Device and method for axial loading to assist bulging of magnetic pulse pipe

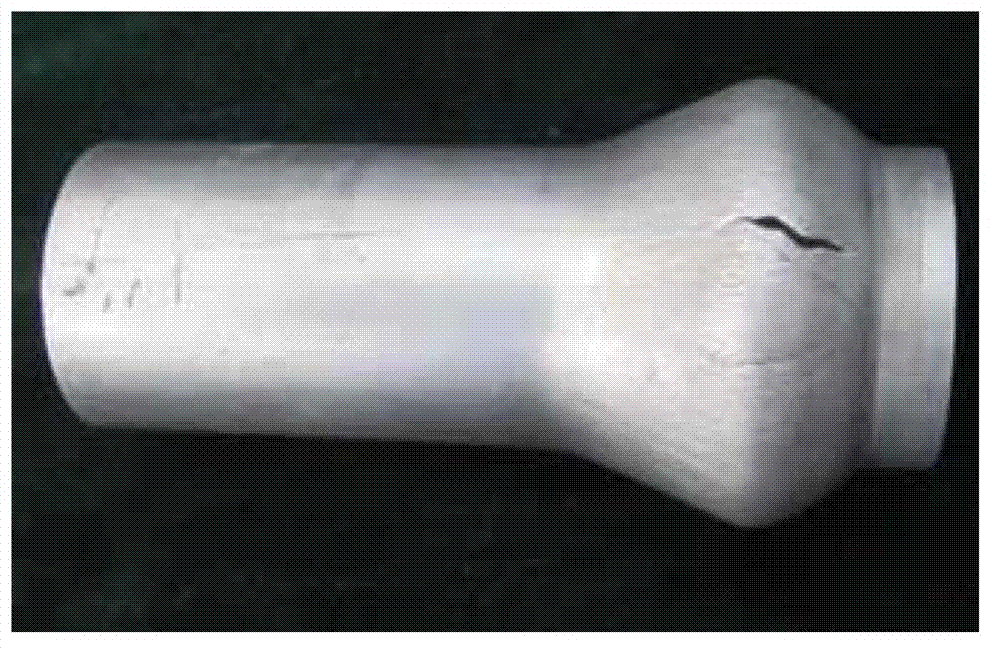

A technology of axial loading and auxiliary magnetic, which is applied in the field of magnetic pulse tube bulging device, can solve the problems of uneven deformation, cracking and excessive thinning of the tube wall, so as to increase the forming limit, improve the formability and improve the axial The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

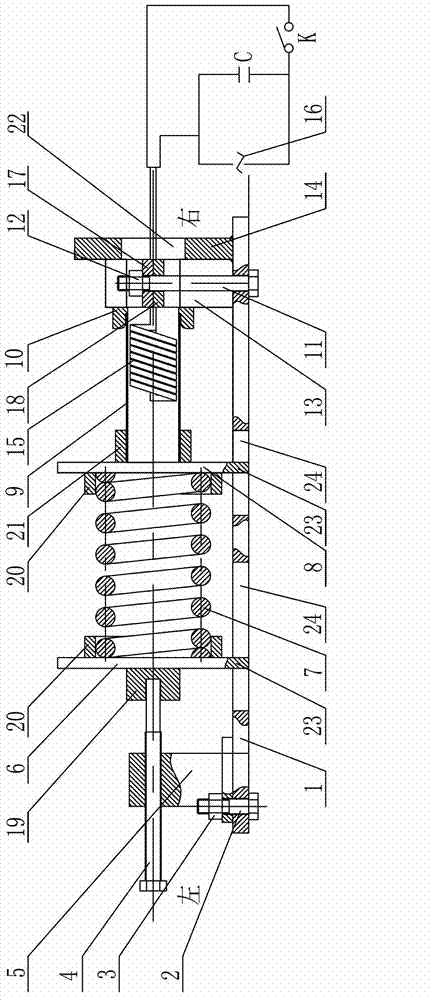

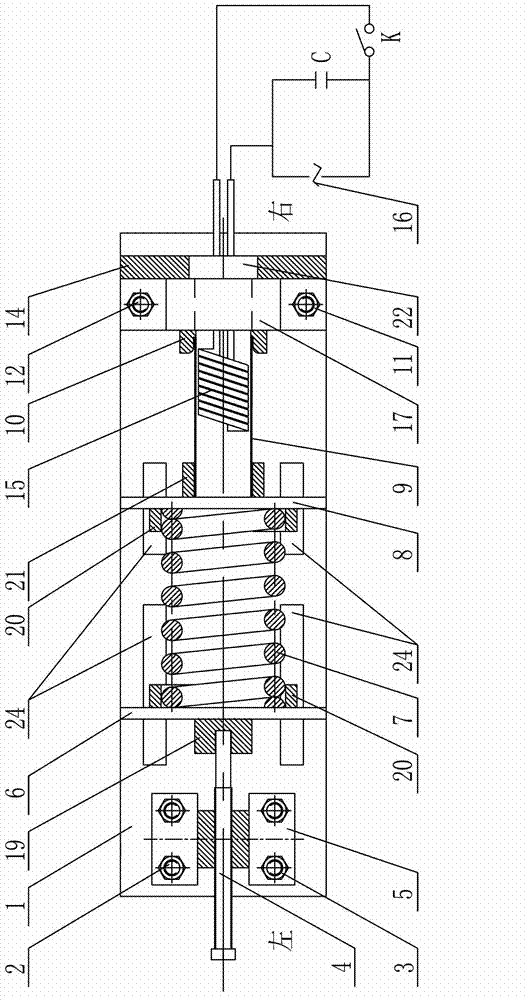

[0018] Specific embodiment one: combine 1 and figure 2 Explain that the device for axial loading assisted magnetic pulse tube bulging in this embodiment includes a rectangular bottom plate 1, a screw 4, a screw guide block 5, two push plates, a spring 7, a pipe stopper 10, Fixture 13, baffle plate 14, coil 15, power supply 16, lead screw limit sleeve 19, pipe fitting sheath 21, capacitor bank C, discharge control switch K and two spring limit sleeves 20; two push plates are respectively left Push plate 6 and right push plate 8, fixture is made up of upper clamp block 17 and lower clamp block 18,

[0019] Lead screw guide block 5, two push plates, fixture 13 and baffle plate 14 are arranged side by side on the rectangular base plate 1 successively from left to right along the length direction of rectangular base plate 1, lead screw guide block 5 (through four first bolts 2 and four first nuts 3) are detachably connected to the rectangular bottom plate 1, the baffle plate 14 i...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 and figure 2 Note that the coil 15 in this embodiment is composed of a single wire wound spirally on the coil frame for multiple turns, and two adjacent turns of the wire are separated by a high-voltage insulating material, and the surface of the coil 15 is made of a high-voltage insulating material (such as polyimide film or epoxy glass cloth) covered. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 and figure 2 Description, the spring 7 in this embodiment is made of 60Si 2 Made of Mn material. With such a design, a relatively large axial preload is required to affect the bulging of the pipe fitting 9, while 60Si 2 Mn material has good elasticity and good tempering stability, and is suitable for large-load springs. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com