Cylindrical strip material stacking container loader

A technology of stacking box machine and material layer, applied in packaging, single object, transportation and packaging, etc., can solve the problems of low reliability and insufficient number of boxes, and achieve improved production capacity, simple structure, and accurate number of boxes. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the patent of the present invention is described in further detail.

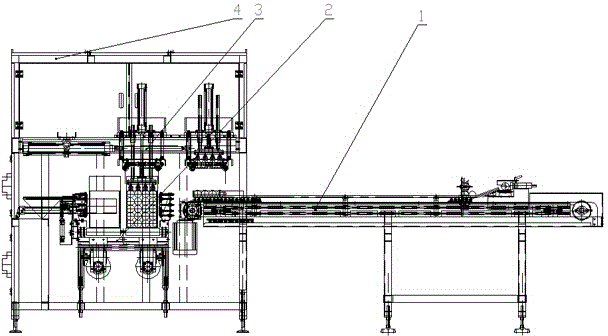

[0018] see figure 1 , the present invention a kind of cylindrical strip material lamination packing machine comprises material conveying and sorting part 1; Empty case feeding, positioning and full case sending part 2;

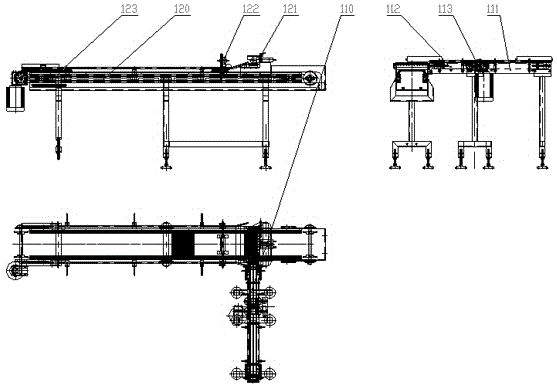

[0019] see figure 2 , the conveying and sorting arrangement of cylindrical strip materials includes a straight strip conveying device 110, and a horizontal strip sorting and arranging conveying device 120; The sorting and arranging conveying device 120 further includes a push-down rolling mechanism 121 , an alignment star wheel 122 , and a skid roller chain conveying device 123 .

[0020] see figure 2 , the round strip material is sent to the constant velocity conveying section 111 in a continuous straight direction, and the conveying speed of the constant velocity conveying section 111 is basically equal to the velocity of the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com