Drilling method of rotary drilling machine in hard rock and special-purpose sediment pipe core cone bit

A technology for rotary drilling rigs and coring bits, which is applied in the directions of rotary drilling, rotary drilling rigs, drilling equipment and methods, etc., can solve the problems of extremely low strength of drilling tools, inability to eliminate high temperature, and limited drilling depth. , to achieve the effect of reducing construction cost, simple structure and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

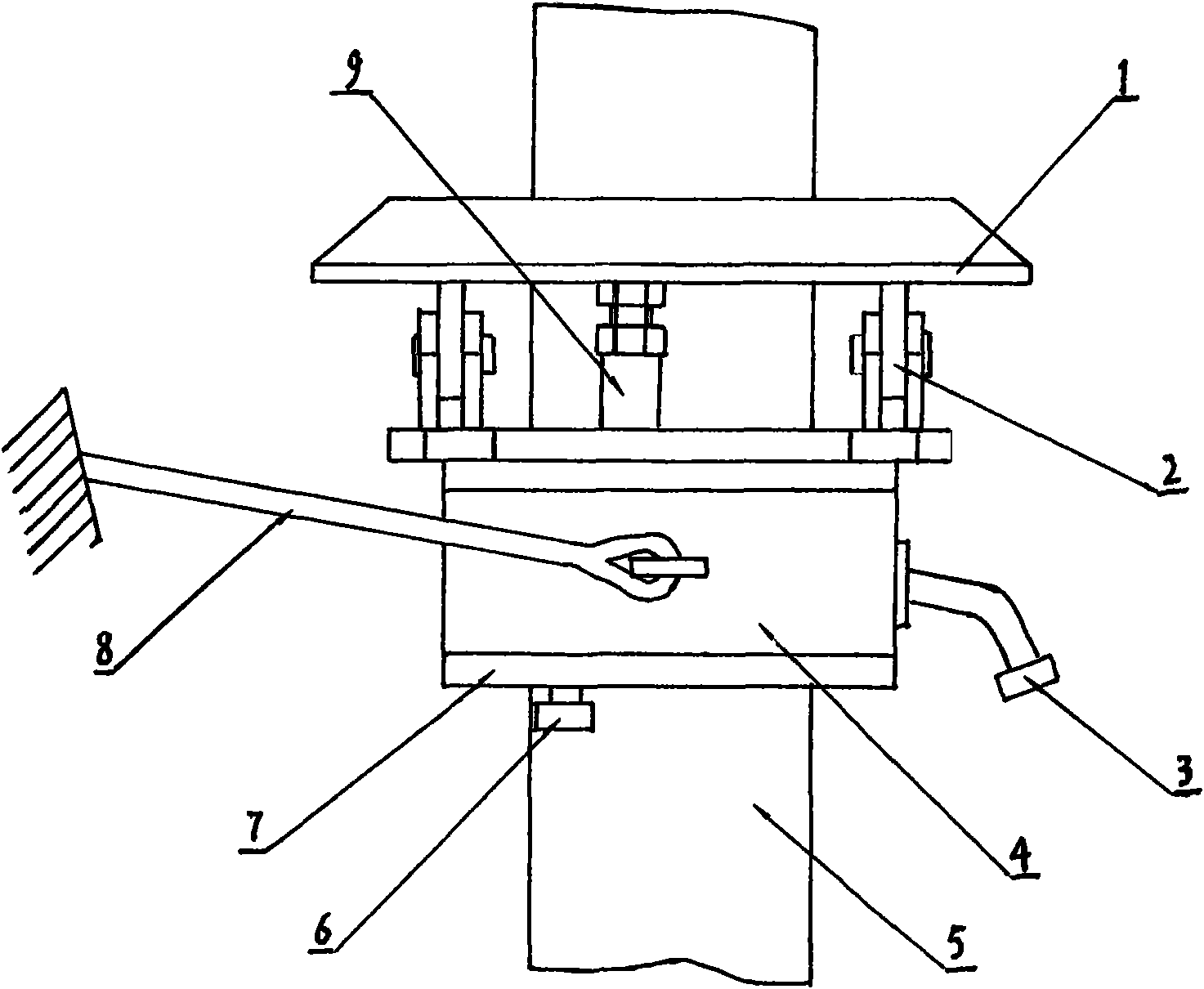

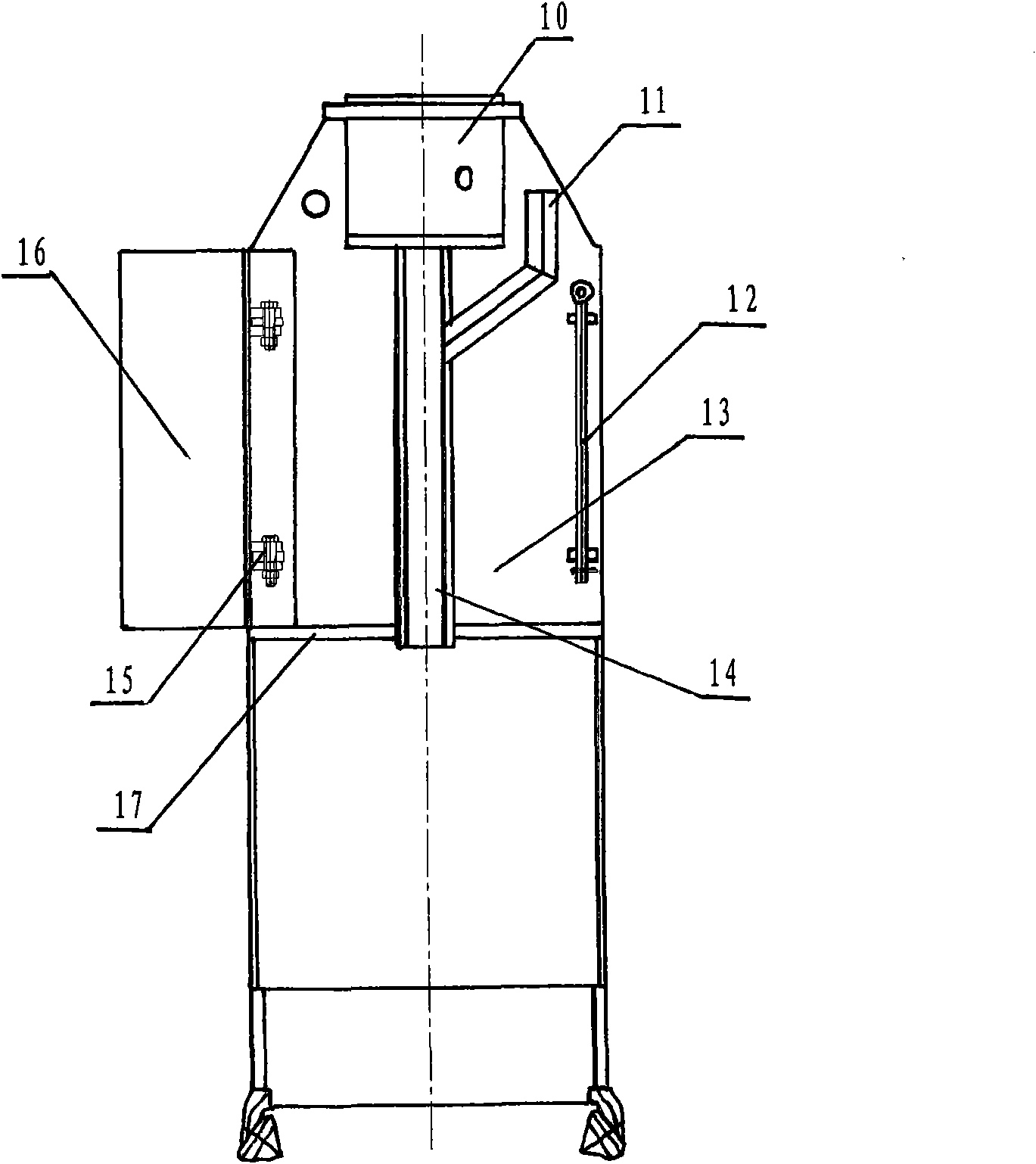

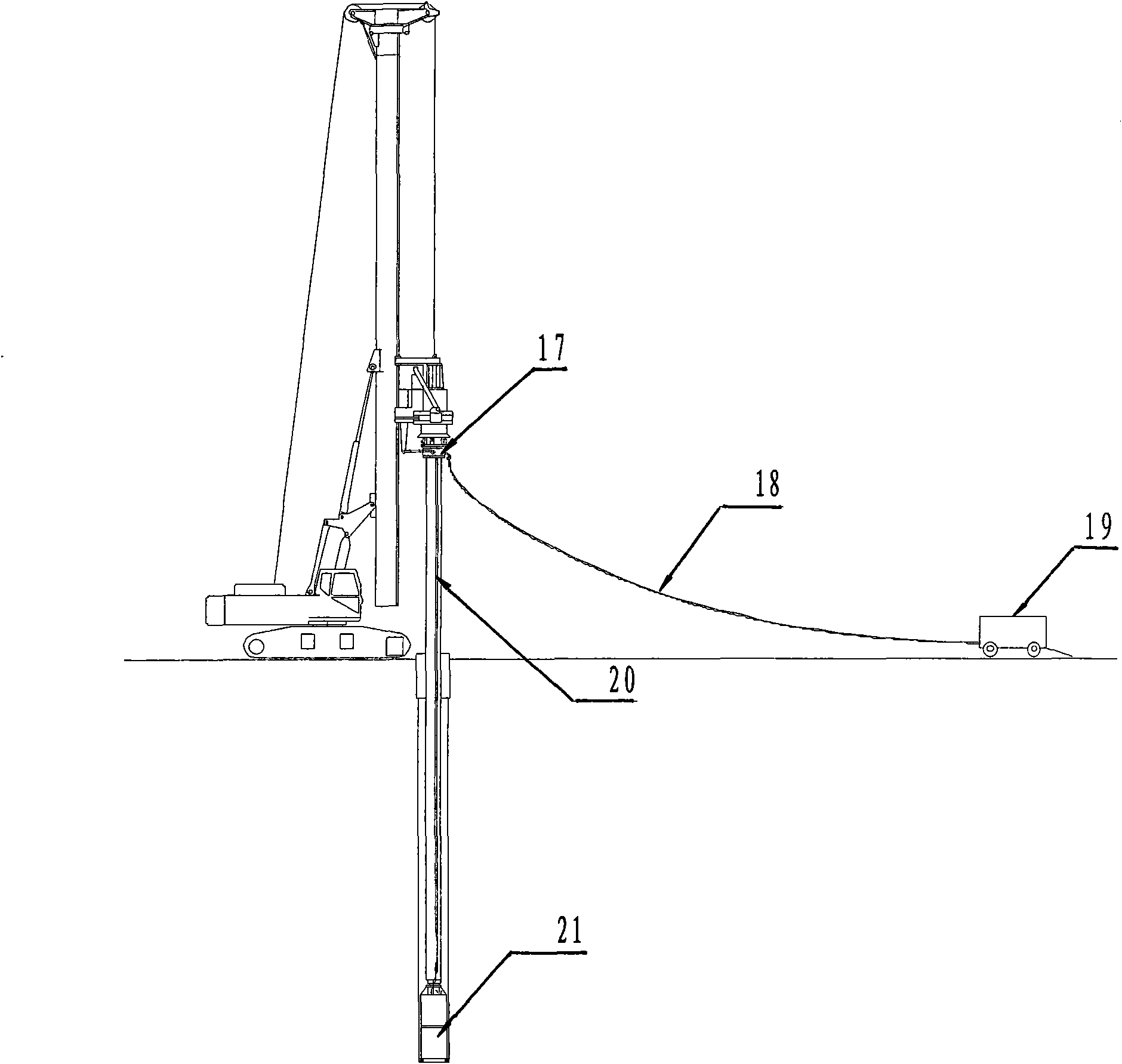

[0041] see figure 1 , figure 2 , image 3 , the drilling method of rotary drilling rig in hard rock comprises the following steps:

[0042] (1) Install the air-water joint 17

[0043] (2) Install sediment tube roller cone core bit 21

[0044] The installation method of the sediment tube roller cone core bit is the same as that of the common rotary drilling bit.

[0045] (3) Connect the air supply line, and put the drill bit into the bottom of the hole

[0046] a. Ground part: connect the air supply port of the air compressor 19 with the inlet 3 of the air-water joint with the ground hose 18;

[0047] b. Part in the hole: use the hose 20 in the hole to connect the outlet 6 of the air-water joint with the air supply pipe joint 11 of the sediment pipe cone core bit;

[0048] c. Put the drill bit into the bottom of the hole.

[0049] (4) Start the air compressor and send air into the hole. And start the rotary drilling rig to start drilling.

[0050] (5) After drilling, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com