A method for controlling the coplanarity of the guide wheels in the winding and arranging link of a multi-wire slicer

A wire slicing and wire arranging wheel technology, applied in the direction of manufacturing tools, fine working devices, stone processing equipment, etc., can solve the problems of reduced cutting quality, increased additional tension of diamond wire, reduced cutting ability, etc., to reduce the additional tension. , avoid accumulating torsion, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with preferred embodiments.

[0018] Multi-wire cutting is a cutting process that cuts hard and brittle materials into thousands of thin slices at a time through high-speed reciprocating motion of diamond wires. Diamond wire as a cutting tool needs a certain tension during processing, so in the slicer, the diamond wire passes through the mechanical transmission link to the take-up end after it exits from the pay-off end, and the diamond wire is in a tensioned state during the process of passing through the transmission link.

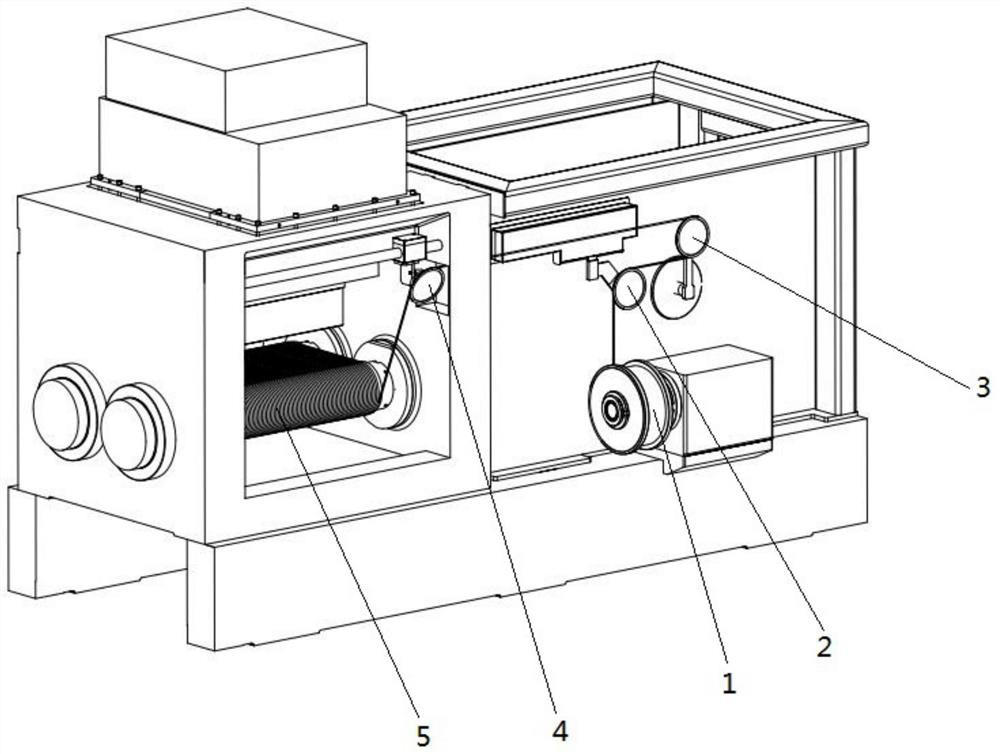

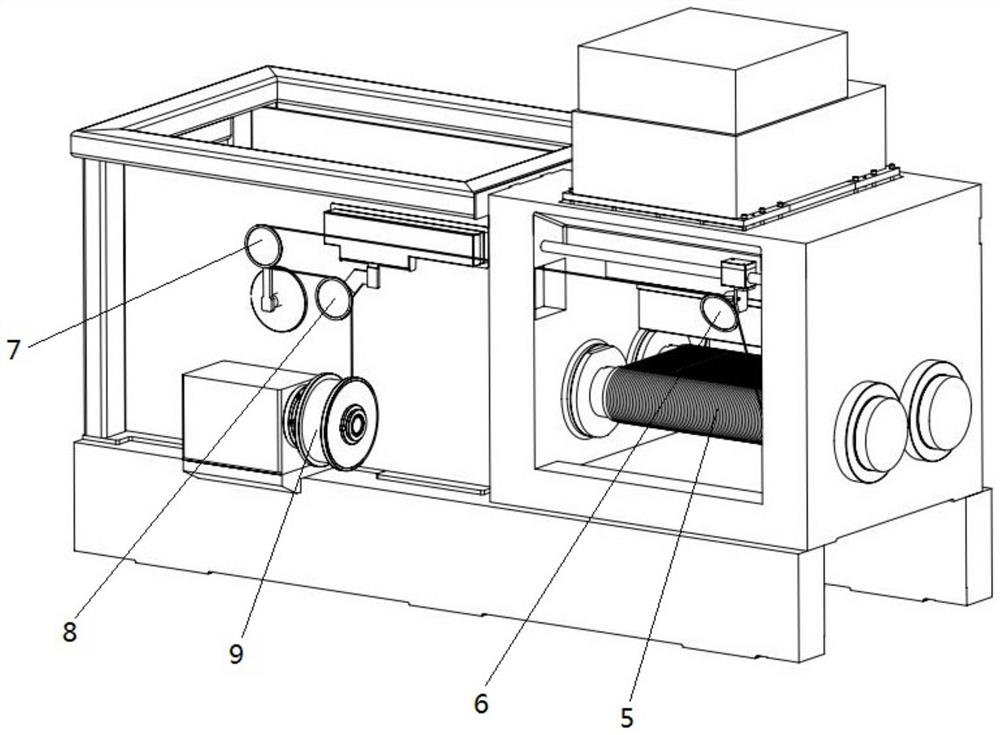

[0019] There are several guide wheels in the above transmission link, see figure 1 and figure 2 , wherein the guide wheels involved include a wire feed roller 1, a wire pulley I2, a tension pulley I3, a guide pulley I4, a guide pulley II6, a tension pulley II7, a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com