Drum vent

A technology of air vents and drums, which is applied in the field of air vent devices, and can solve problems such as loss of air vent performance, condensation of chemicals, and drying out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

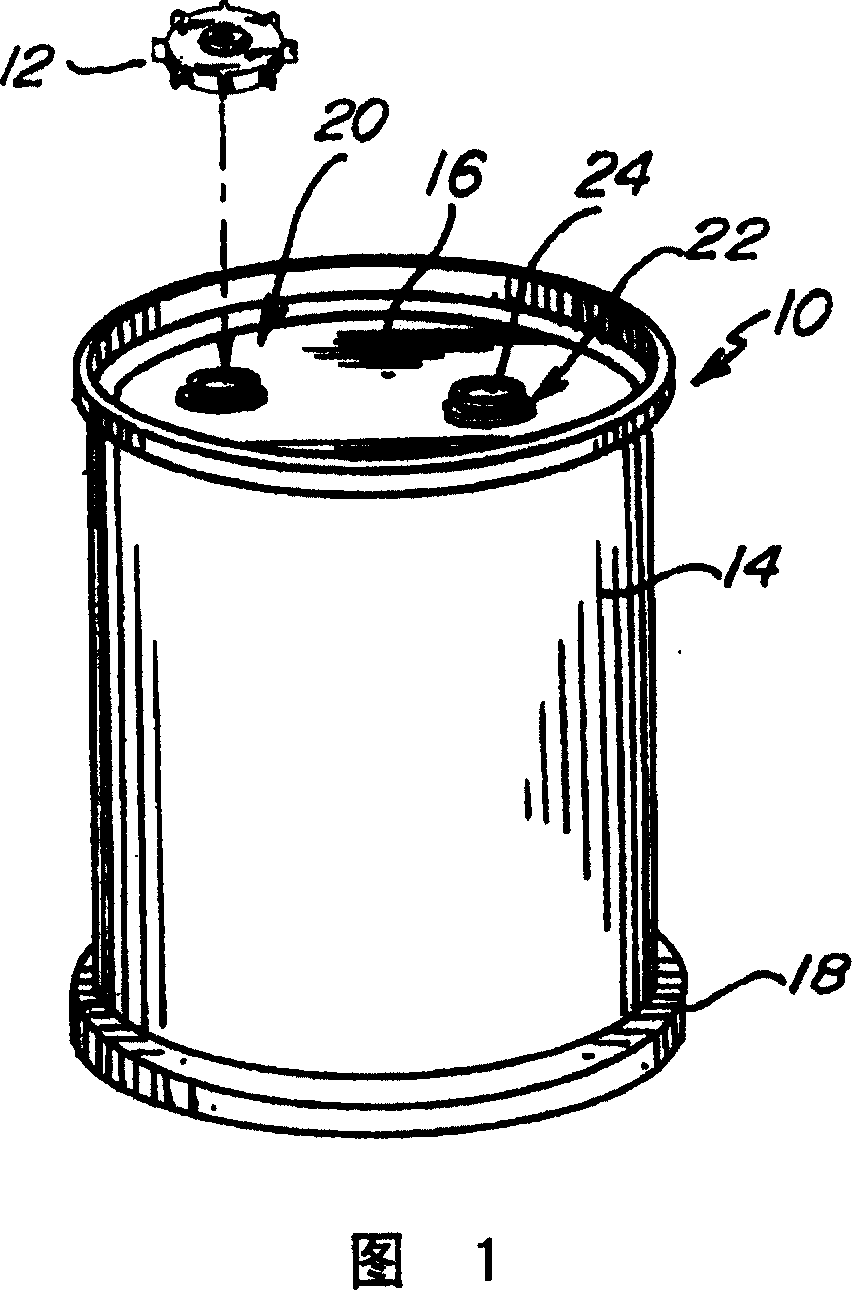

[0023] Referring to Figures 1 and 2, there is shown a drum shell 10 and vent plug 12 in accordance with the present invention. FIG. 1 shows in perspective a blow molded drum 10 generally comprising a cylindrical wall portion 14 , a top structure 16 and a bottom structure 18 . The top structure 16 includes a first barrel opening 20 and a second barrel opening 22 . The second barrel hole is closed with a standard plug 24 which sealingly engages in the second barrel hole 22 . The vent plug 12 is sealingly engaged within the first barrel bore 20 . The first and second barrel bores 20 , 22 generally have internal threads that threadably engage external threads on the vent plug 12 and the standard plug 24 . It should be appreciated, however, that any alternative means known to those of ordinary skill in the art may be used to engage the bore plug 12 and bung 24 within the barrel bores 20, 22.

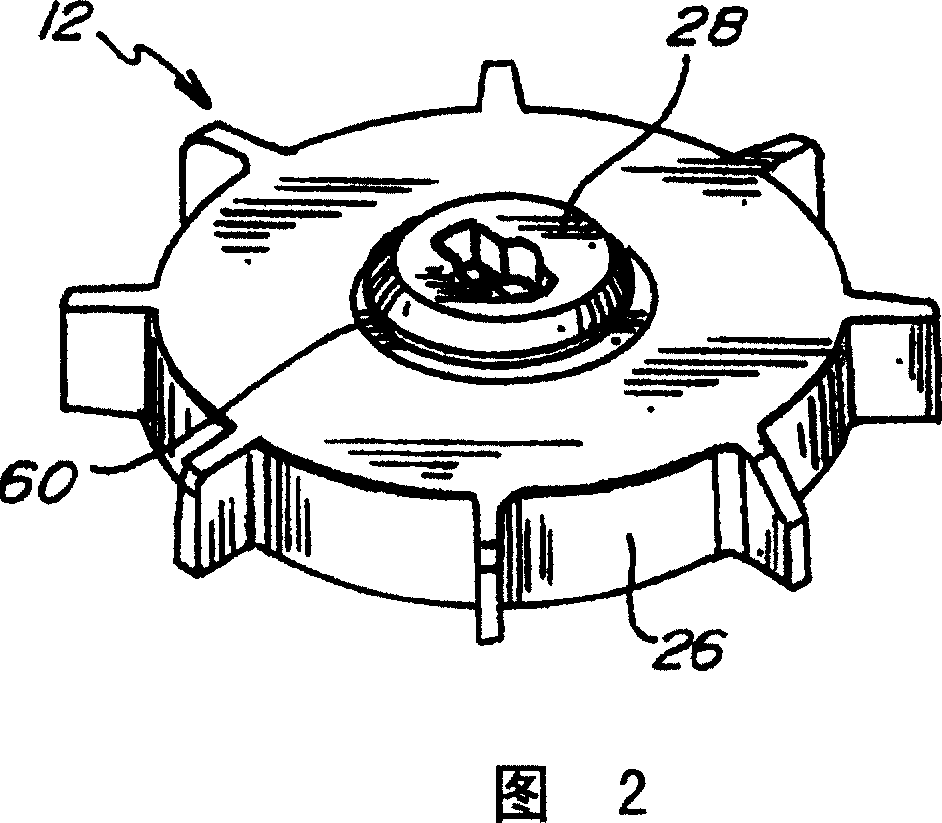

[0024] FIG. 2 shows a perspective view of the vent plug 12 . The vent plug 12 general...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com