Packing machine

A technology of packing machines and racks, applied in the field of packing machines, can solve the problems of easy shaking, easy shaking, and increased power load when the translation frame moves horizontally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

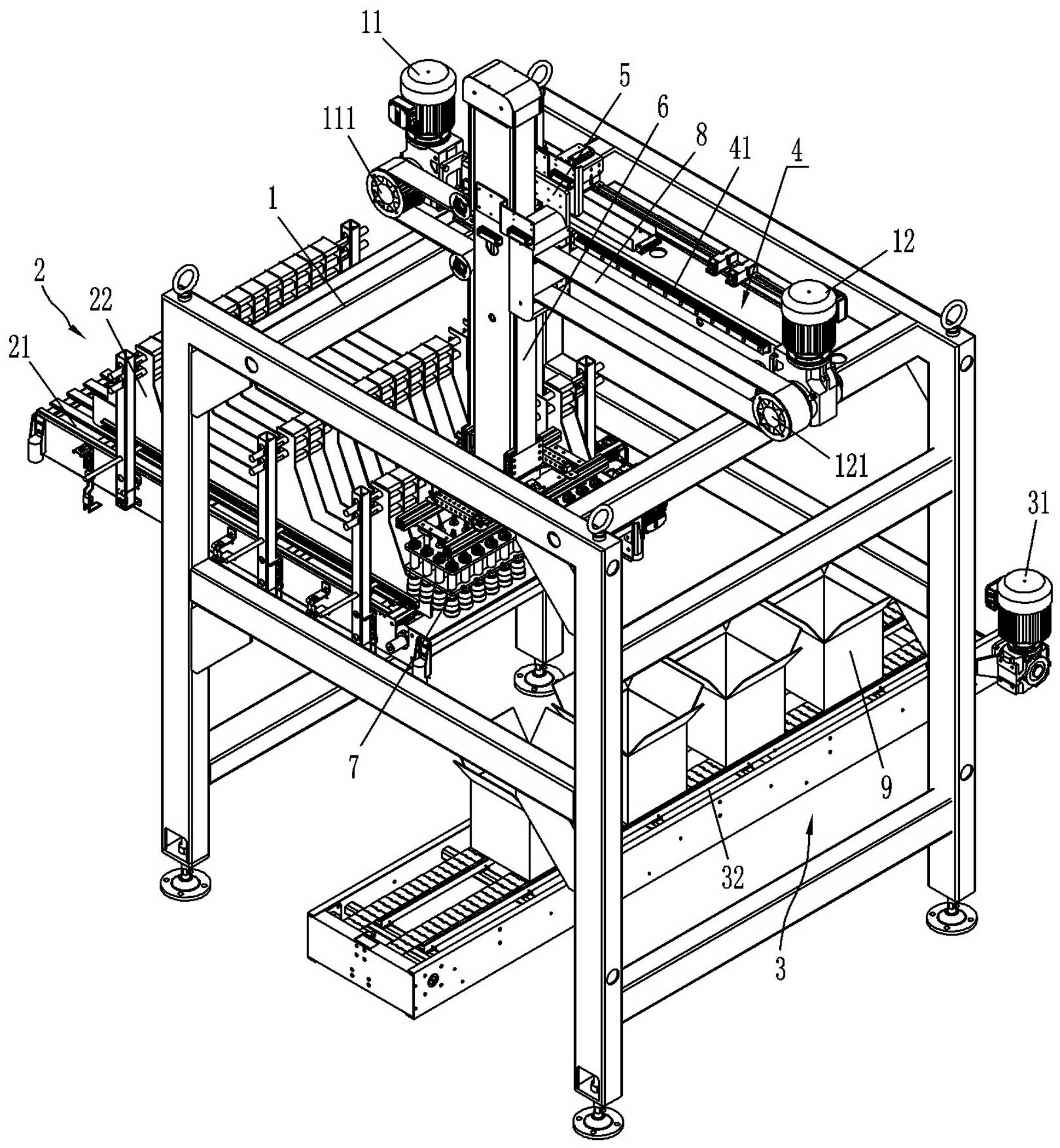

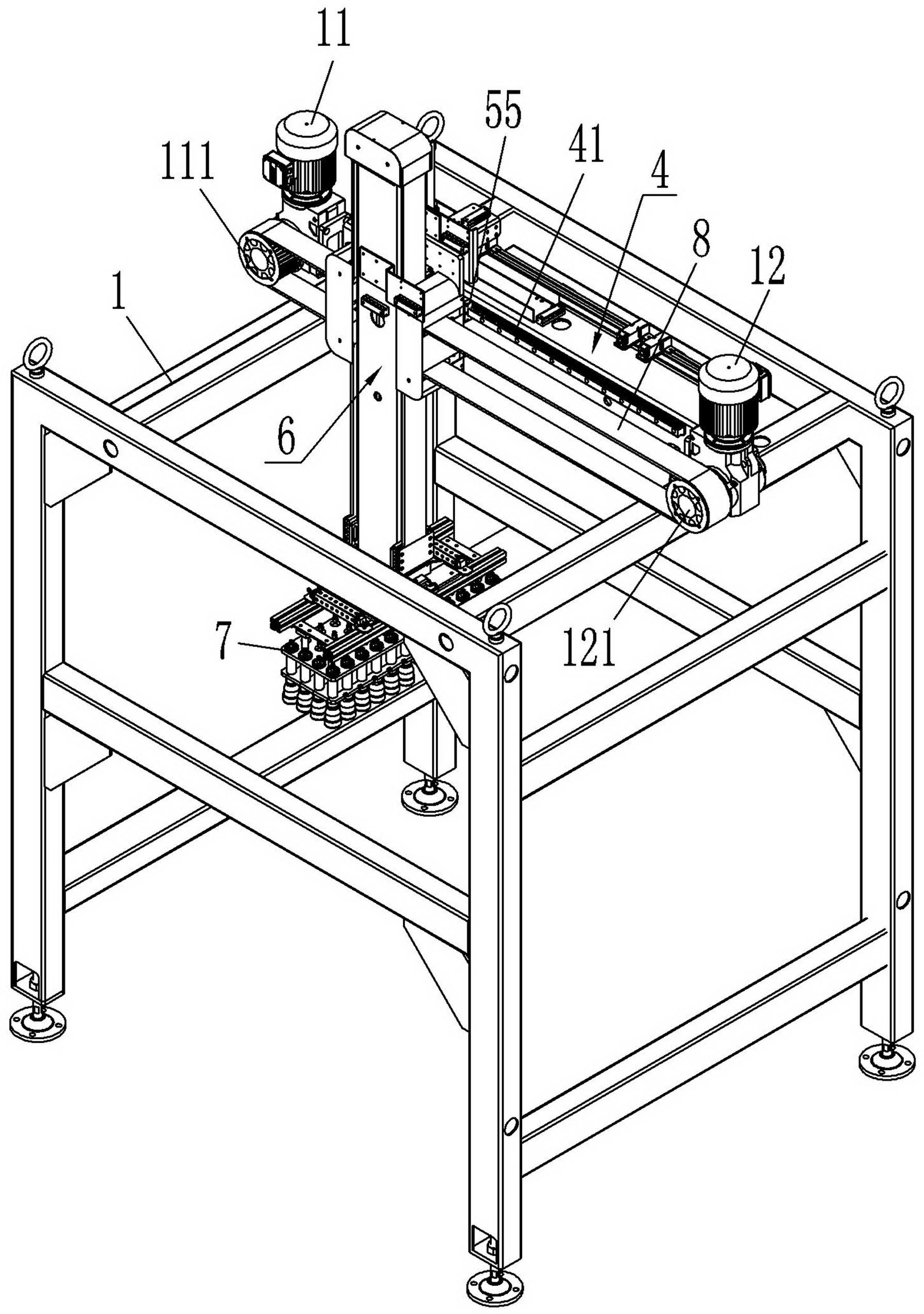

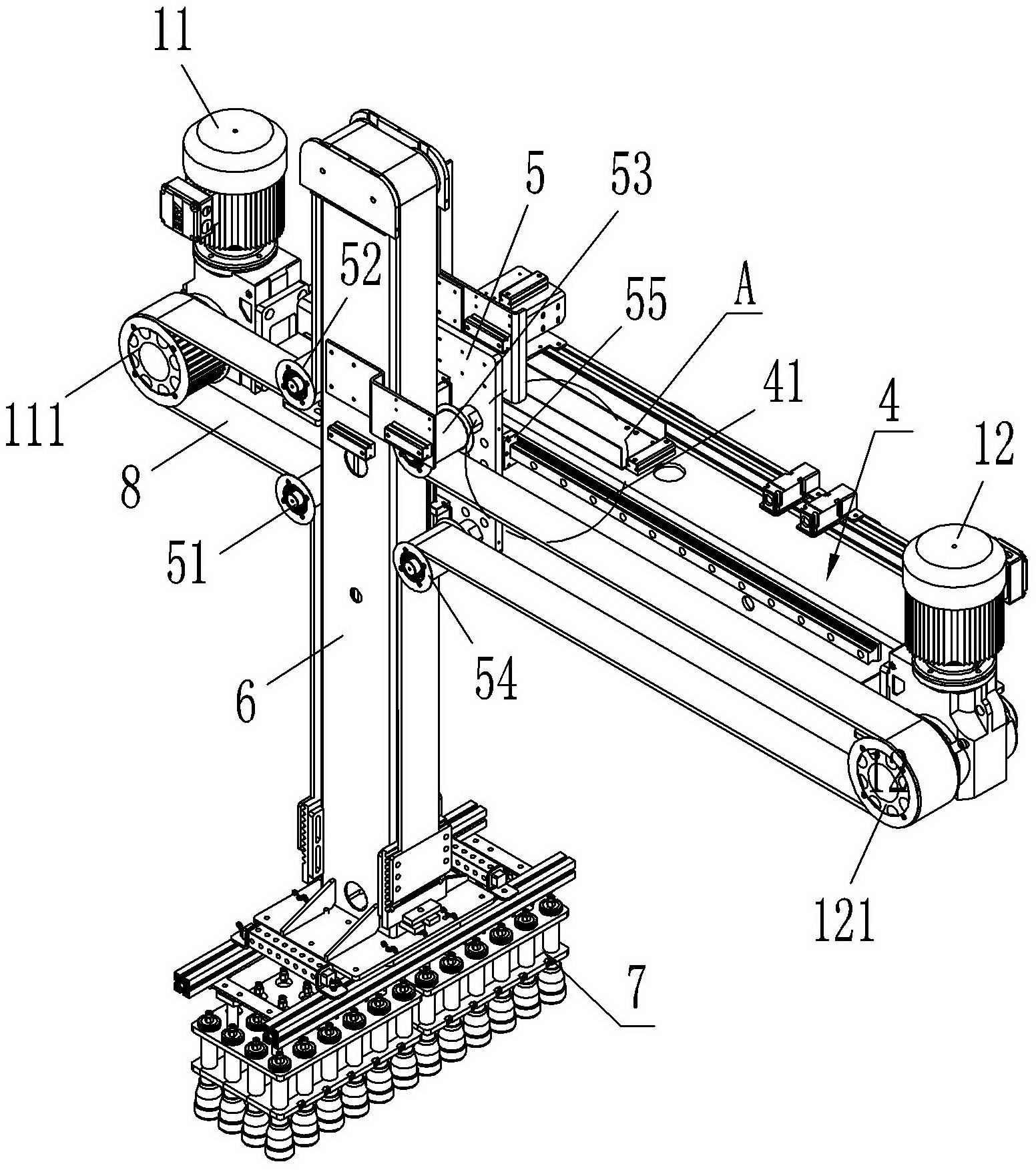

[0015] Such as Figures 1 to 8 As shown, a kind of packing machine of the present invention comprises frame 1, and the bottom of frame 1 has bottle conveying device 2 and case conveying device 3, and this bottle conveying device 2 and conveying case device 3 are prior art , wherein, the bottle conveying device 2 mainly includes a bottle conveying belt 21 driven by a motor (not shown in the figure) for conveying bottles, and a bottle sorting mechanism 22 for sorting out the bottles conveyed by the bottle conveying belt 21. Case device 3 then mainly comprises motor 31, and is driven by motor 31, is used to transport case belt 32 to packing case 9, here no longer to the concrete structure of conveying bottle device 2 and case conveying device 3 and specific working principle To repeat, the top of the frame 1 is equipped with a translation frame 5 that can slide between the bottle conveying device 2 and the case conveying device 3, and the translation frame 5 is equipped with a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com