High-tenacity less-splashing self-shielded coated flux-cored welding wire and preparation method thereof

A technology of flux-cored welding wire and self-protection, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of unstable arc, high spatter rate, uneven coating, etc., and achieve the effect of small spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

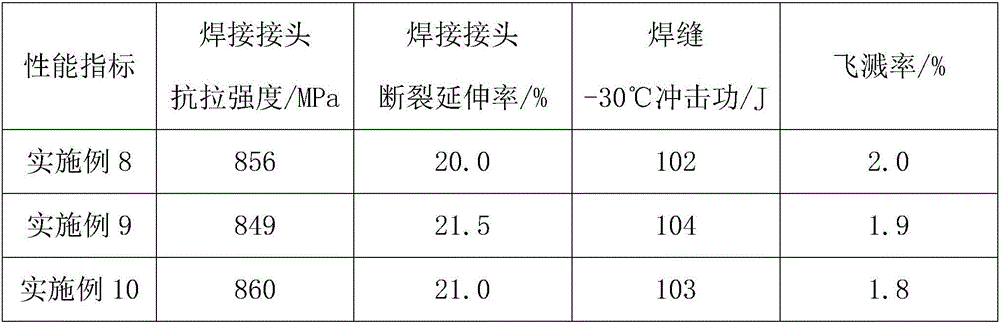

Examples

Embodiment 1

[0055] A high-toughness spatter-less self-protective coating flux-cored welding wire, including a wire base and a coating coated on the surface of the wire base, wherein the wire base is composed of a low-carbon steel sheath and a flux core filled in the low-carbon steel sheath; wherein The drug core raw materials include by weight percentage: 15% rutile, 1% ferroniobium, 1% aluminum powder, 1% magnesium powder, 6% fluoride, 0.5% magnesia, 0.5% zircon sand, and 65% iron powder; , F / (Mg+Al)=0.05, Mg is that magnesium powder is converted into magnesium content and accounts for the weight percent of drug core material; Al is aluminum powder is converted into aluminum content and accounts for the weight percent of drug core material, and F is that fluoride is converted into fluorine The content accounts for the weight percentage of the drug core raw material.

Embodiment 2

[0057] A high-toughness spatter-less self-protective coating flux-cored welding wire, including a wire base and a coating coated on the surface of the wire base, wherein the wire base is composed of a low-carbon steel sheath and a flux core filled in the low-carbon steel sheath; wherein The drug core raw materials include by weight percentage: 23% rutile, 2% ferroniobium, 3% aluminum powder, 2% magnesium powder, 10% fluorite, 1% magnesia, 0.9% zircon sand, and 58.1% iron powder; , F / (Mg+Al)=0.035, Mg is that magnesium powder is converted into magnesium content and accounts for the weight percent of drug core material; Al is aluminum powder is converted into aluminum content and accounts for the weight percent of drug core material, and F is that fluoride is converted into fluorine The content accounts for the weight percentage of the drug core raw material.

Embodiment 3

[0059] A high-toughness spatter-less self-protective coating flux-cored welding wire, including a wire base and a coating coated on the surface of the wire base, wherein the wire base is composed of a low-carbon steel sheath and a flux core filled in the low-carbon steel sheath; wherein , The raw materials of the drug core include by weight percentage: 30% rutile, 1.5% ferroniobium, 2% aluminum powder, 1.5% magnesium powder, 4% sodium fluorosilicate, 4% barium fluoride, 0.75% magnesia, 0.75% zircon sand %, iron powder 55.5%; wherein, F / (Mg+Al)=0.039, Mg is the percentage by weight of magnesium powder converted into magnesium content in drug core raw materials; Al is the weight percentage of aluminum powder converted into aluminum content in drug core raw materials , F is the percentage by weight of fluoride converted into fluorine content of the drug core raw material; the surface coating raw material includes by weight percentage: graphite 5%, lithium carbonate 15%, potassium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com