Clamping device for checking fatigue property of high-pressure turbine blade of aero-engine

A technology for aero-engines and high-pressure turbines, which is applied in the direction of measuring devices, strength characteristics, and the use of applied repetitive force/pulsation force to test the strength of materials, etc. It can solve problems such as blade tenon tooth breakage, impossibility of testing, and inability to accurately evaluate blade strength performance. , to achieve the effect of correctly evaluating the strength performance and solving the problem of tenon tooth fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, which are explanations rather than limitations of the present invention.

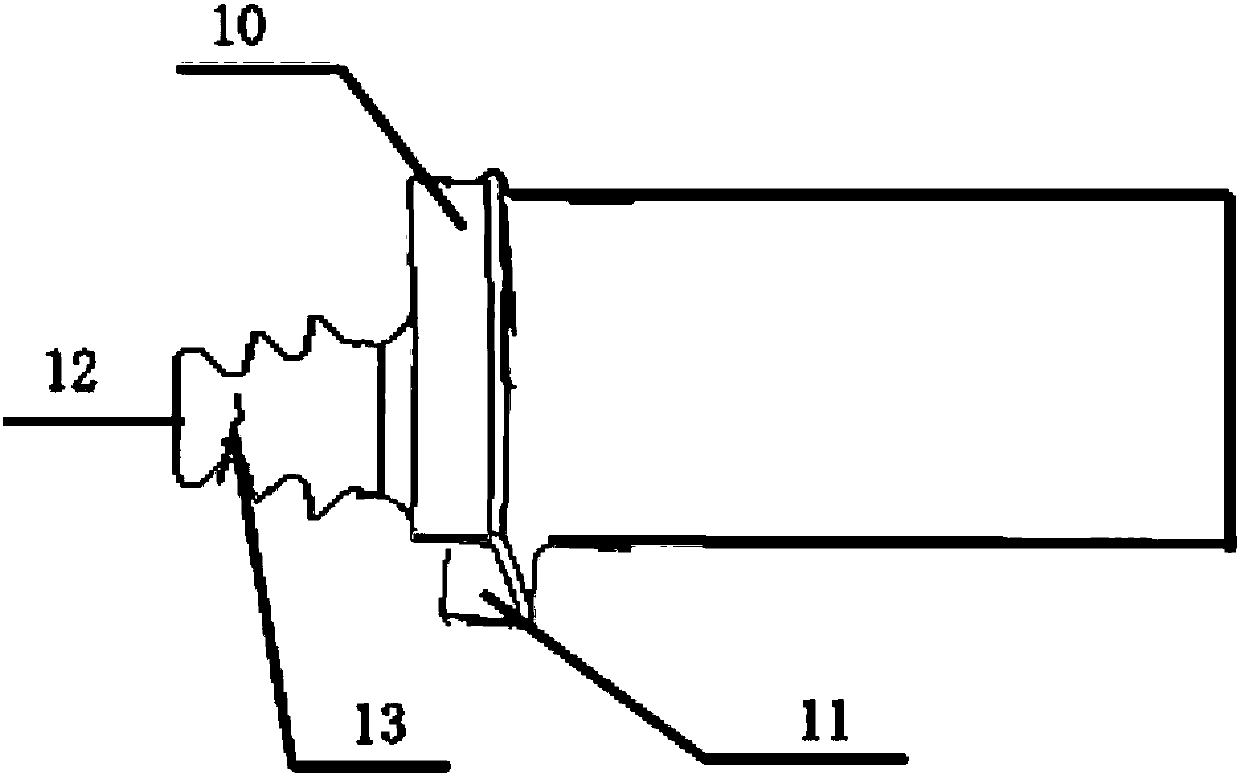

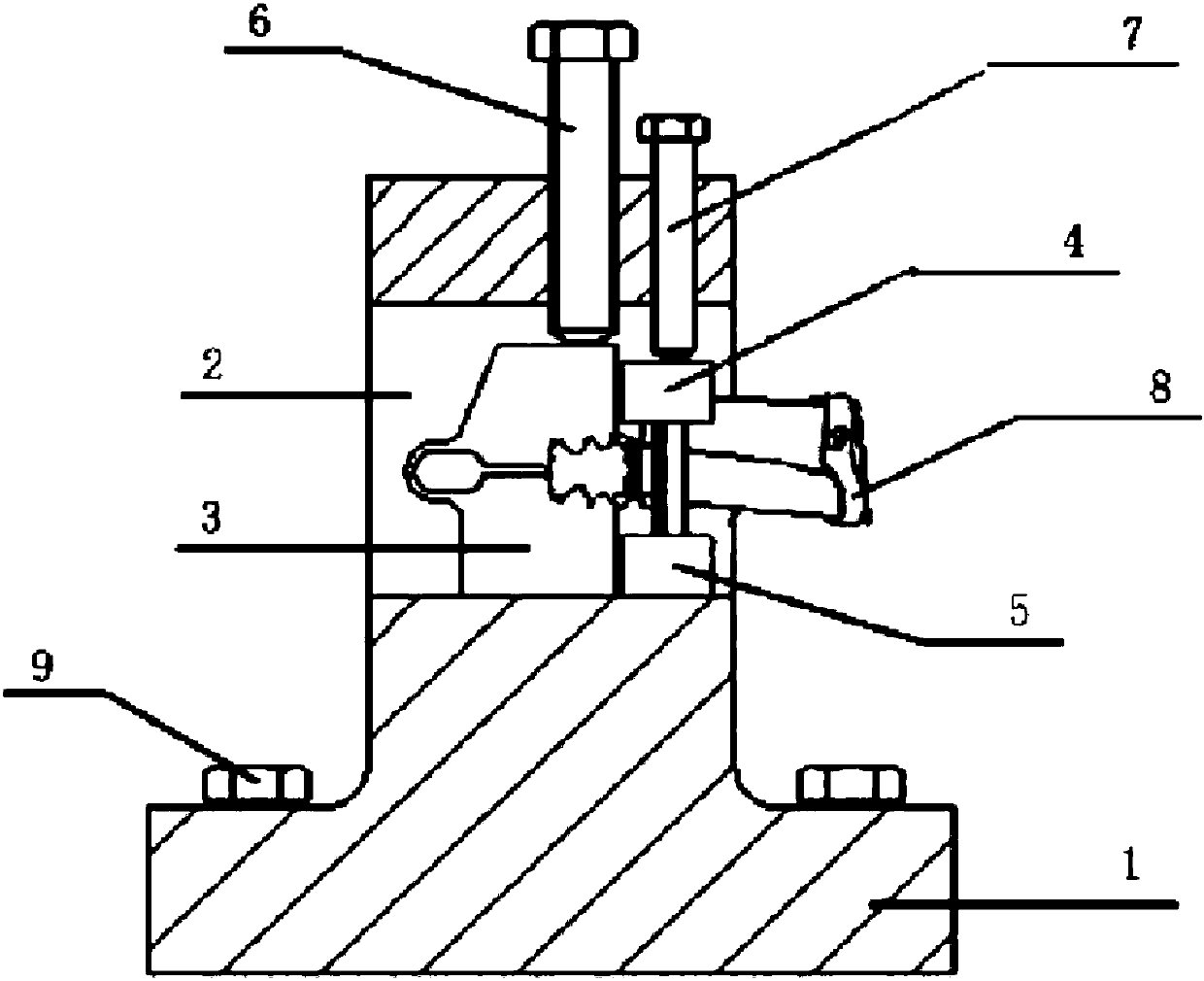

[0011] Such as figure 2 As shown, the specific embodiment of the present invention provides a clamping device for the fatigue performance assessment of high-pressure turbine blades of aero-engines, including a base 1, a clamping block 3, an upper pressing block 4 and a lower pressing block 5; the base 1 is provided with a gantry 2; the clamping block 3 is used to clamp the high-pressure turbine blade of the aero-engine and placed in the gantry 2, and a compression bolt 6 is also arranged above the clamping block 3; the upper pressing block 4 and the The lower pressing block 5 is respectively placed at the upper edge plate 10 and the lower edge plate 11 of the high-pressure turbine blade of the aero-engine, and plays the role of stabilizing the upper edge plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com