Steel hoop support system of jacking bridge

A support system and steel pipe support technology, which is applied to bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems of large number of shoulder pole distribution beams, large impact of cover beams, and high cost of foundation disposal, so as to save reinforcement treatment and reduce construction Difficulty and safety risks, the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

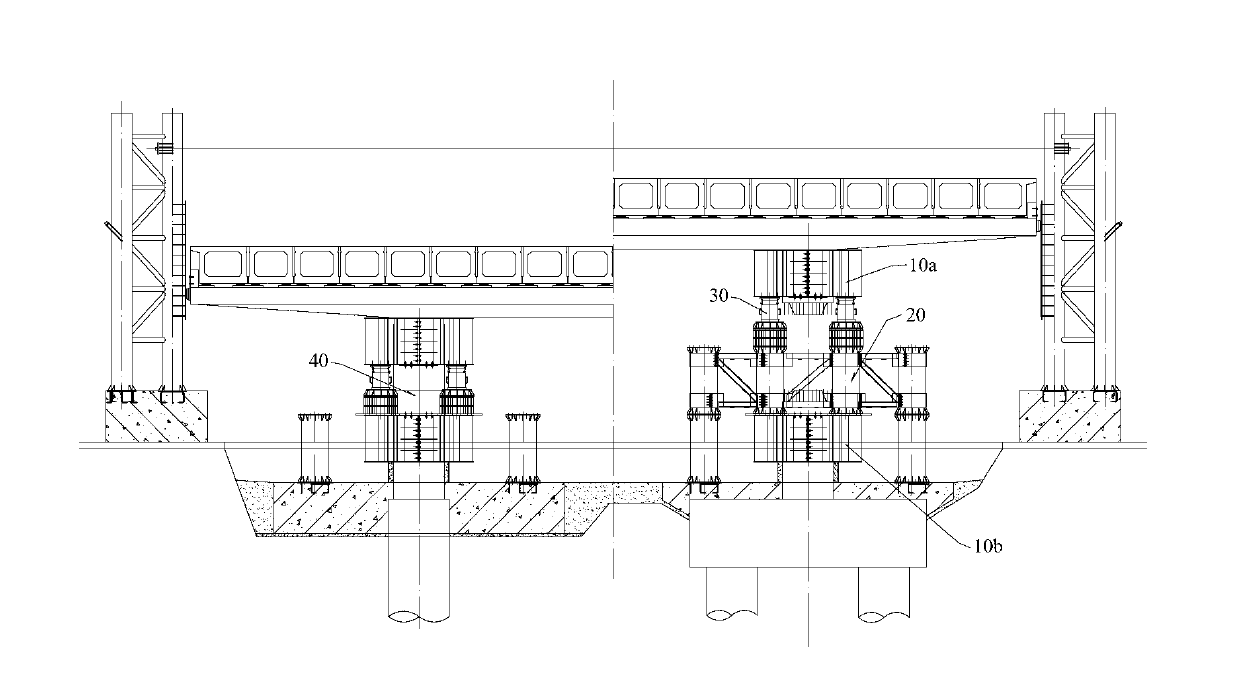

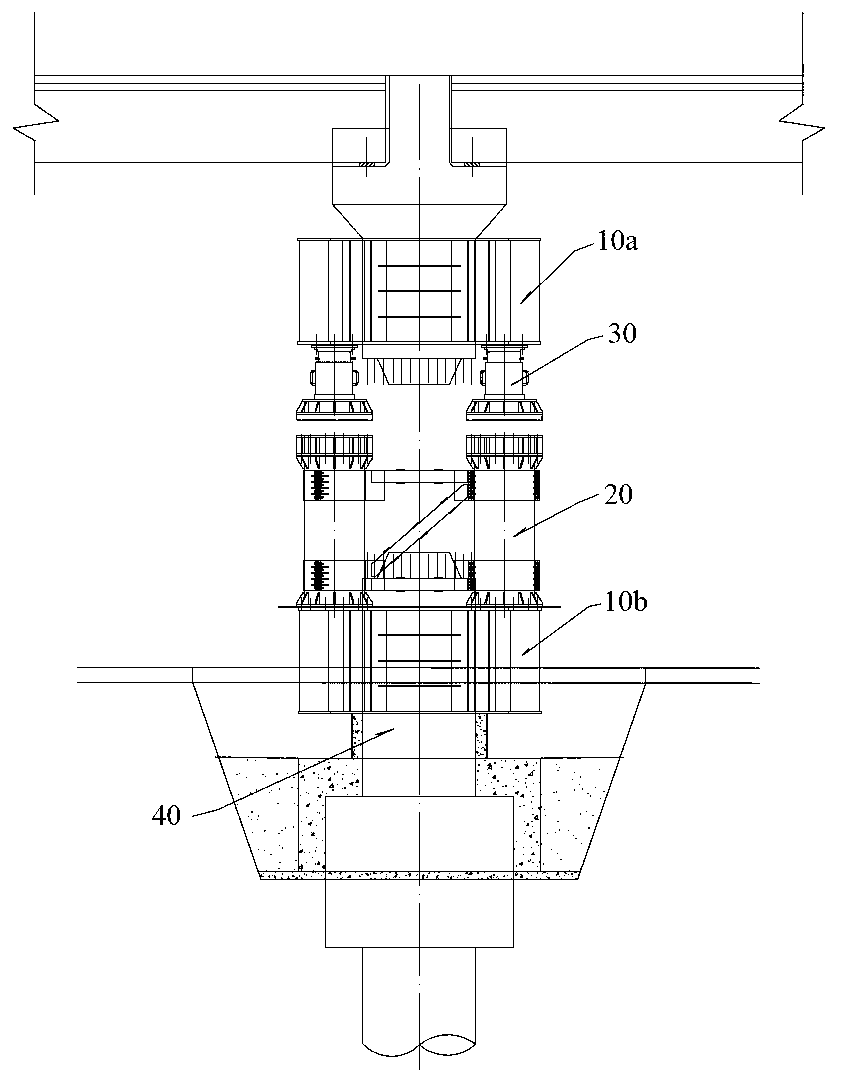

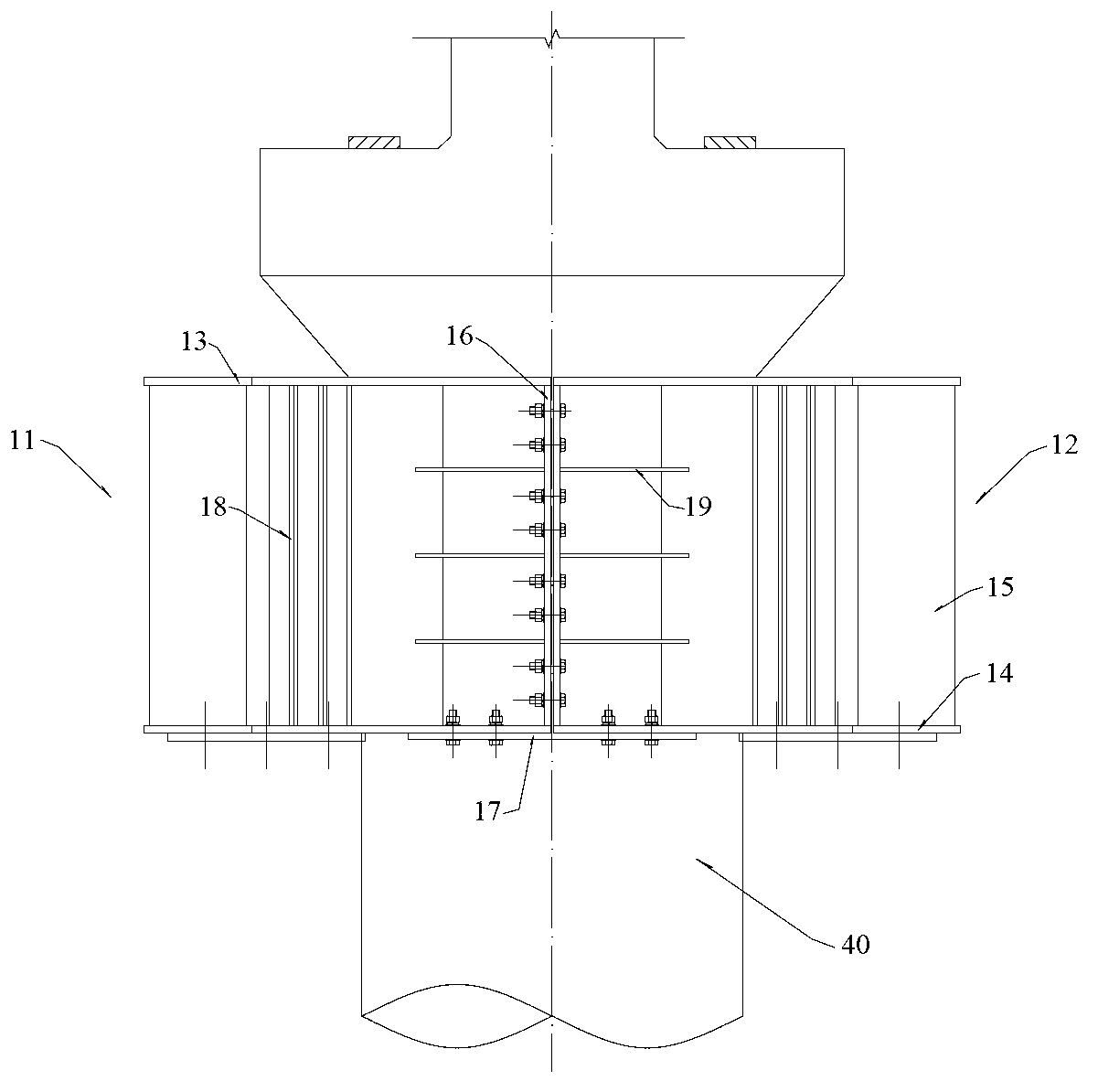

[0015] refer to figure 1 with figure 2 , the jacking bridge steel hoop support system of the present invention comprises the upper end steel hoop 10a and the lower end steel hoop 10b which are fixed on the upper and lower ends of the original reinforced concrete pier column 40 of the bridge by applying pre-tightening force, and installed and fixed on the lower end For the steel pipe support 20 on the steel hoop 10b, a hydraulic jack system 30 is set between the upper steel hoop 10a and the upper end of the steel pipe support 20 . Utilize the upper end steel hoop 10a and the lower end steel hoop 10b to replace the traditional pole distribution beam to directly bear the lifting force of the hydraulic jack system 30, and the foundation of the bracket also adopts the steel pipe bracket 20 supported by the lower end steel hoop 10b, by applying preload The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com