Method for manufacturing nylon/spandex air-textured yarn by false twist texturing machine one-step method

A technology of false twist texturing machine and air-wrapped yarn, which is applied in the direction of textiles, papermaking, yarn, etc., can solve the problems of management cost, high storage site and production organization cost, and large workshop area occupancy rate, so as to broaden the scope of spinning, Reduce the waste of raw materials and avoid the effect of monofilament winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

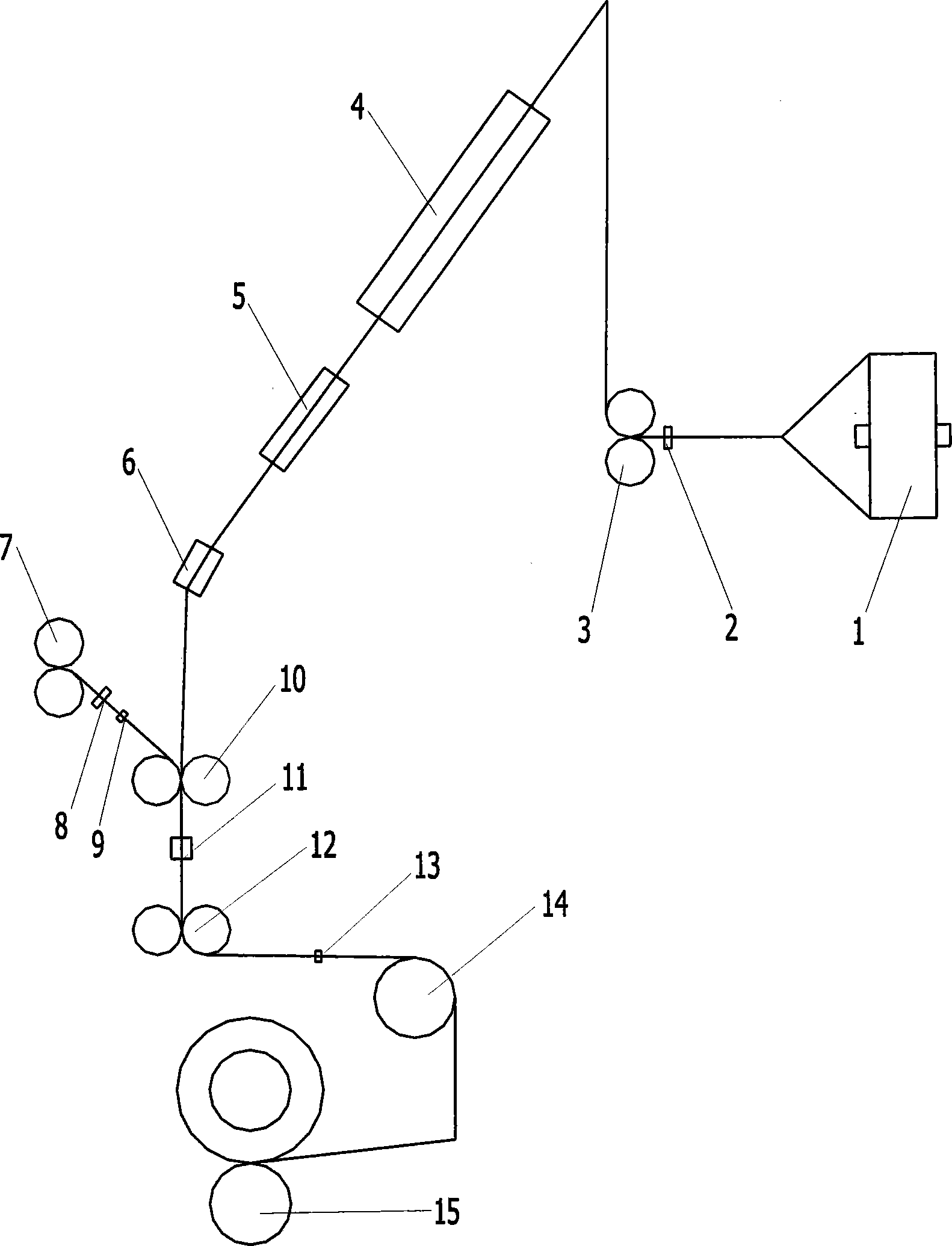

[0017] The present invention uses a nylon false-twist texturing machine to carry out a one-step method for producing nylon and spandex empty covered yarn. A set of spandex roller device 7, a second thread cutter 8, and a second thread detector are installed on the original nylon machine. The device 9, the network device 11, the intermediate auxiliary roller (W2x) and the thread transfer device 10 for doubling are placed in a relatively reasonable position on the nylon false twister through the connecting piece to ensure the optimization of the silk path. The method includes the following steps:

[0018] A) The polyamide yarn (POY) is led out from the original yarn frame 1, and enters the first feeding roller 3 through the first thread cutter 2 on the false twist texturing machine, and is heated by the deformation hot box 4, and then enters the cooling device 5 and false The twister 6 (including the thread guide) is led out and sucked by a sniffer.

[0019] B) The spandex thread is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com