Gluing thickness online detection device in gluing production line

A technology of glue coating thickness and detection device, which is applied in the direction of surface coating liquid device, measuring device, optical device, etc., can solve the problems of affecting the lamination process, prolonging the standby time of equipment, and troublesome operation procedures, etc., to achieve the guarantee Accuracy and stability, simple and reliable detection process, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, so that those skilled in the art can implement it with reference to the description.

[0025] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

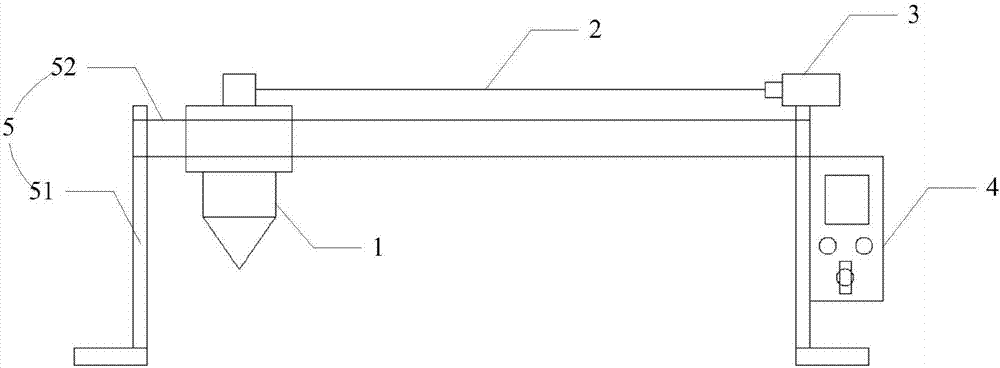

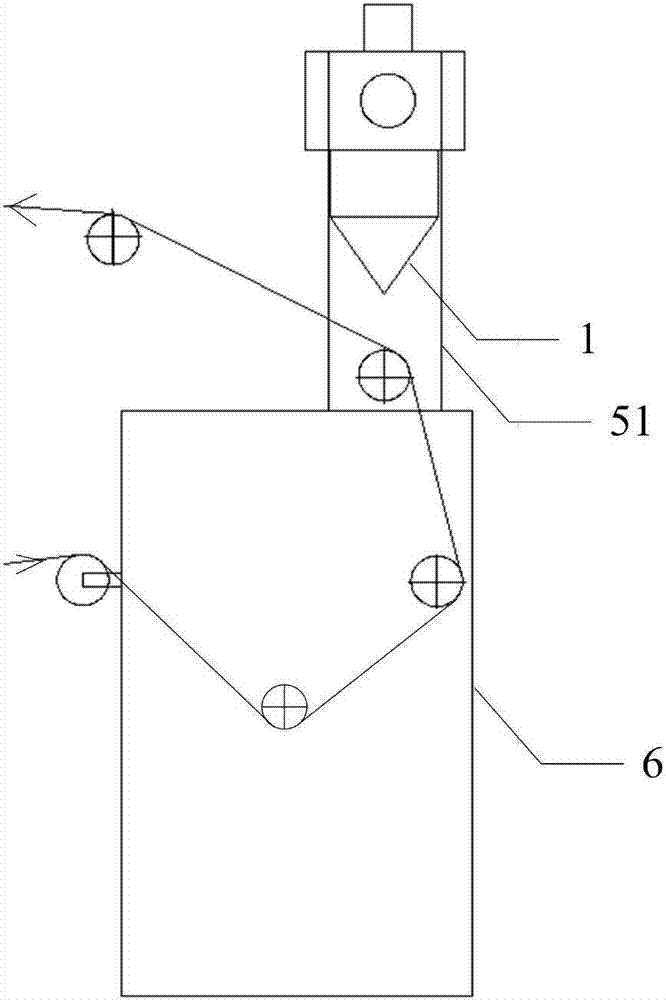

[0026] Such as figure 1 and figure 2 As shown, the present invention provides a kind of gluing thickness online detection device in gluing production line, and it is fixed on the gluing coating head mechanism, comprises:

[0027] Glue thickness detection mechanism 1, which is selected as infrared detection head in this embodiment; screw shaft 2; drive mechanism 3, which is selected as telescopic motor in this embodiment; control mechanism 4 with data display and control interface; frame main body 5, The frame main body 5 includes two vertical fixed arms 51 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com