Curing kiln of light aggregate concrete hollow partition board

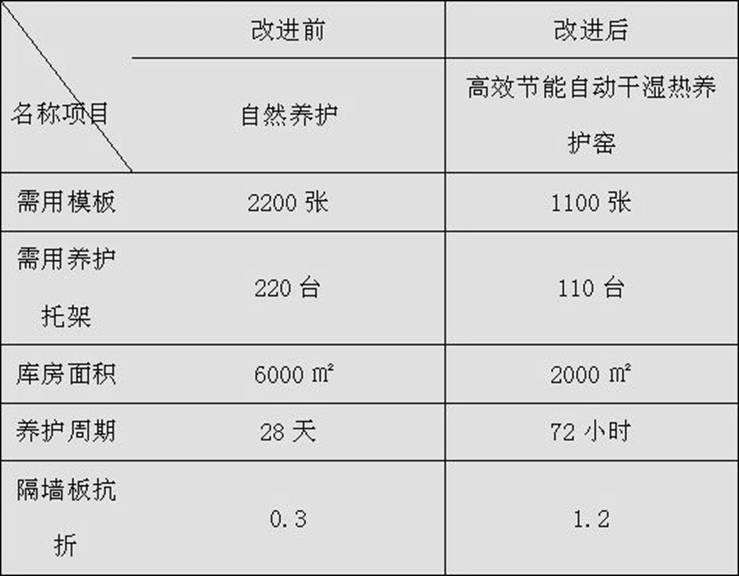

A light aggregate concrete and partition wall panel technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve problems such as heat loss, leakage, and impact on product quality, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

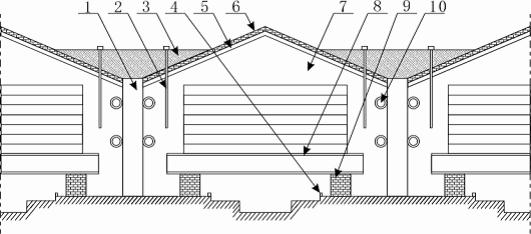

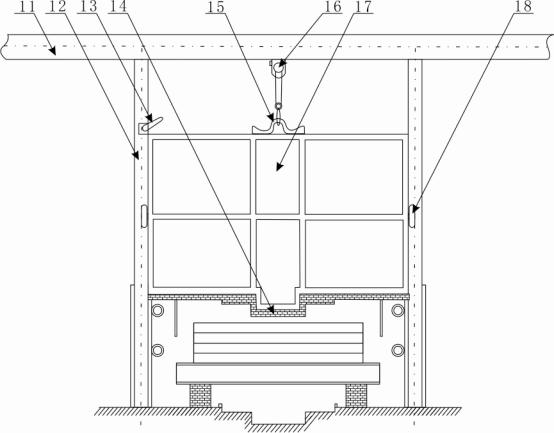

[0018] -Such as figure 1 and figure 2 As shown, the light aggregate concrete hollow partition board maintenance kiln is composed of the kiln back wall 7, the kiln roof 5, the kiln door 17 and the insulation partition wall 1 which are closely connected together; the kiln roof 5 is a "person" Glyph structure, the top of the kiln roof 5 is at an angle of 150°; the adjacent kiln bodies are separated by the insulation partition wall 1; the rear end of the insulation partition wall 1 is closely connected with the kiln rear wall 7, and the front end of the insulation partition wall 1 is provided Kiln door column 12; the upper end of the kiln door column 12 is provided with a kiln door beam 11; the lowest point of the kiln roof 5 is closely connected with the insulation partition wall 1; the kiln roof 5 is covered with a kiln roof insulation la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com