Box filling machine

A cartoning machine, the technology of the cartoning machine, applied in the direction of packaging, transportation and packaging, single objects, etc., can solve the problems of high production cost and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

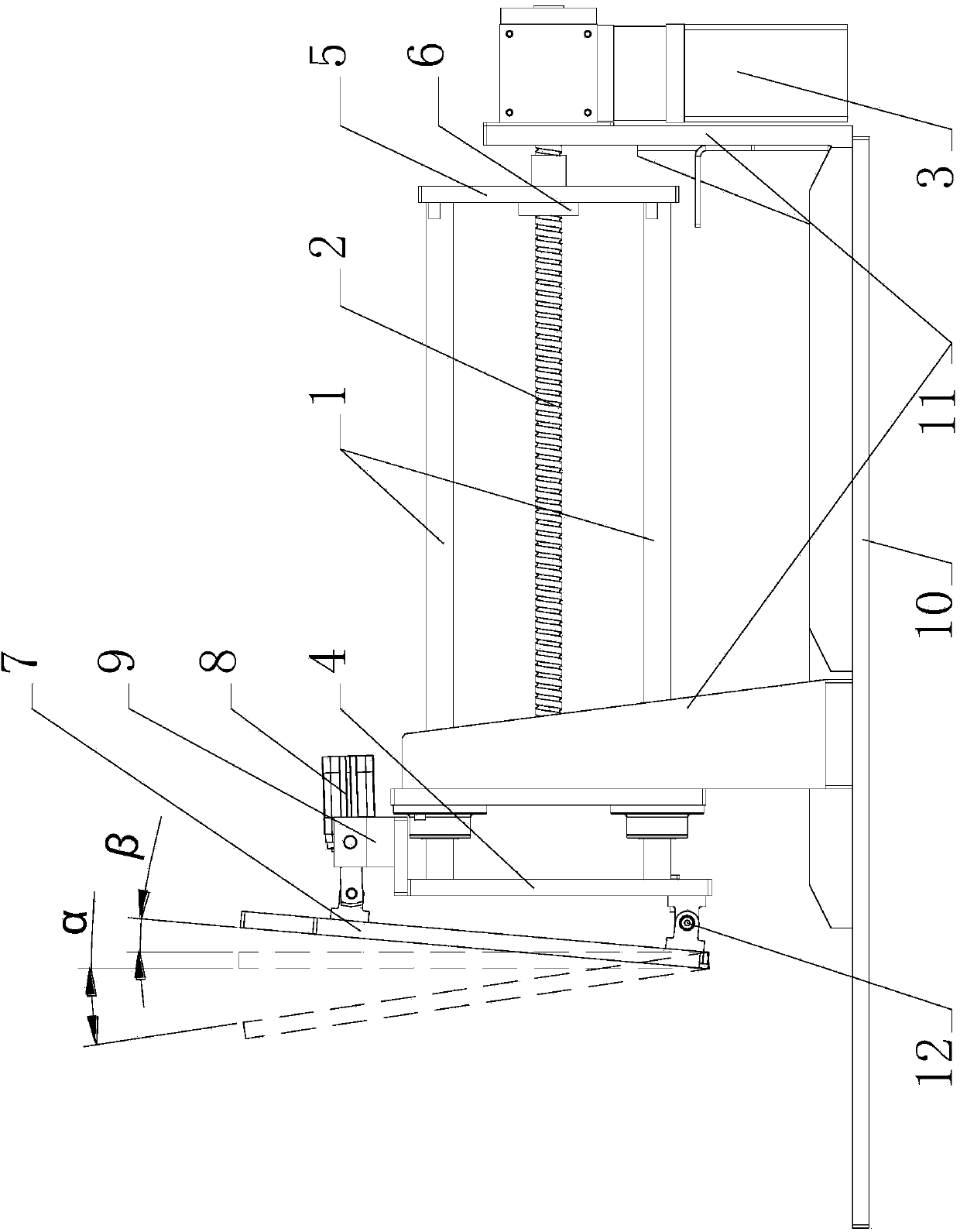

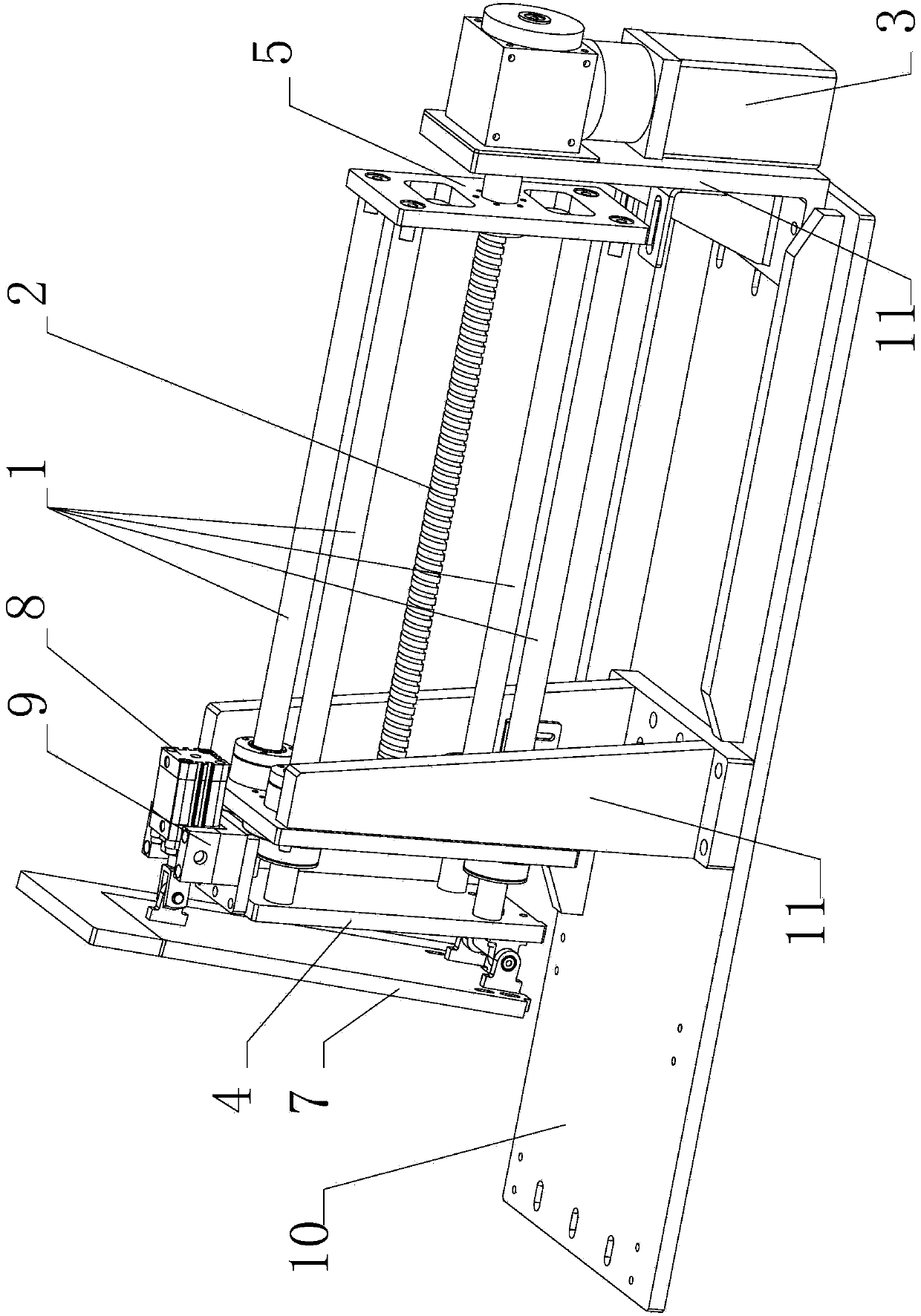

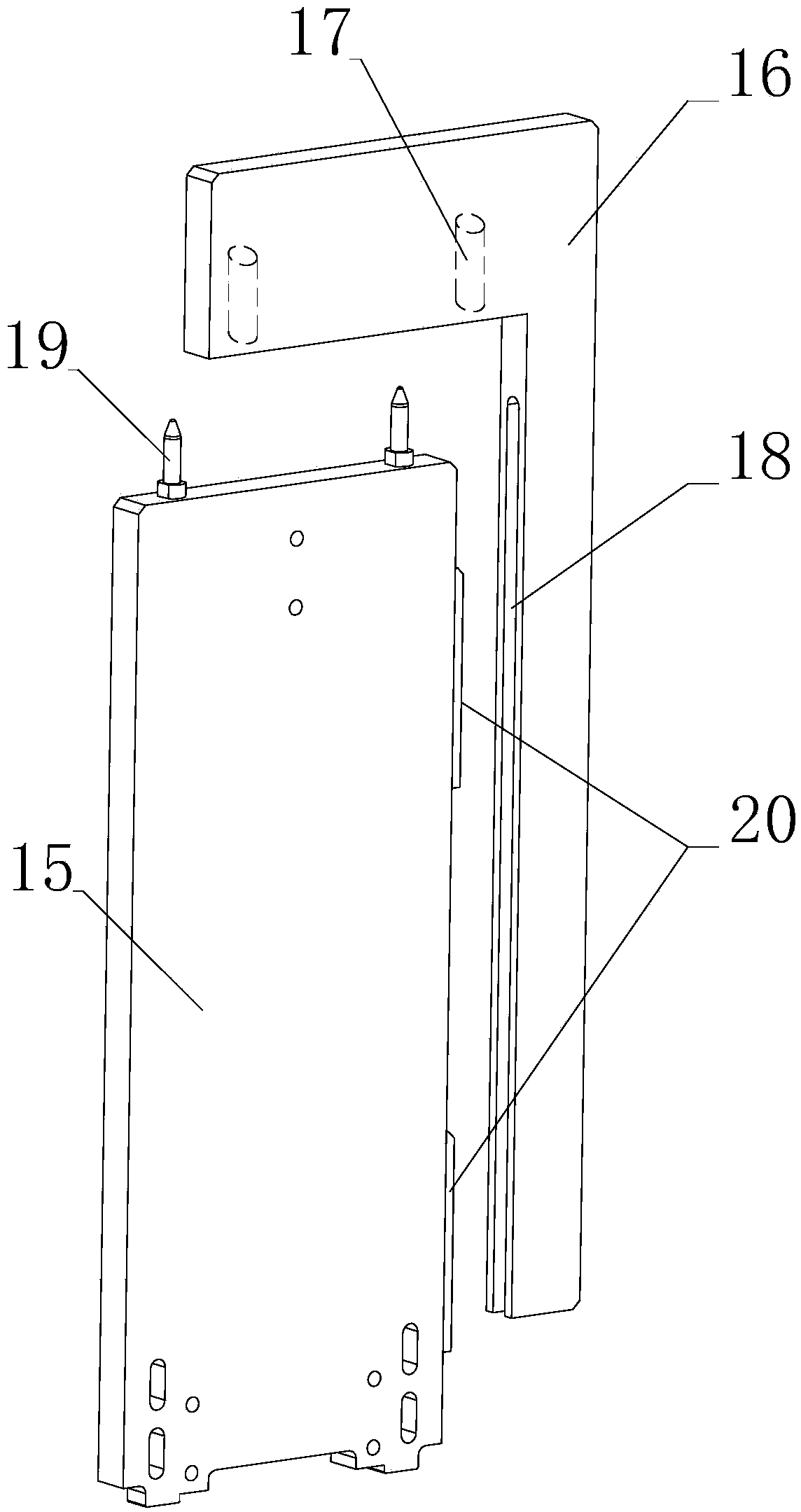

[0042] The first embodiment of the present invention.

[0043] like Figure 24 As shown, the case packer is provided with a frame on which a packing case roller conveying line 59, a product conveyor belt 60, a suction bag robot 61, and an accommodating device 55 are arranged. The package suction robot is set on the top of the frame, the packaging line roller conveyor line is set on the bottom of the frame, and the product conveyor belt is installed on the frame and is located between the package suction robot and the packaging line roller conveyor line. The suction bag robot is equipped with a movable mechanical arm, and a suction cup is provided at the end of the robotic arm. The suction cup is connected to the trachea, and can suck milk powder in bags during work. The range of motion of the mechanical arm of the suction bag robot includes the position of the upper part of the product conveyor belt. After sucking the bagged milk powder from the product conveyor belt, the bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com