Automatic box dividing mechanism of wine bottle box filling machine

A wine bottle cartoning machine and automatic technology, which is applied in the directions of packaging, bottle packaging, transportation and packaging, can solve the problem that the wine bottle array cannot realize automatic sub-boxing and packaging, etc., and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

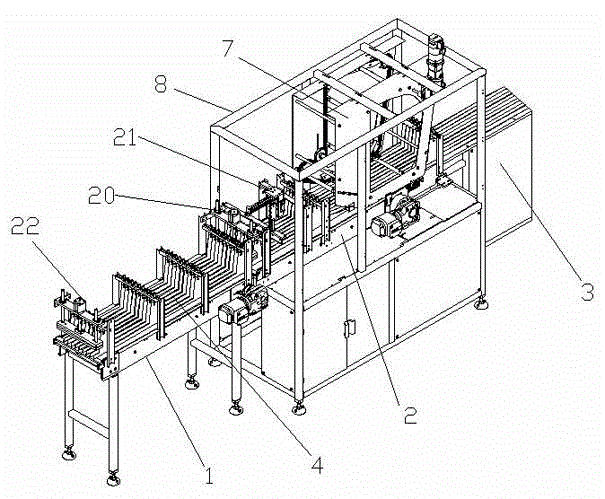

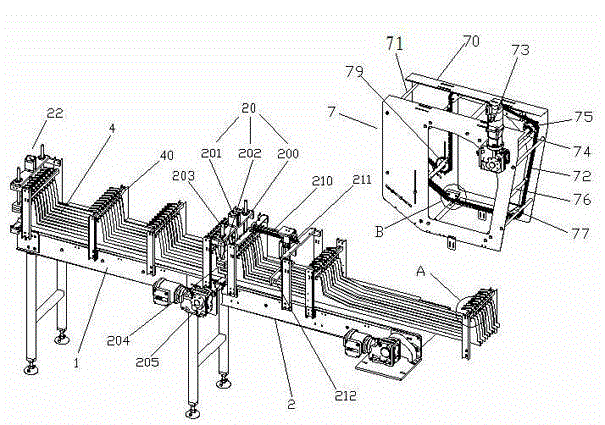

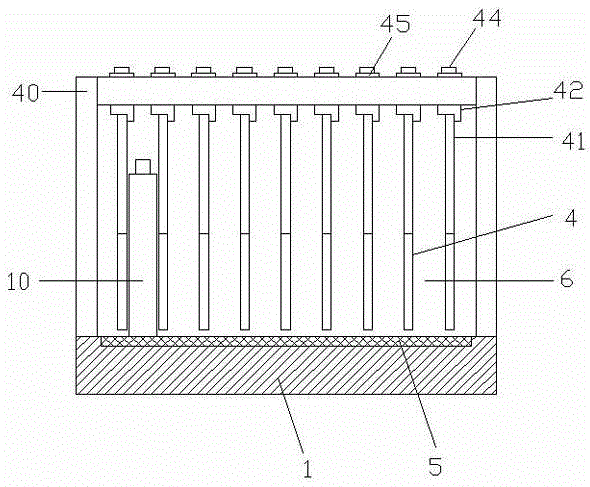

[0030] Such as figure 1 A kind of wine bottle cartoning machine automatic box sorting mechanism shown, comprises stacking conveyor belt platform 1, box sorting conveyor belt platform 2, manual shelf platform 3 connected successively, stacking conveyor belt platform, box sorting conveyor belt platform are respectively set There is a conveyor belt 5, and nine partitions 4 perpendicular to the conveyor belt are arranged above the conveyor belt, such as image 3 As shown, eight feed channels 6 are formed parallel to each other between the partitions, and a gap is provided between the bottom of the partition and the conveyor belt; as Figure 5 As shown, several gantry brackets 40 are arranged on the stacking conveyor belt platform 1 and the case-dividing conveyor belt platform 2, the upper end of the partition plate extends to form a connecting piece 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com