High-corrosion resistance hub bearing unit and machining process

A kind of wheel hub bearing and processing technology technology, applied in the field of auto parts, can solve the problems affecting the service performance and life, insufficient anti-corrosion and anti-oxidation performance, corrosion of snow remover, etc., to improve the service life, improve the anti-oxidation and Corrosion resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

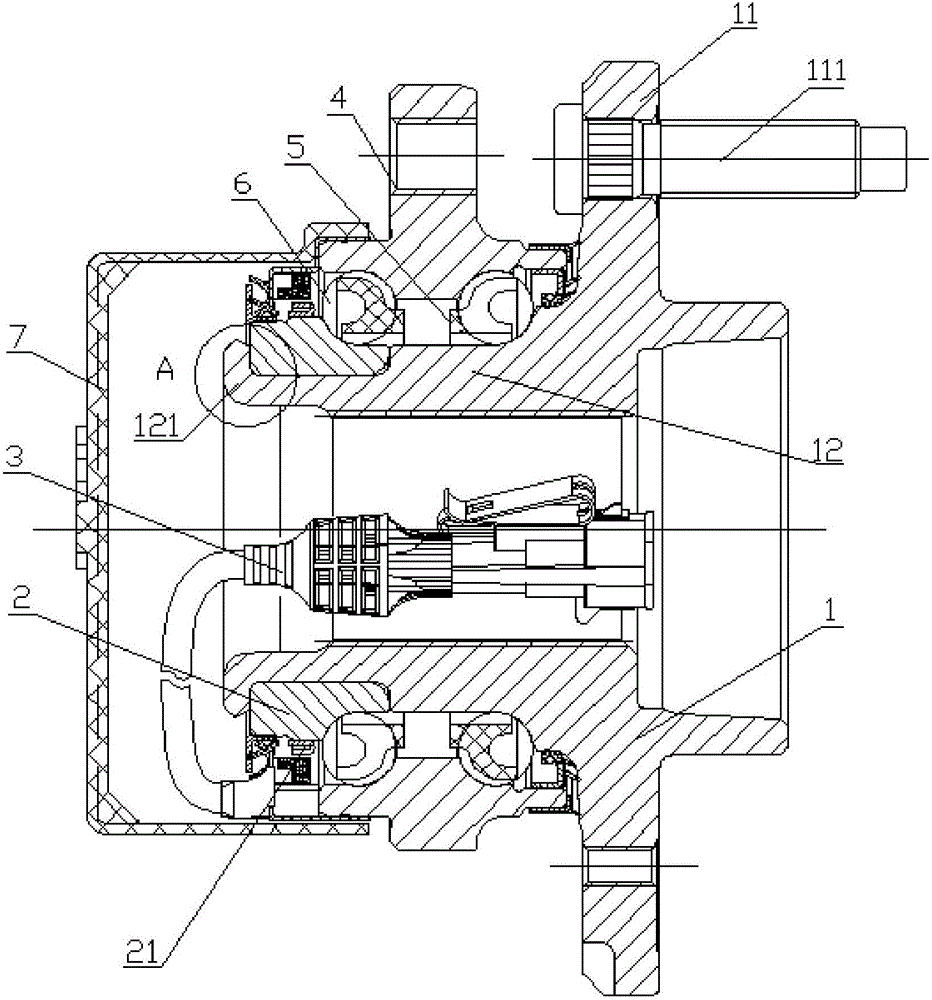

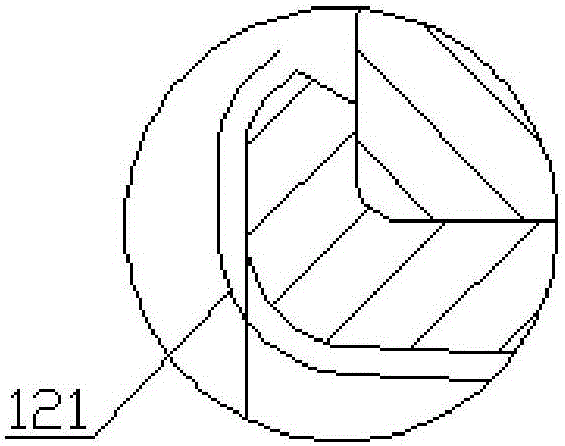

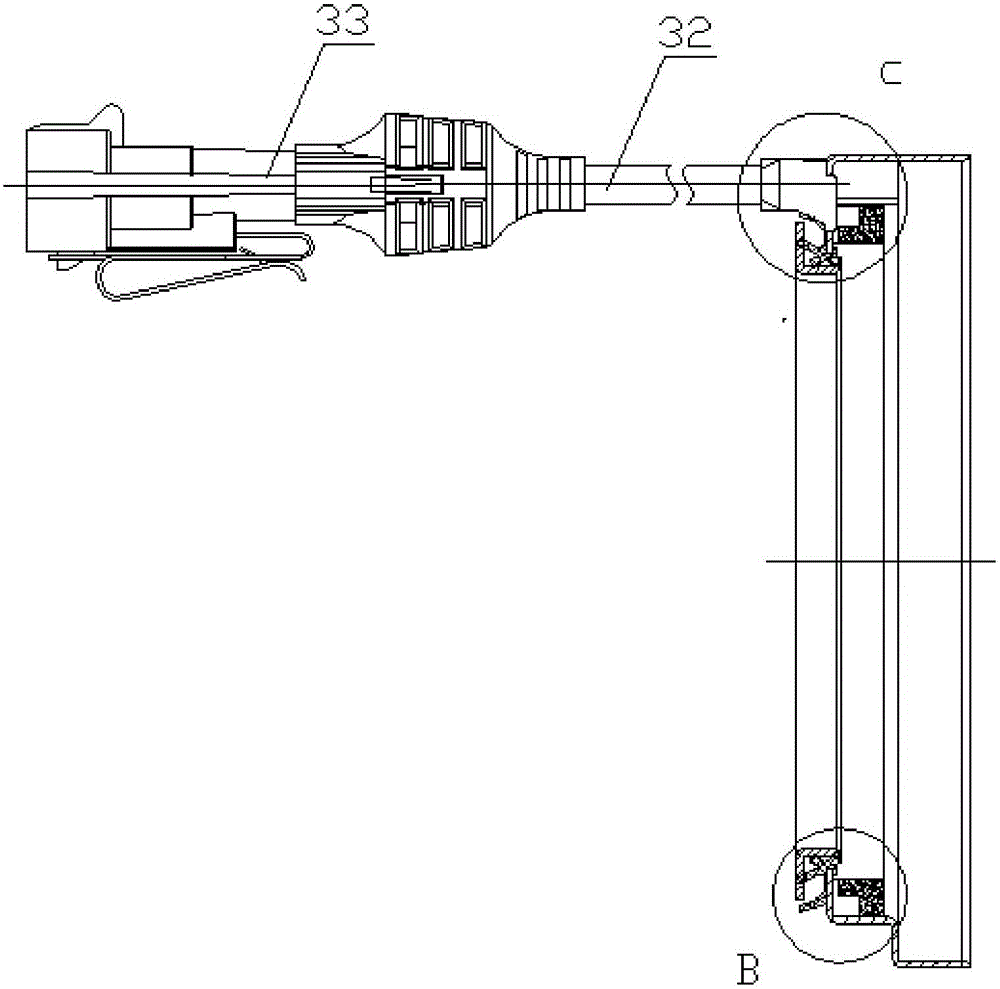

[0028] like figure 1 and figure 2 The high-corrosion-resistant hub bearing unit shown includes a flange 1 and an outer ring 4 installed on the flange 1, an inner ring 2, a wheel speed sensor 3, a cage 5, and a steel ball 6. The flange The disk 1 includes a ring flange 11 and a cylindrical portion 12 arranged on the front side of the ring flange. The ring flange 11 is uniformly distributed with fixing bolts 111 along the circumferential direction. The riveting section 121 fixed by screw riveting, the ring gear 21 is installed on the inner ring 2, the front side of the flange is provided with a dust cover 7, and the mouth of the dust cover 7 is fixed to the end of the outer ring.

[0029] Wherein, the outer surfaces of the flange 1 and the outer ring 4 are provided with a zinc-nickel coating, and the corresponding riveting section of the flange 1 is provided with a blank area of the zinc-nickel coating, that is, all hub bearing units except the riveting part of the flange T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com