Boxing machine

A box packing machine and box technology, applied in the field of rotary box packing machine, can solve the problems of low box packing efficiency, space pressure, low efficiency, etc., and achieve the effect of improving space utilization, occupying a small space, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

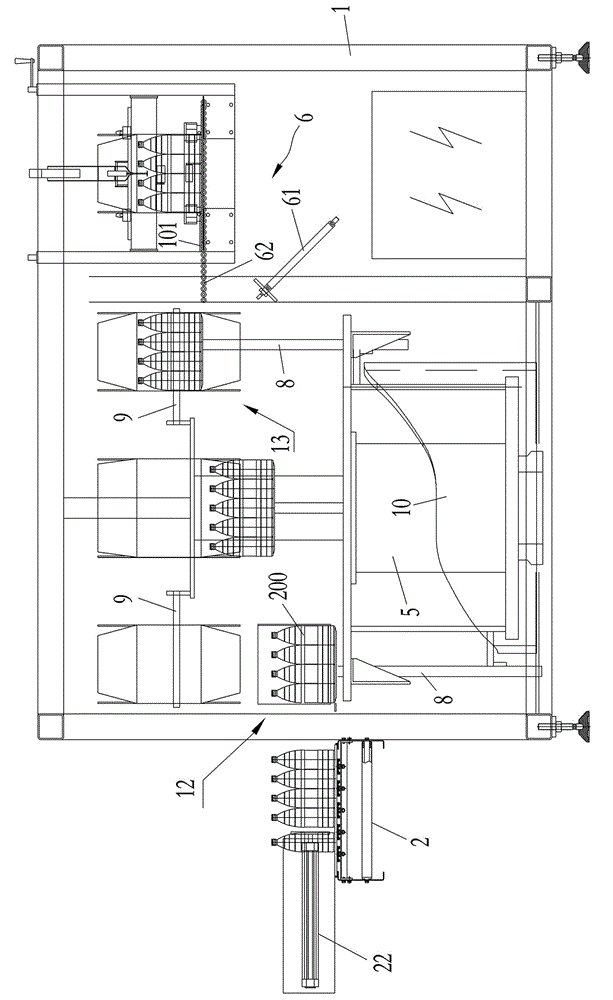

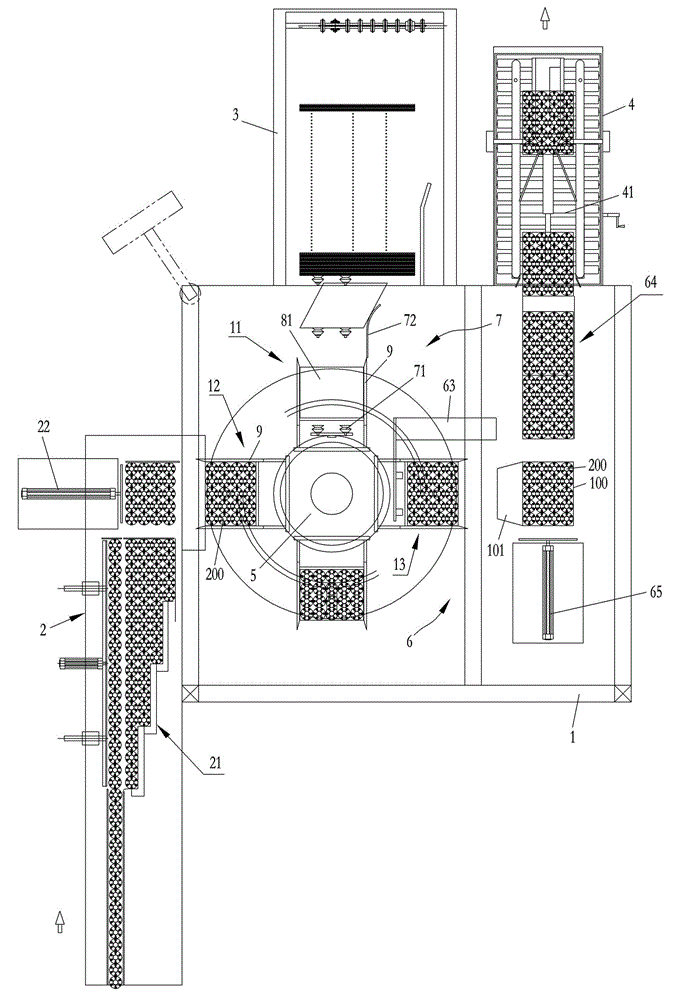

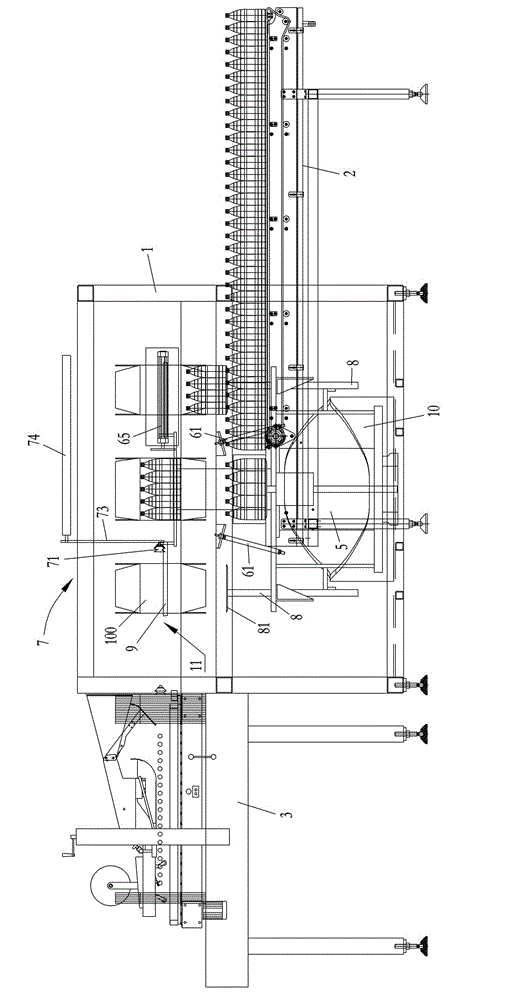

[0011] Such as Figures 1 to 5 As shown, a kind of packing machine of the present invention comprises main frame 1, product conveying device 2, cardboard conveying device 3, and sealing device 4, and described main frame 1 is provided with the rotating mechanism 5 driven by motor, folding The bottom folding mechanism 6, and the forming mechanism 7 that pulls the cardboard out from the cardboard conveying device 3 and forms it into a box 100 with both bottom and top openings, the rotating mechanism 5 is distributed with lifting assemblies 8 that rotate with it, so The number of lifting components mentioned above can be set as required, such as figure 2 The situation of four groups is shown, which are evenly distributed around the rotating shaft of the rotating mechanism 5. The top of the lifting assembly 8 is fixed with a pallet 81 for placing the product group 200 conveyed by the product conveying device 2, and the rotating mechanism 5 is above the corresponding pallet 81. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com