Bottle blanking mechanism of drop type packing machine

A cartoning machine and drop technology, applied in the direction of packaging bottles, packaging, transportation and packaging, etc., can solve the problems of high difficulty in adjustment and installation, bottle deformation, time-consuming and labor-intensive problems, and achieve bottle drop mode and easy operation and installation And the effect of convenient maintenance and simple way of dropping bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the drawings and the best embodiments.

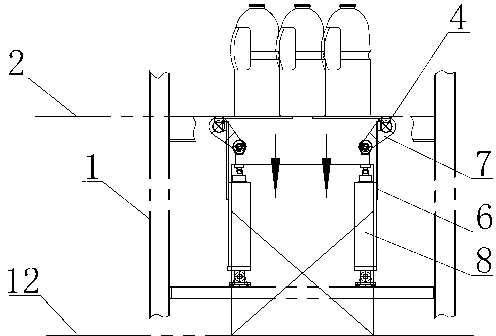

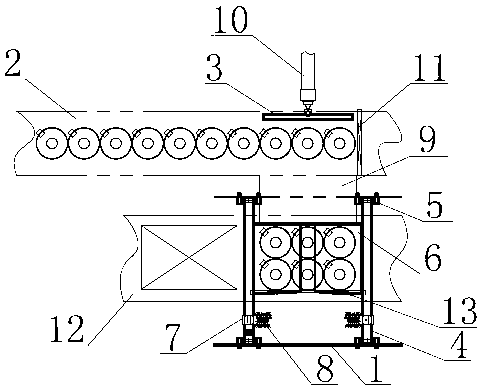

[0011] Such as figure 1 , figure 2 As shown, the bottle dropping mechanism in the drop boxing machine includes a frame 1. A bottle pushing plate 3 connected to a bottle pushing plate driving device is provided on one side of the bottle conveying platform 2, and the other of the bottle conveying platform 2 A pair of turning shafts 4 are provided on the side. Both ends of the pair of turning shafts 4 are respectively movably supported in the bearing housing 5 on the frame 1. A turning plate 6 is fixedly connected to the two turning shafts 4, and two turning shafts 4 is also fixedly connected to a connecting rod 7, and the ends of the two connecting rods 7 are respectively connected to the ends of the piston rods 81 of the two inverting cylinders 8 installed on the frame 1. Driven, the two turning shafts 4 can respectively rotate in the bearing housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com