Single-screw-rod co-extrusion machine for machining section material

A single-screw and profile technology, applied in the field of single-screw co-extruders, can solve the problems of plastic dispersion, plasticization, unstable extrusion and unevenness, etc., and achieve stable extrusion, good plasticizing effect, and lower electricity costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

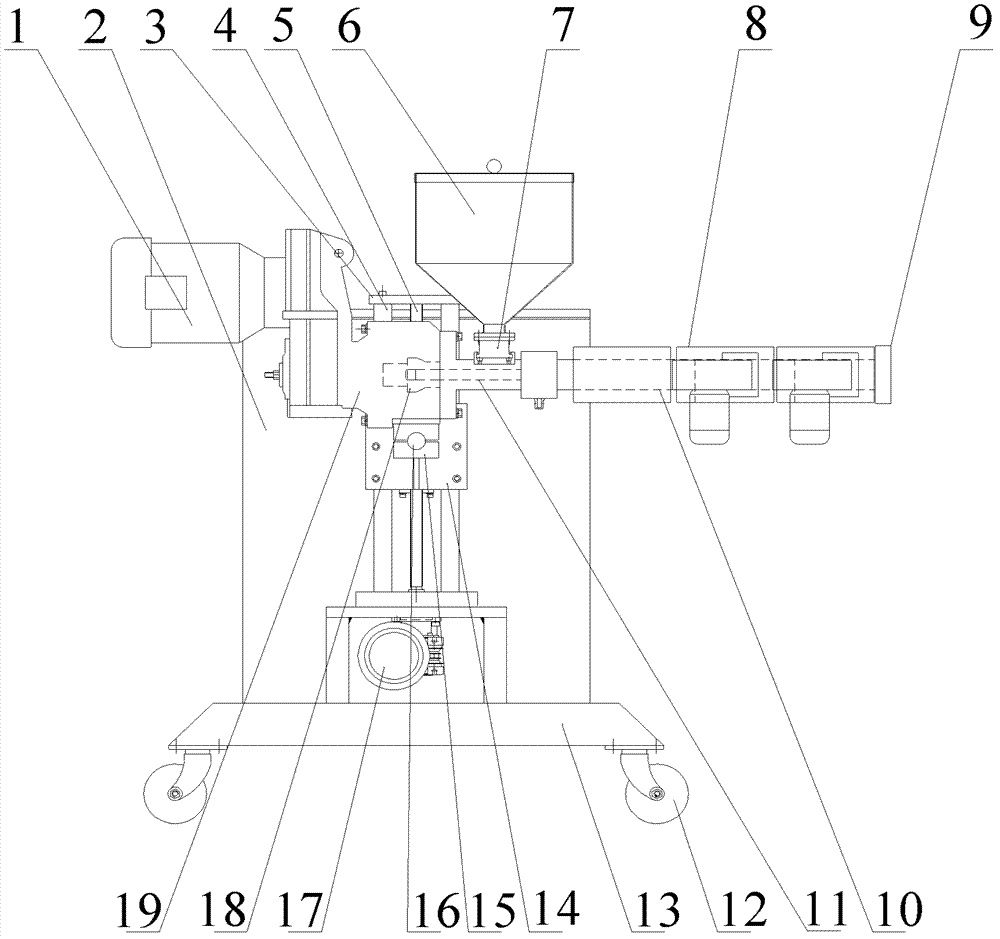

[0028] A single-screw co-extrusion machine for processing profiles, its structure is as follows figure 1 As shown, it includes an extruding mechanism, a feeding mechanism, a driving mechanism, an up and down moving mechanism, a front, back, left and right moving mechanism and an electric control box 2. Among them, the extrusion mechanism includes a screw 11, a barrel 10, a heater and a cooling fan 8, and a hopper connecting seat 7. The screw 11 and the barrel 10 are socketed to form a material channel, and the heater and the cooling fan 8 are arranged on the barrel 10. The front end of the machine barrel 10 is also equipped with a machine head flange 9 , and the hopper connecting seat 7 is connected to the rear end of the machine barrel 10 . Feeding mechanism is made up of hopper 6 and hopper cover, and hopper 6 is connected on the hopper connecting seat 7, and hopper cover is located at the top of hopper 6. The driving mechanism includes a connecting shaft 18, a motor connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com