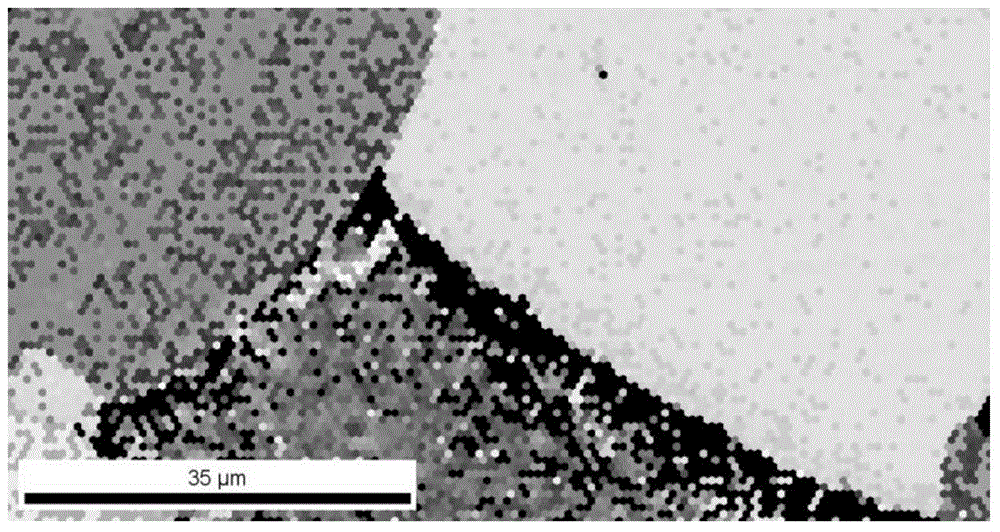

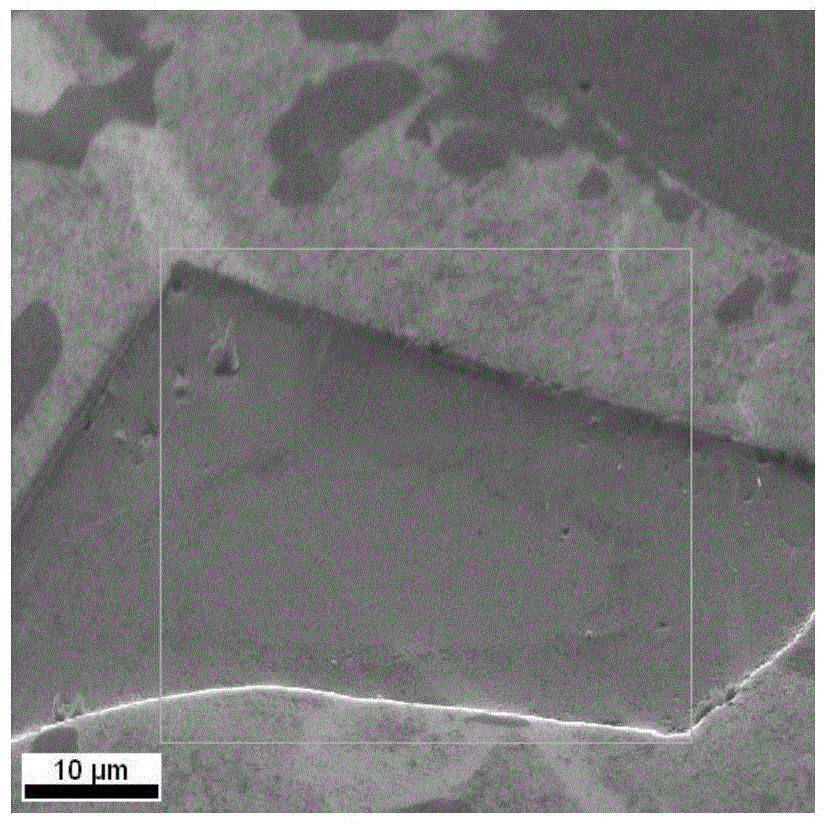

Image

Examples

Embodiment 1

[0032] (1) Molybdenum wire is used as the cutting wire, and the cutting speed is 0.1mm / min on SiC 3D Extract the EBSD test sample 1 with a size of 3×4×10mm from the Al metal matrix composite material;

[0033] (2) Use SiC sandpaper of different meshes to grind the EBSD sample 1 successively from low to high; use SiO with different sizes of internal polishing particles 2 The solution polishes the samples polished by sandpaper from large to small; among them, the number of sandpaper meshes is from 200 mesh to 2000 mesh, SiO 2 The size of the polishing particles inside the solution ranges from 1.5 μm to 0.5 μm.

[0034] (3) Vibration polishing is performed on the EBSD sample 2 to be tested, and the vibration polishing time is 5min; the vibration frequency is 1000Hz, and a load of 50g is applied; after the vibration polishing is completed, ion polishing is performed on the EBSD sample 2 to be tested after the vibration polishing process , the ion polishing time is 1min; the curr...

Embodiment 2

[0038] (1) Using molybdenum wire as the cutting wire, extract an EBSD sample 1 with a size of 3×4×10mm on the SiCp / Cu metal matrix composite material at a cutting speed of 2mm / min;

[0039] (2) Using different mesh Al 2 o 2 Sandpaper, grind the EBSD test sample 1 successively from low to high; use Al with different sizes of internal polishing particles 2 o 3 After the solution polished the sandpaper, the sample was polished successively from high to low; among them, the number of sandpaper was from 200 mesh to 2000 mesh, Al 2 o 3 The size of the polishing particles inside the solution ranges from 1.5 μm to 0.5 μm.

[0040](3) Vibration polishing is carried out on the EBSD sample 2 to be tested, and the vibration polishing time is 60min; the vibration frequency is 10000Hz, and a load of 500g is applied; after the vibration polishing is completed, ion polishing is performed on the EBSD sample 2 to be tested after the vibration polishing process , the ion polishing time is 5...

Embodiment 3

[0044] The detection material is SiC p / Al metal matrix composite material, the preparation process is as follows:

[0045] (1) Molybdenum wire is used as the cutting wire, and the cutting speed is 1mm / min on SiC p Extract the EBSD test sample 1 with a size of 3×4×10mm from the Al metal matrix composite material;

[0046] (2) Use SiC sandpaper of different meshes to grind the EBSD sample 1 successively from low to high; use Al with different sizes of internal polishing particles 2 o 3 After the solution polished the sandpaper, the sample was polished successively from high to low; among them, the number of sandpaper was from 200 mesh to 2000 mesh, Al 2 o 3 The size of the polishing particles inside the solution ranges from 1.5 μm to 0.5 μm.

[0047] (3) Vibration polishing is performed on the EBSD sample 2 to be tested, and the vibration polishing time is 30min; the vibration frequency is 5000 Hz, and a load of 200g is applied; after the vibration polishing is completed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com