Connection method for improving strength of overlap joints

A connection method and lap joint technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of reduced strength coefficient of aluminum alloy lap welded joints, large changes in welding parameters, slag inclusions and pores, etc. Achieve the effect of increasing the bearing area of the weld, increasing the bearing load, and changing the stress state of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

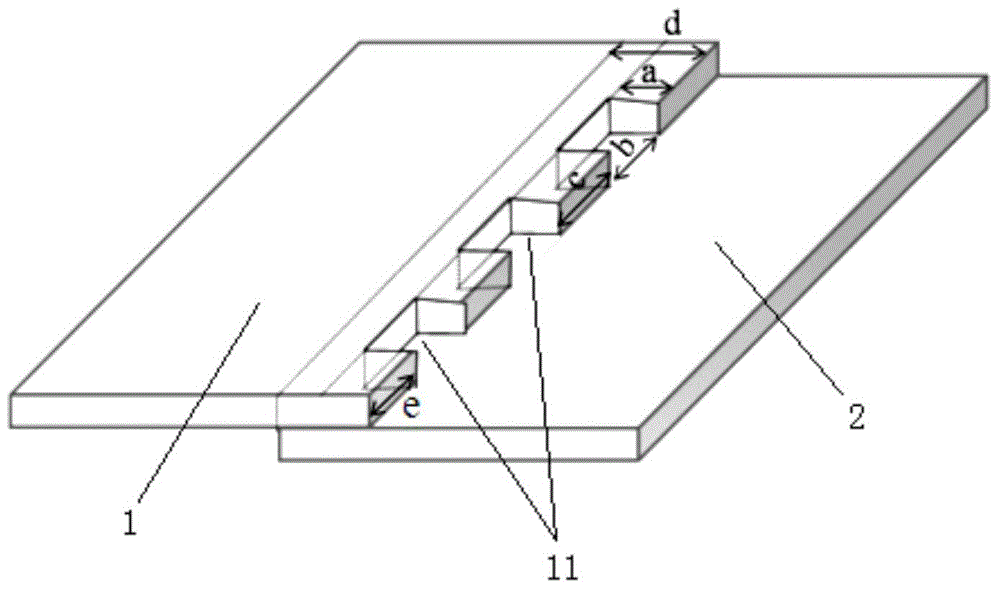

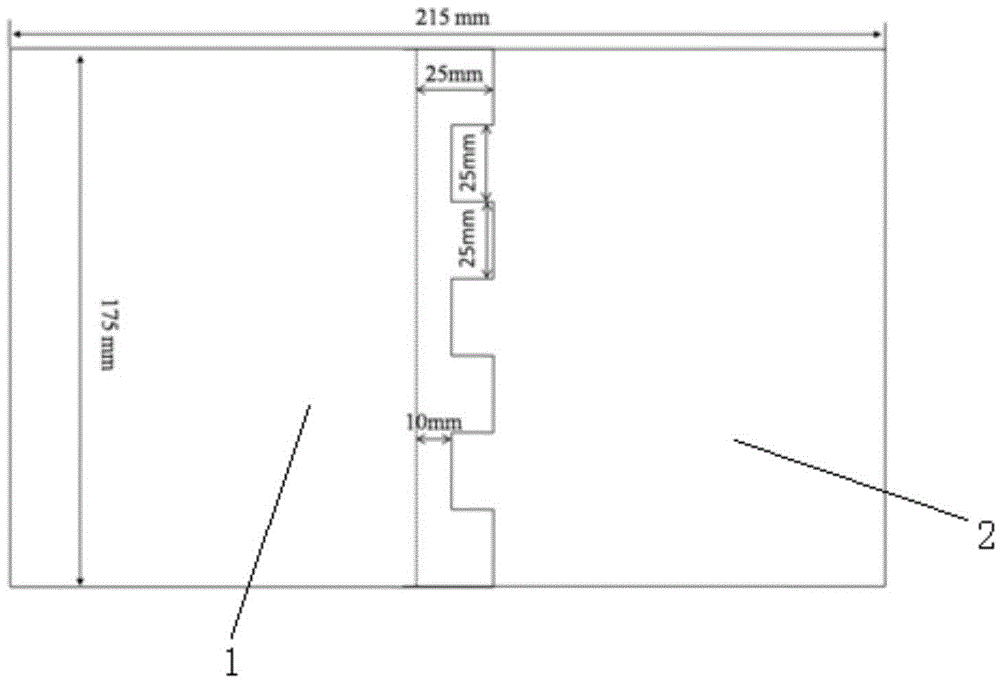

[0023] In this embodiment, the plate to be welded is A356 aluminum alloy, the size of the welded plate is 215mm×175mm×4mm, and the overlapping distance d is 25mm, as figure 2 shown. The metal inert gas shielded welding method is adopted, the filler material is ER4043 welding wire, the shielding gas is pure argon, the welding current is 130A, and the welding speed is 0.9m / min. Finally, the welding of the entire lap edge is completed by a robot.

[0024] In the first step, according to the overlapping distance d and the size of the overlapping plate, a plurality of rectangular notches 11 are processed on the overlapping edge of the overlapping upper plate 1 before welding, and processed into figure 1 , 2 In the sample shown, the number of processed rectangular notches 11 is 3, of which figure 2 The dimensions indicated are not intended to be limiting. Specifically: the width a of the rectangular notch 11 is 15mm, the length b of the rectangular notch 11 is 25mm, the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com