Preheating powder spreading device for selective laser melting metal 3D printing

A laser selective melting, 3D printing technology, applied in the direction of improving process efficiency, improving energy efficiency, additive manufacturing, etc., can solve the problems of complex powder spreading operation, low tiling efficiency, high energy consumption, etc., to save heating and melting. Time, high tiling efficiency, uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

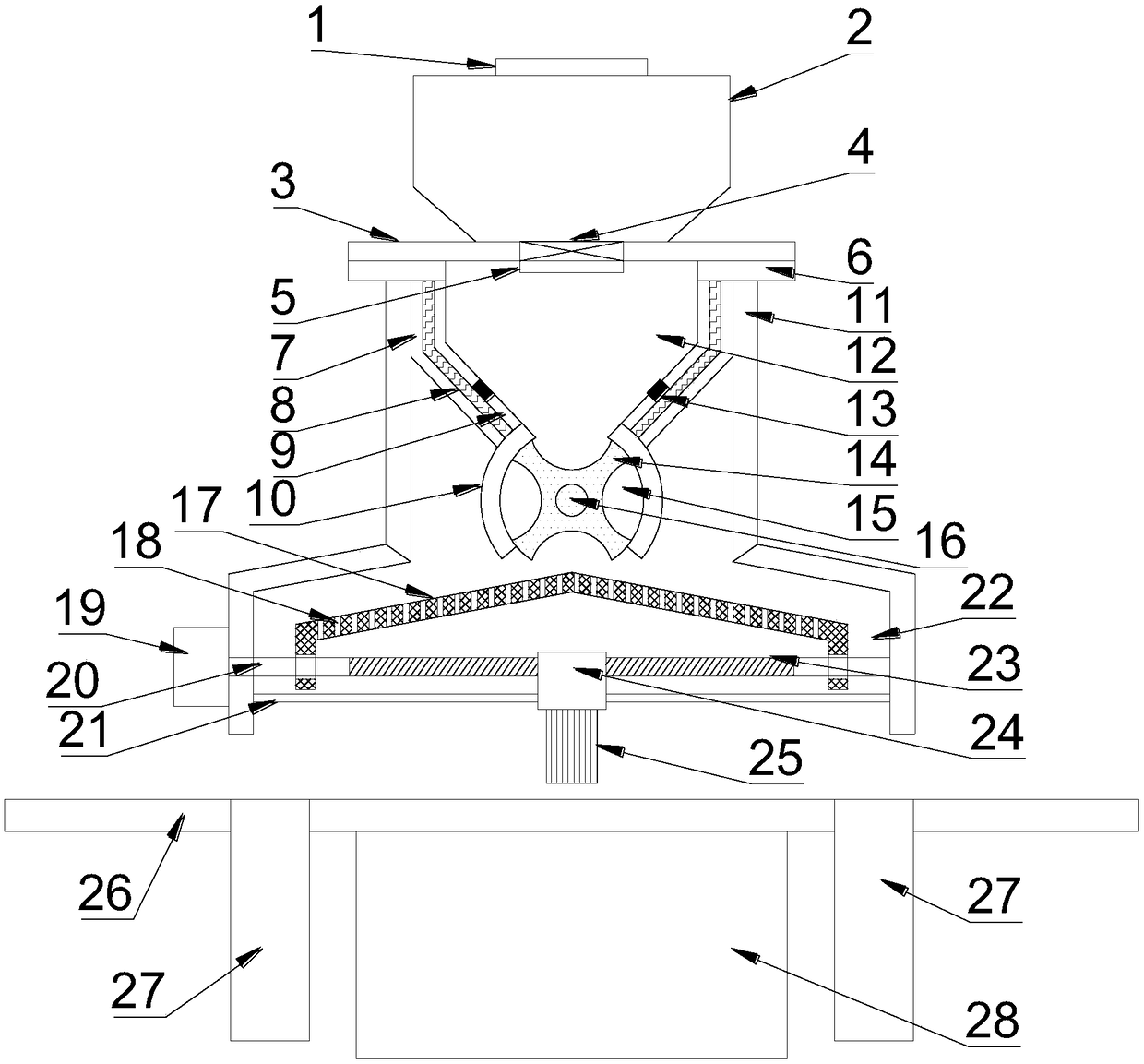

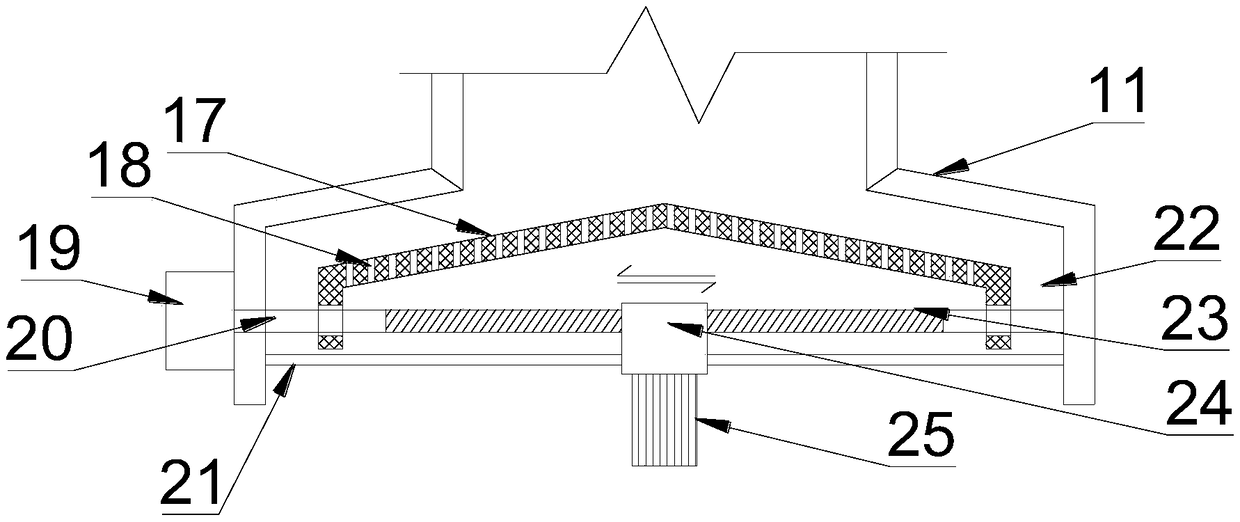

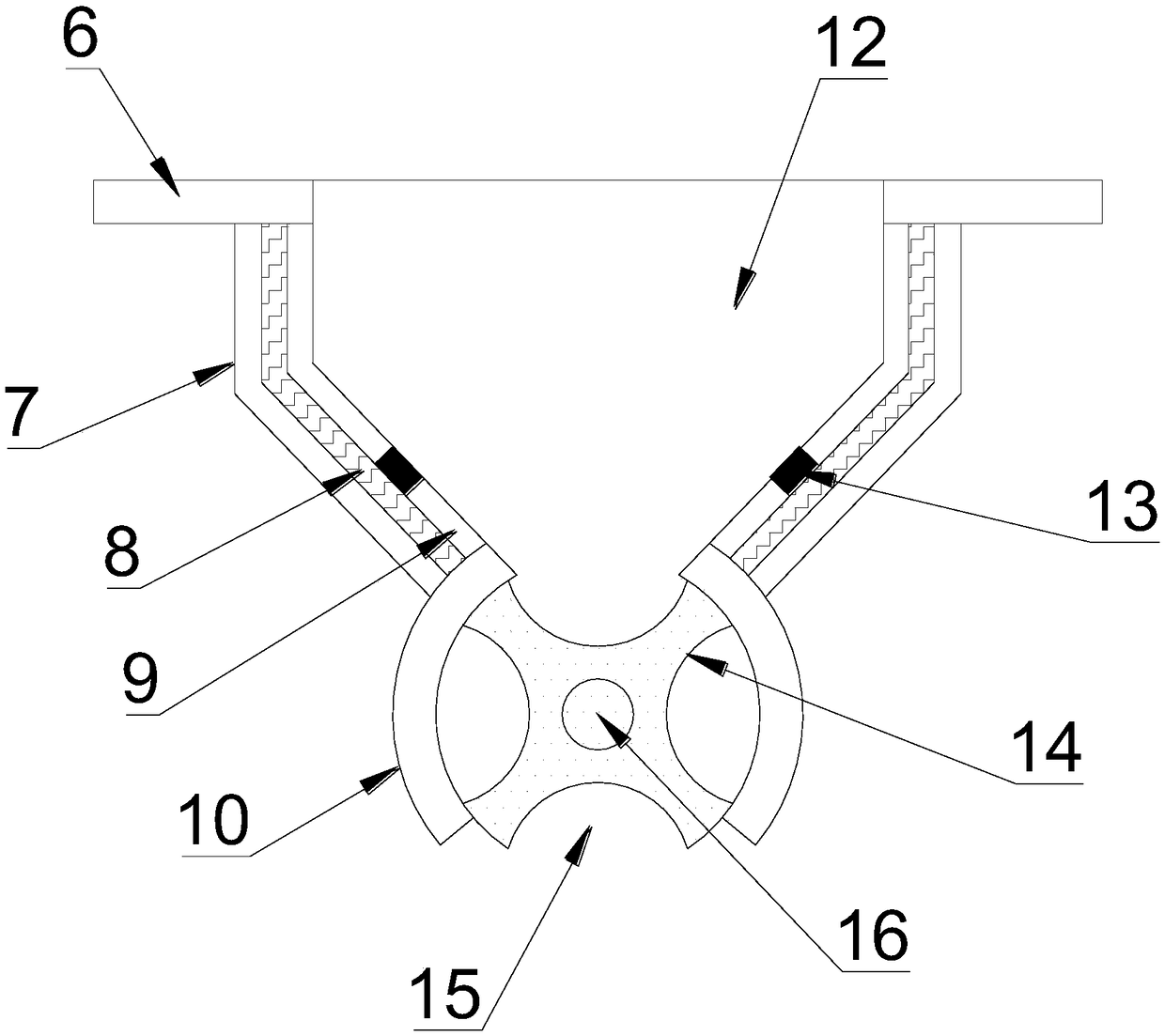

[0027] See Figure 1-3 , A preheating powder spreading device for laser selective melting of metal 3D printing, including powder supply tank 2, heat conduction cylinder 9, powder spreading tank 11, powder feeding roller 14, powder spreading filter 17, powder spreading 25 and forming Platform 26. The bottom of the forming platform 26 is provided with a powder recovery box 27 and a forming working cylinder 28. The powder recovery boxes 27 are distributed on both sides of the forming platform 26 for recovering excess powder; the forming working cylinder 28 is set at Between the powder recovery box 27 is the working area of the forming parts, which is used to realize the micro-nano-level ascending and descending movement strokes; a powder spreading mechanism and a powder supply preheating mechanism are installed above the forming platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com