High-purity metformin hydrochloride preparation method

A kind of metformin hydrochloride, production method technology, applied in the field of pharmaceutical chemical synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

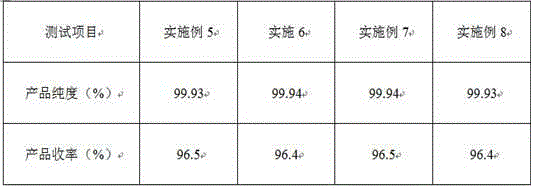

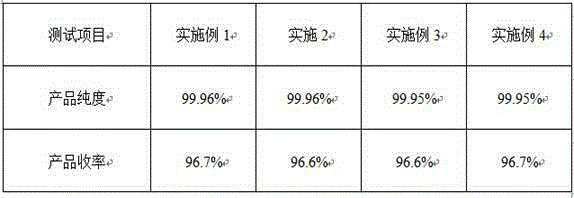

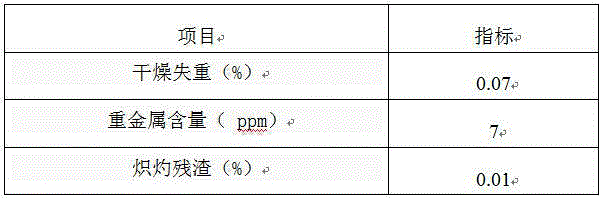

Examples

Embodiment 1

[0049] 2. Stir

[0050] (1) Stirring for the first time

[0051] Open the steam valve, turn on the steam to raise the temperature, and use a frequency converter to adjust the stirring speed to 50-60 rpm.

[0052] (2) Second heating

[0053] Stir for 15-20 minutes to raise the temperature of the synthesis kettle to 62°C.

[0054] (3) Adjust the vacuum degree for the first time

[0055] Turn on the vacuum pump, adjust the vacuum degree in the synthesis kettle to 0.04MPa, and continue stirring for 10-20 minutes after the vacuum degree is stable.

[0056] (4) Three heating times

[0057] Open the large steam valve, continue to heat up, and stir for 15-20 minutes to raise the temperature of the synthesis kettle to 75°C.

[0058] (5) Secondary adjustment of vacuum degree

[0059] Adjust the vacuum degree in the synthesis kettle to be 0.06MPa.

[0060] (6) Secondary stirring

[0061] After the vacuum degree is stable, the stirring speed is adjusted to 80 rpm, and the stirring...

Embodiment 2

[0095] Using the preparation steps of Example 1, the solvent used is the mother liquor produced in the spin-drying step of Example 2, which is put into a centrifuge from the synthesis kettle and continued to be reused to prepare metformin hydrochloride.

Embodiment 3

[0097] Solvent and solute are added into the synthesis kettle step, the solvent used is the mother liquor produced in the drying step of Example 3, put into the centrifuge from the synthesis kettle, continue to reuse, and add 100Kg of N-methylpyrrolidone and suck it into the synthesis kettle. Metformin hydrochloride was prepared according to the method of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com