Bottoming welding method of laser-hot wire MIG composite based on light beam scanning

A welding method and beam scanning technology, which is applied in the field of laser-hot wire MIG composite backing welding, can solve the problem that the back of the liquid metal weld is easy to form concaves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

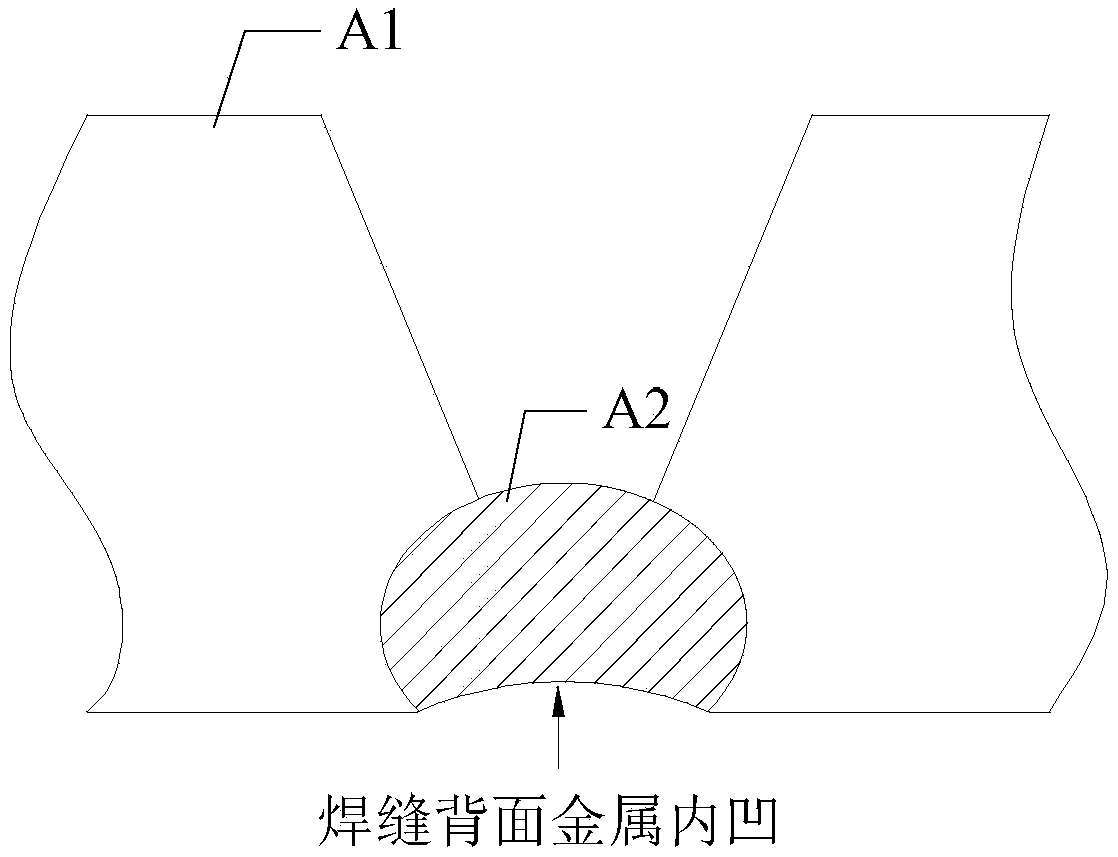

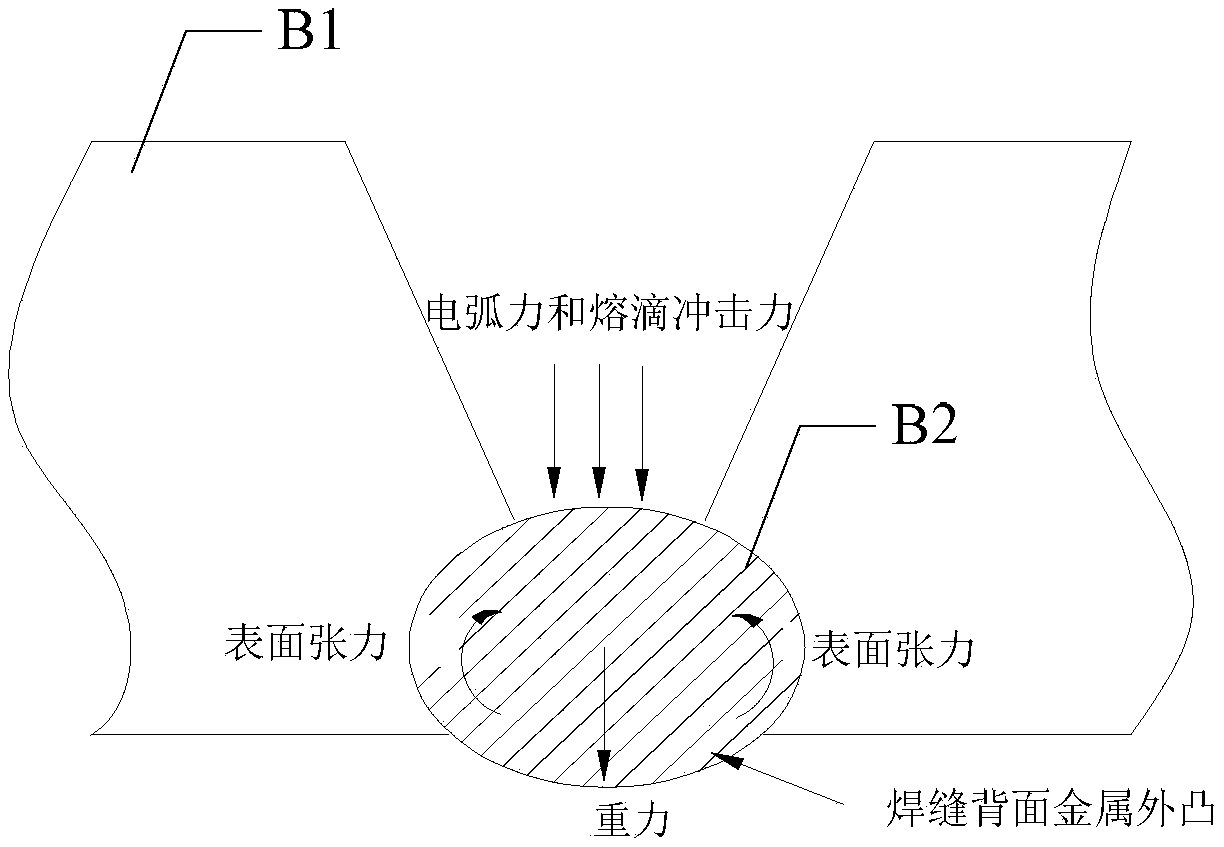

[0019] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment mode, a laser-hot wire MIG composite bottoming welding method based on beam scanning described in this embodiment, the bottoming welding method includes: a laser beam scanned along a certain trajectory and a hot wire protected by an inert gas MIG arc combination is used for backing welding. The laser beam and arc act in a welding pool. By reasonably matching the power of the laser beam, scanning frequency, and laser swing, it can stir the welding pool to a certain extent and change the welding pool. The stressed state of the pool, thus completing the root welding of the workpiece to be welded.

[0020] In this embodiment, the laser beam scanning technology is used to stir the welding pool of the workpiece to be welded, changing the hand state of the welding pool and reducing the resistance of the liquid metal to the root of the groove , improve the forming effect of the back of t...

specific Embodiment approach 2

[0021] Specific embodiment 2: This embodiment is a laser-hot wire MIG composite bottoming welding method based on beam scanning described in specific embodiment 1. In this embodiment, the laser beam and the MIG arc are compounded. For: paraxial compound mode;

[0022] The paraxial composite method is specifically: the laser beam is in front, the MIG arc is behind, the inclination angle of the laser beam is controlled between 80° and 90°, the inclination angle of the MIG arc welding torch is controlled between 55° and 65°, and the light The wire pitch is 0mm to 8mm.

specific Embodiment approach 3

[0023] Specific embodiment three: This embodiment is a laser-hot wire MIG composite welding method based on beam scanning described in specific embodiment one. In this embodiment, the shape of the scanning trajectory of the laser beam is circular, One of elliptical, S-shaped or zigzag, the scanning frequency F of the laser beam is greater than or equal to 100HZ, and the scanning width B of the laser beam is in the range of 2mm-5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Defocus amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com