Disk workpiece processing method and structure

A processing method and workpiece technology, which is applied in the field of disc workpiece processing and structure, can solve the problems of long cycle time, long processing time, and low quality of parts, and achieve the effects of changing the stress state, improving processing accuracy, good drainage and chip removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

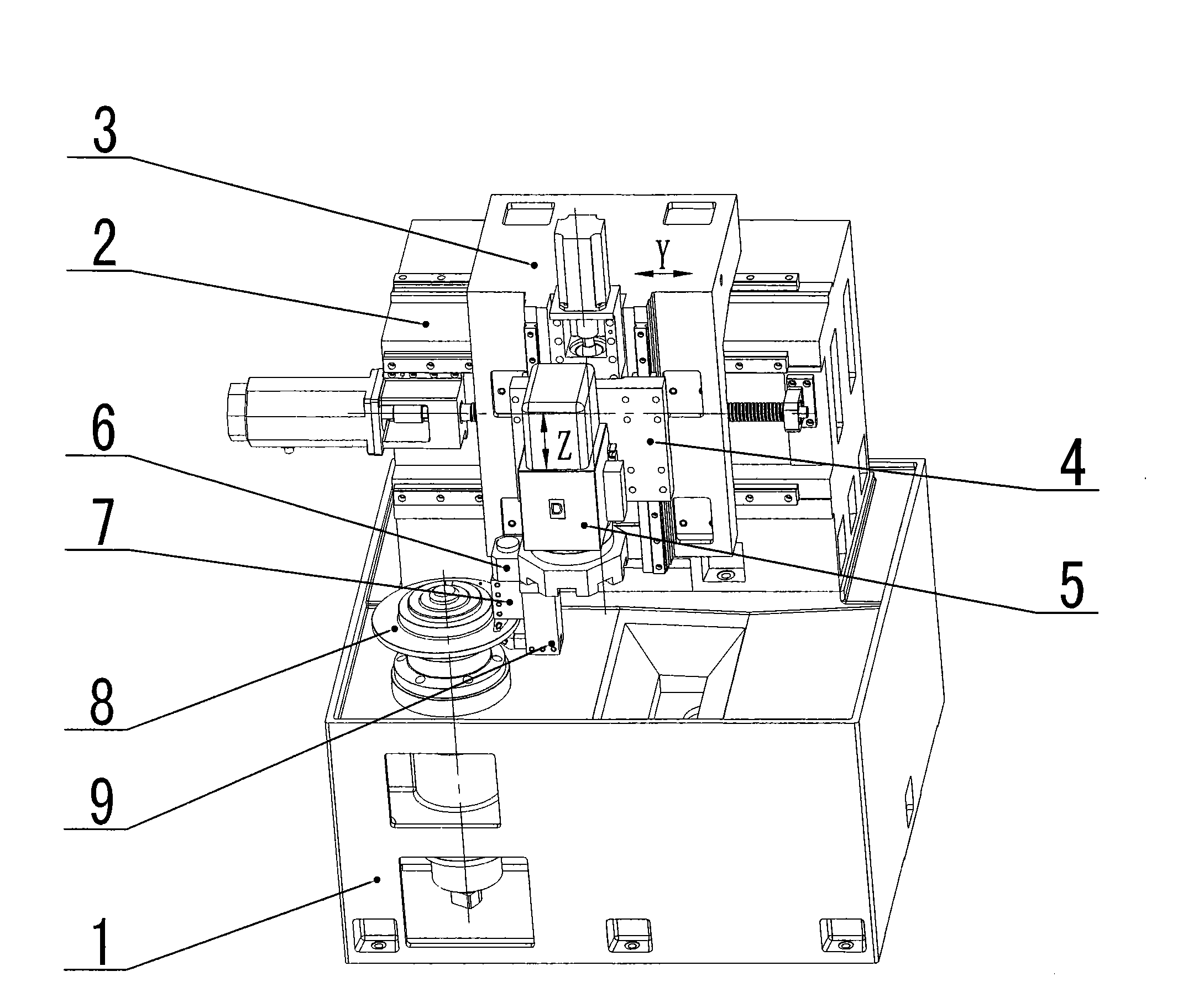

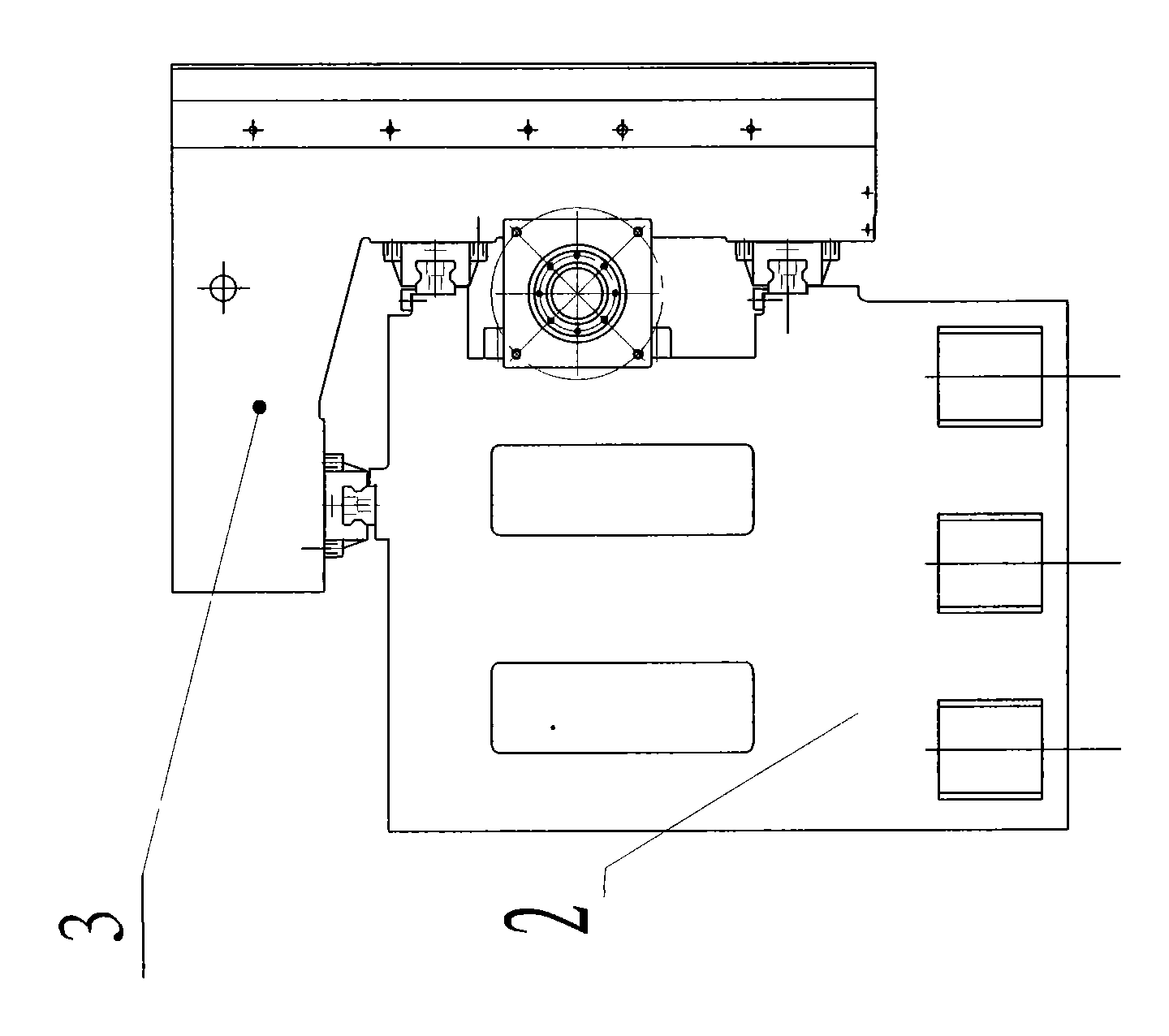

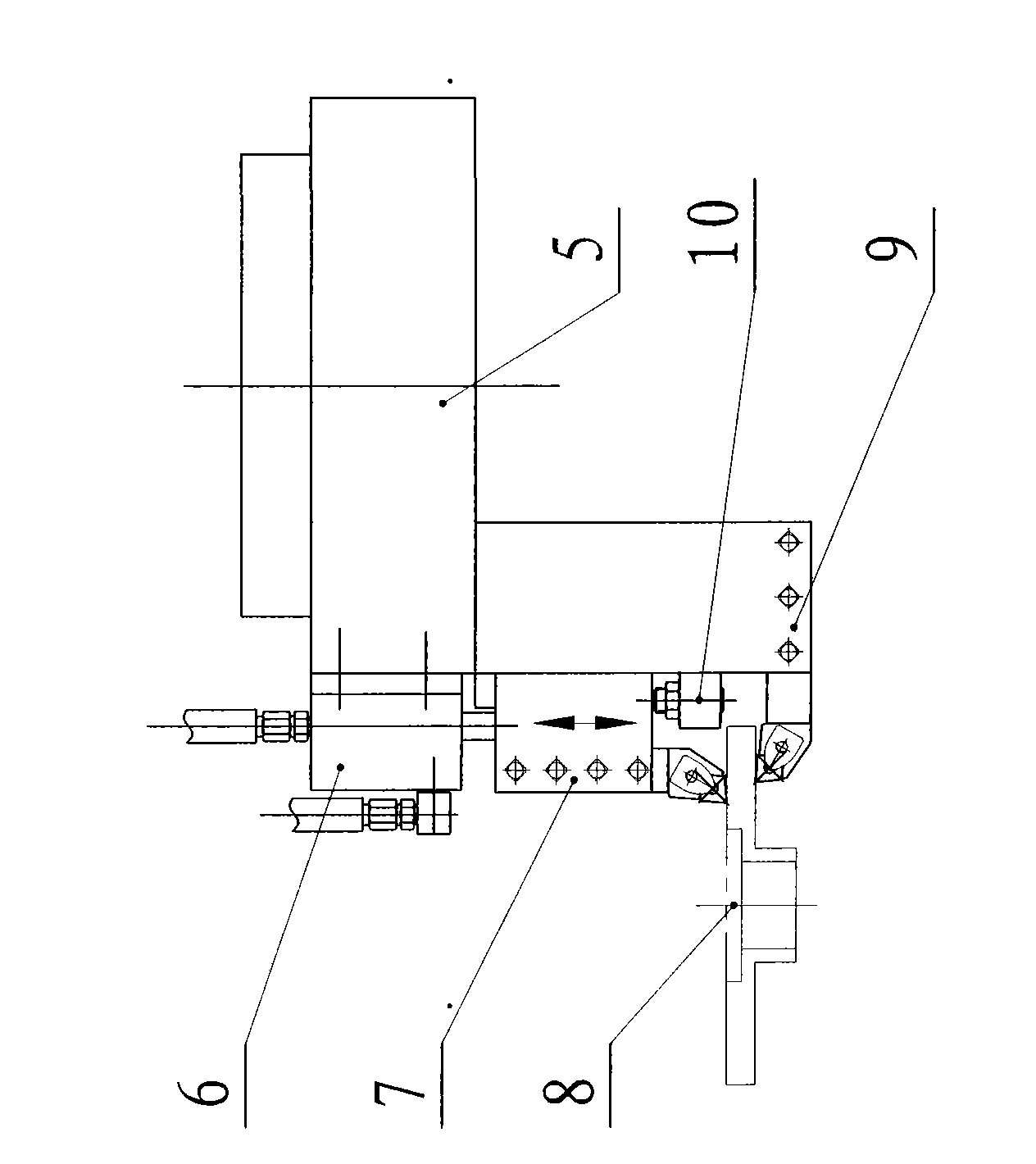

[0021] The method and structure of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 , image 3 As shown, the structure of the vertical lathe of the present invention includes a bed 1, a beam 2, a Y-axis curved plate saddle 3, a Z-axis saddle 4, and a turret 5; a tool rest 9 is arranged on the turret; There is a lower processing surface cutter 15, a positioning block 10 is arranged on the top of the tool rest, and a movable knife rest 7 is arranged above the positioning block 10; There is an upper processing surface cutter 14, and the top of the movable tool rest 7 is connected with the driving device 6. The driving device of the movable knife rest can adopt hydraulic mode, also can adopt the modes such as electric, mechanical, electromagnetic, as long as make the movable knife rest and positioning block can respectively guarantee to separate, close contact state all can reach the object of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com