Self-hydraulic automatic regulation valve

An automatic regulating valve, hydraulic technology, applied in the field of automatic regulating valve, self-hydraulic, can solve the problem of inability to realize automatic adjustment and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

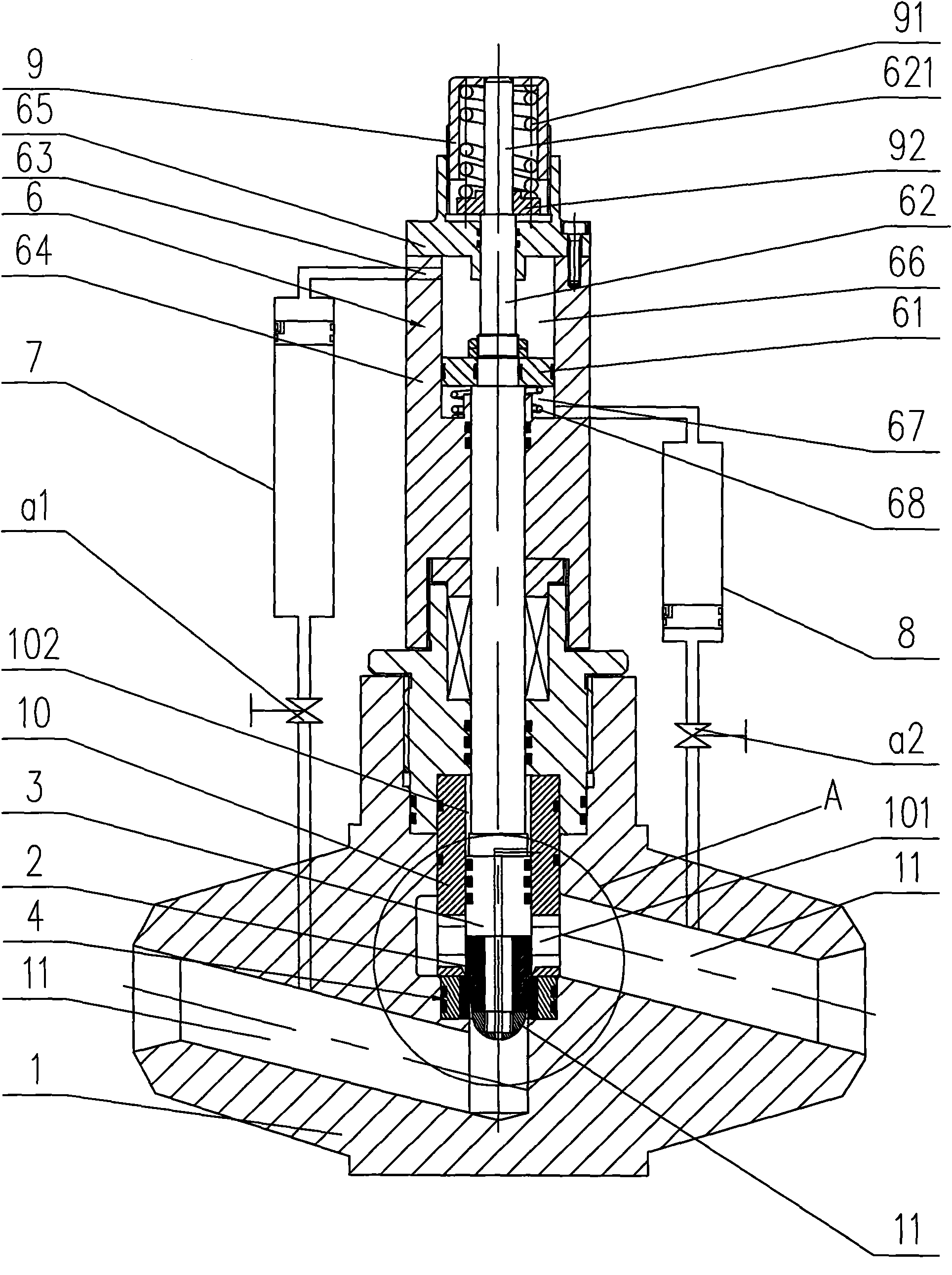

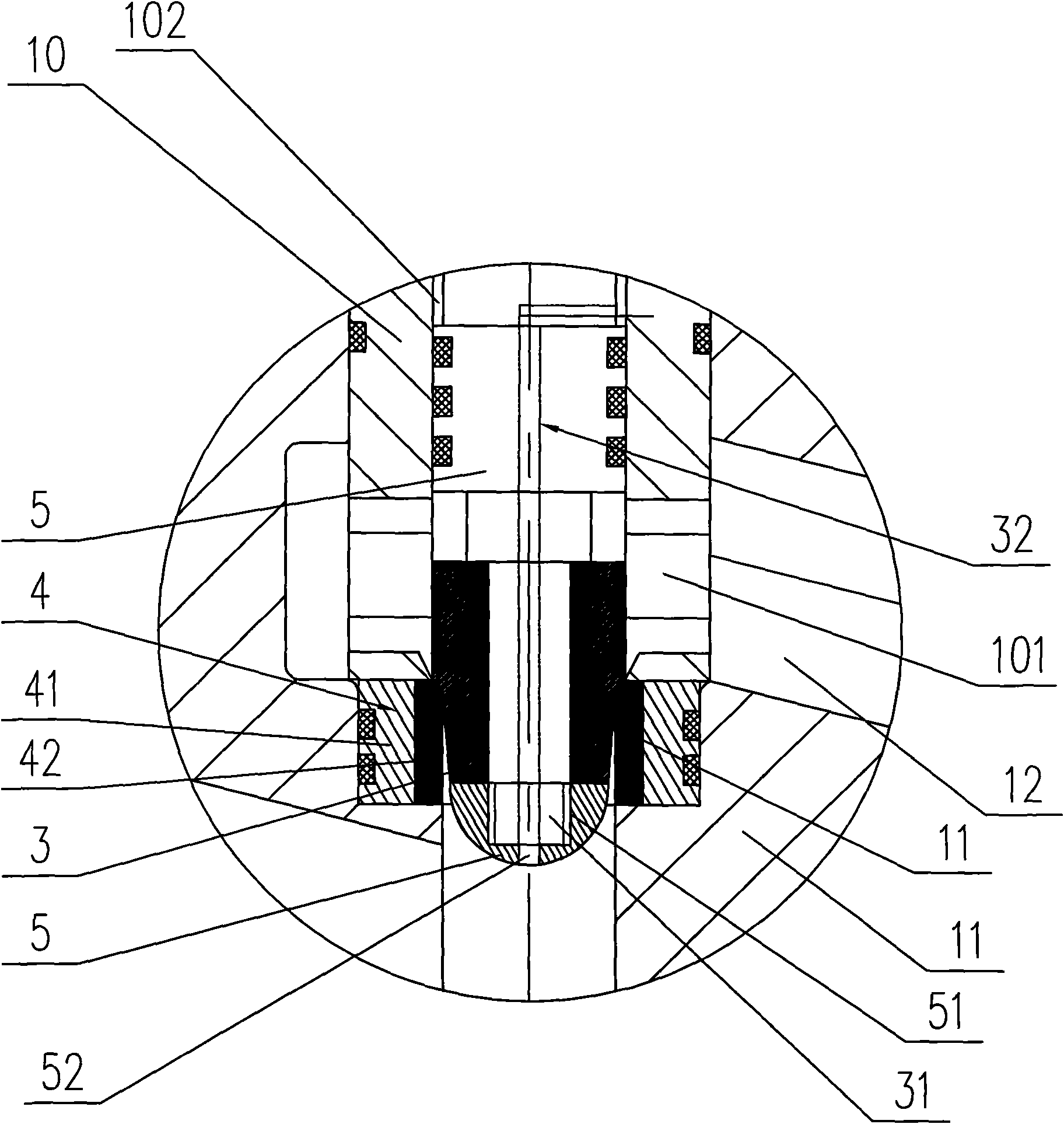

[0014] Such as figure 1 As shown, the specific embodiment of the present invention is a self-hydraulic, automatic regulating valve, including valve body 1, regulating head 2, regulating head fastener 5, main hydraulic cylinder 6, inlet hydraulic cylinder 7, outlet hydraulic cylinder 8, The valve stem 3 and the valve seat 4, wherein the valve body 1 is provided with two flow channels with different heights and heights, the water inlet flow channel 11 is set at the lower place, and the water outlet flow channel 12 is set at the higher place, and the two are connected through the middle flow channel . The valve seat 4 is arranged at the middle flow channel, and the regulating head 2 is set to form a sealing pair with the valve seat 4, and the mating surfaces of the regulating head 2 and the valve seat 4 are provided with slopes to form a sealing fit of the slopes. A main hydraulic cylinder 6 is arranged at the upper end of the valve rod 3, and the upper end of the valve rod 3 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com